-

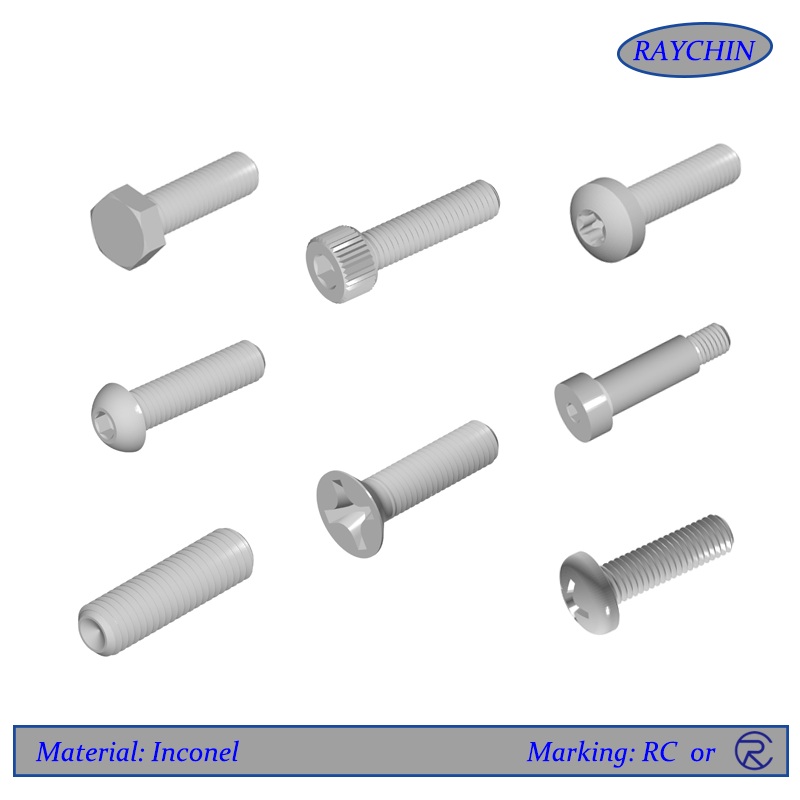

Inconel Fasteners

Inconel fasteners, like Inconel 600, 601, 625, 686, 718, 725 & X750 fasteners, are a family of nickel-chromium-molybdenum alloys used for their high strength at elevated temperatures and good corrosion resistance. Because of its high thermal stability, Inconel can be used in service temperatures ranging from cryogenic to 2200°F (982°C). The high alloy content of Inconel fasteners enable it to withstand a wide variety of severe corrosive environments. In mild environments, such as the atmosphere, sea water, neutral salts, and alkaline media, there is almost no attack to Inconel fasteners. In more severe corrosive environments the combination of nickel and chromium provides resistance to oxidizing chemicals, whereas the high nickel and molybdenum contents supply resistance to nonoxidizing environments.

Send Email Details

Because Inconel fasteners offer a good balance of corrosion resistance, temperature stability, toughness and strength they are often a material of choice for chemical processing, aerospace, marine, electronics and oil & gas.

Because Inconel fasteners offer a good balance of corrosion resistance, temperature stability, toughness and strength they are often a material of choice for chemical processing, aerospace, marine, electronics and oil & gas. -

