-

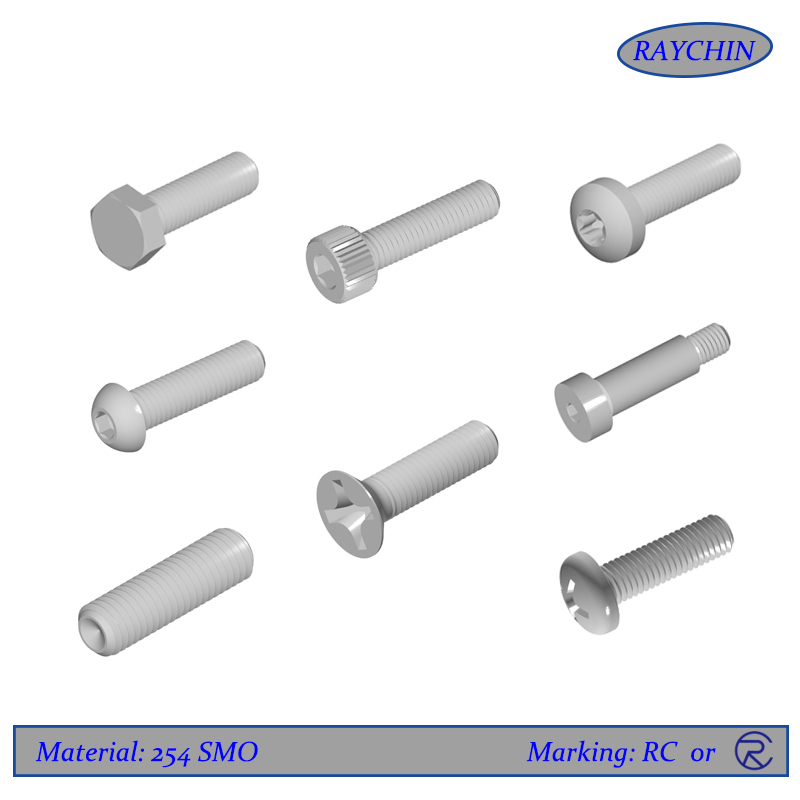

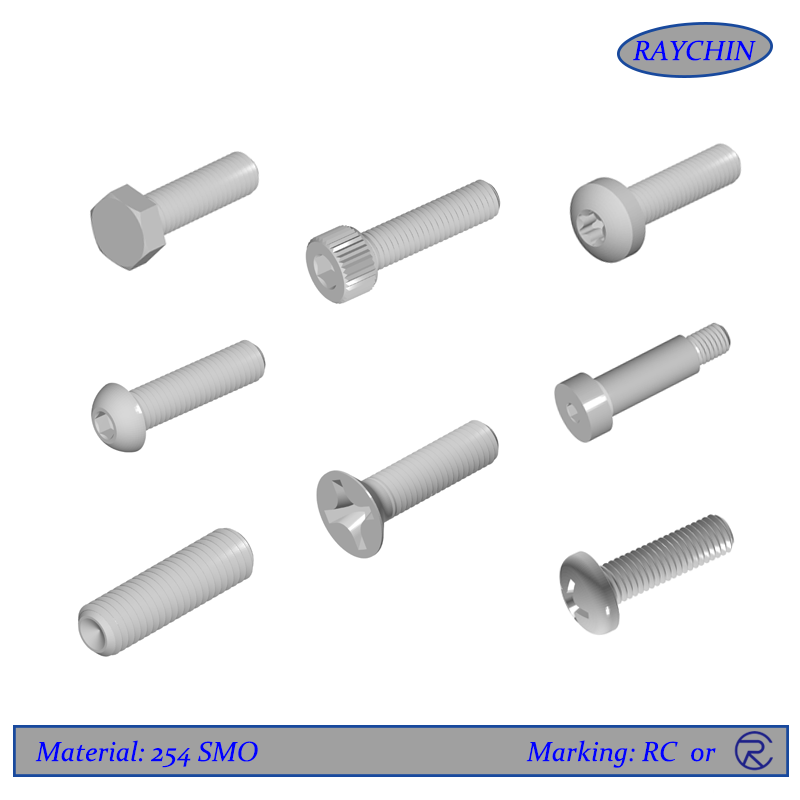

254 SMO Fasteners

254 SMO (1.4547) fasteners are made of a high-end stainless steel alloy that was developed for resistance to saltwater and chloride corrosion. This 6-Moly (6% Molybdenum) alloy has good localized corrosion resistance and 254 SMO provides much higher strength than other austenitic stainless steels. 254 SMO bolts are an ideal choice for high chloride environments including brackish water, seawater and other applications that demand heavy use of chlorines and chlorides. Compared to sister 6-Moly alloy AL6XN, 254 SMO fasteners offer slightly less high temperature stability corrosion resistance and strength.

Send Email Details -

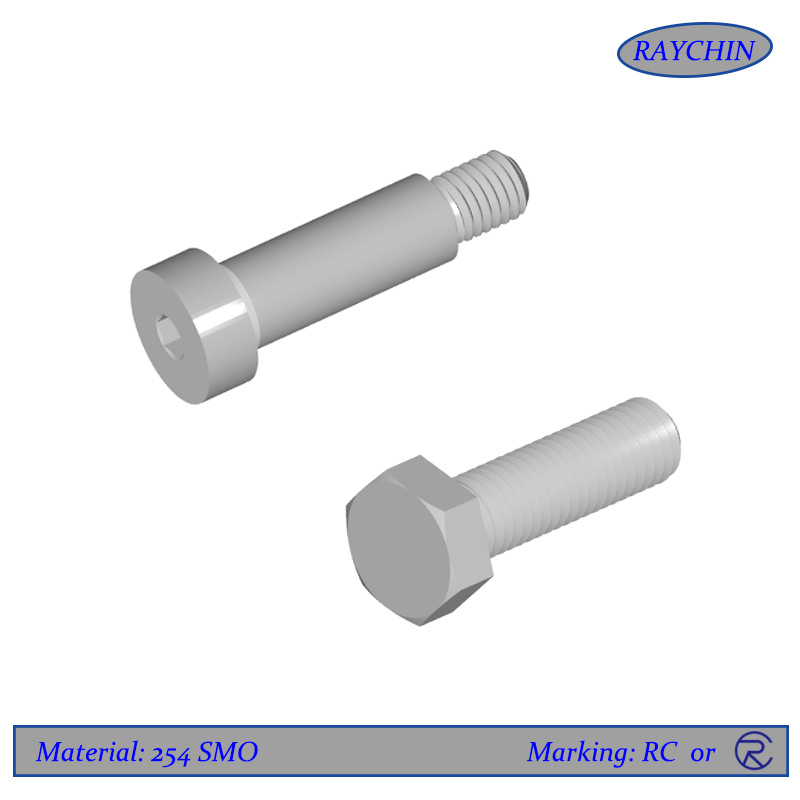

254 SMO Bolts

254 SMO hex head bolts are similar to hex head cap screws except without the washer face under the head. Hex bolts are a good choice when high clamping force needed for easily accessible applications.

Send Email Details

254 SMO hex head bolts are similar to hex head cap screws except without the washer face under the head. Hex bolts are a good choice when high clamping force needed for easily accessible applications. -

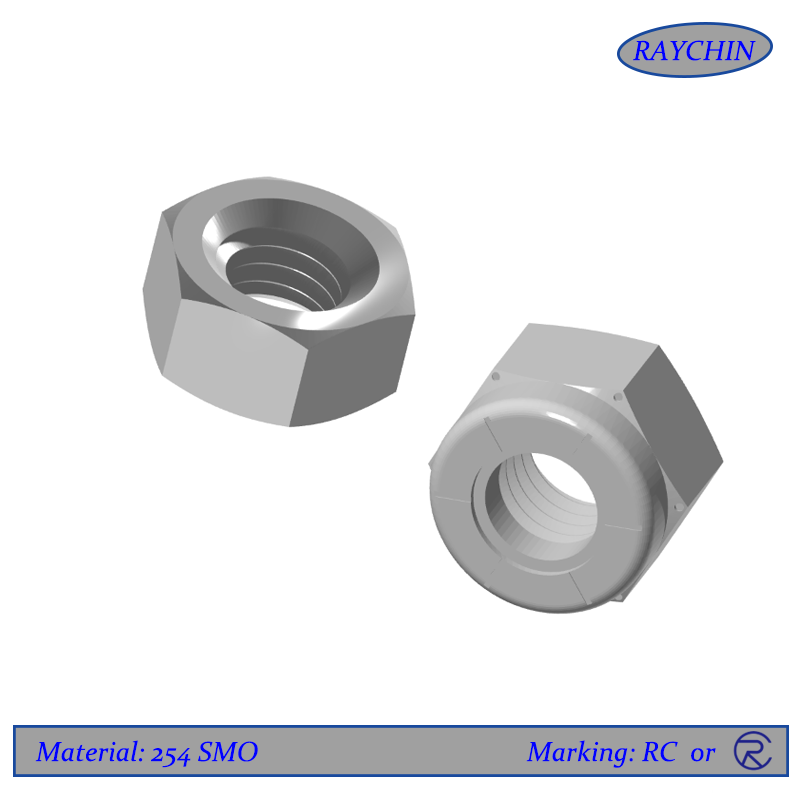

254 SMO Nuts

254 SMO hex nuts are available in the followin styles: finished hex nuts, jam nuts and heavy hex nuts

Send Email Details -

254 SMO Screws

12 Point Screws254 SMO 12 point screws are ideal when you need higher torque than socket head cap screws offer. These screws are available in 1/4" diameter or larger. The only drawback is 12 point screws are less economical and require a higher minimum quantity due to the complexity of production.• IFI-115

Send Email Details

• MIL SPEC

• DIN 34822

• DIN 34821

Button Head Cap ScrewsFor applications that require a wide clamping area and low profile fastener 254 SMO button head cap screws are a good choice. Button head screws are also used for fastening a material that is too thin to counter bore.• ASME B18.3

• ASME 18.3.4M

• DIN 7380 / ISO 7380

Flat Head Screws254 SMO flat head screws come standard with an 82° countersink angle. Other angles ranging from 60° -120° can also be made upon request. 254 SMO flat heads can be made with slotted or socket drivers. Phillips, torx and tamperproof drivers are also available depending on size, quantity and material.• ASME B18.3

• ASME B18.3.6

• DIN 963 / ISO 2009

• DIN 965 / ISO 7046

• DIN 7991 / ISO 10642

Hex Head Cap Screws254 SMO hex head cap screws are one of the most commonly used styles. They feature an added washer face that hex head bolt do not have. This washer face provides tighter dimensional tolerances. 254 SMO hex head cap screws provide high clamping force and easy access.• ASME B18.6.3

• DIN 931 / ISO 4014

• DIN 933 / ISO 4017

• DIN 961 / ISO 8676

Pan Head ScrewsPan head screws have a rounded head and most commonly have a slotted driver. 254 SMO pan heads are best for small diameter and low torque applications.• ASME B18.6.3

• DIN 7985

• DIN 921

• DIN 85 / ISO 1580

• DIN 84 / ISO 1207

(cheese head)

• DIN 966 / ISO 7047

(raised counter sunk) -

254 SMO Hex Bolts

254 SMO hex head bolts are similar to hex head cap screws except without the washer face under the head. Hex bolts are a good choice when high clamping force needed for easily accessible applications.

Send Email Details -

254 SMO 12 Point Screws

254 SMO 12 point screws are ideal when you need higher torque than socket head cap screws offer. These screws are available in 1/4" diameter or larger. The only drawback is 12 point screws are less economical and require a higher minimum quantity due to the complexity of production.

Send Email Details -

254 SMO Vented Screws

254 SMO vented screws provide a way to out-gas application contaminents through a vertical hole drilled from the screw head through the threaded shaft. Vented screws are ideal for vacuums / high vacuums. Nimonic vented screws are available a variety of head styles.

Send Email Details -

254 SMO Flat Washers

254 SMO washers are availble in several specifications including SAE, USS, DIN, MilSpec, oversized, and custom per print

Send Email Details -

254 SMO Lock Washers

254 SMO washers are available as a split lock washer style.

Send Email Details