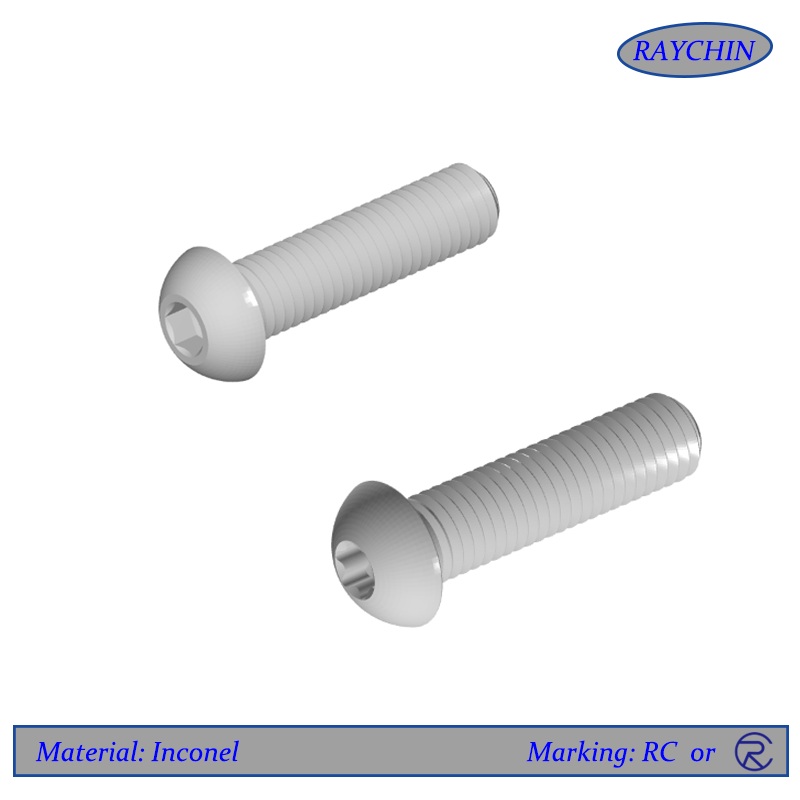

Inconel Button Head Cap Screws

Inconel® button head cap screws, like Inconel 600, 601,625,686,718 & 725 screws, are a family of nickel-chromium-molybdenum alloys used for their high strength at elevated temperatures and good corrosion resistance. Because of its high thermal stability, Inconel can be used in service temperatures ranging from cryogenic to 2200°F (982°C). The high alloy content of Inconel button head cap screws enable it to withstand a wide variety of severe corrosive environments. In mild environments, such as the atmosphere, sea water, neutral salts, and alkaline media, there is almost no attack to Inconel screws. In more severe corrosive environments the combination of nickel and chromium provides resistance to oxidizing chemicals, whereas the high nickel and molybdenum contents supply resistance to nonoxidizing environments.

Send Email Details -

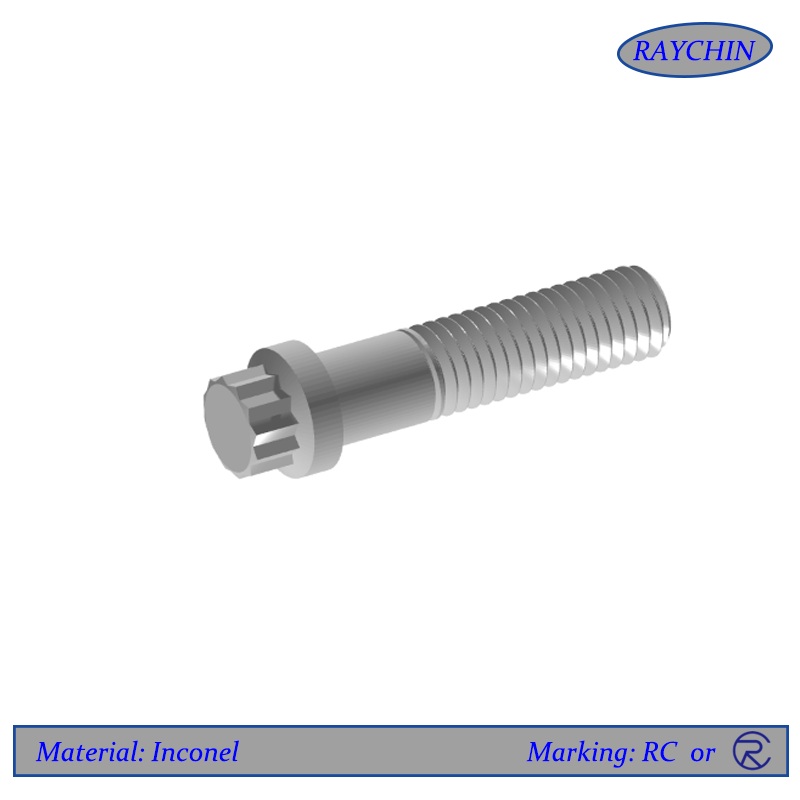

Inconel 12 Point Screws

Inconel® 12 point screws, like Inconel 600, 601,625,686,718 & 725 screws, are a family of nickel-chromium-molybdenum alloys used for their high strength at elevated temperatures and good corrosion resistance. Because of its high thermal stability, Inconel can be used in service temperatures ranging from cryogenic to 2200°F (982°C). The high alloy content of Inconel screws enable it to withstand a wide variety of severe corrosive environments. In mild environments, such as the atmosphere, sea water, neutral salts, and alkaline media, there is almost no attack to Inconel 12 point screws. In more severe corrosive environments the combination of nickel and chromium provides resistance to oxidizing chemicals, whereas the high nickel and molybdenum contents supply resistance to nonoxidizing environments.

Send Email Details -

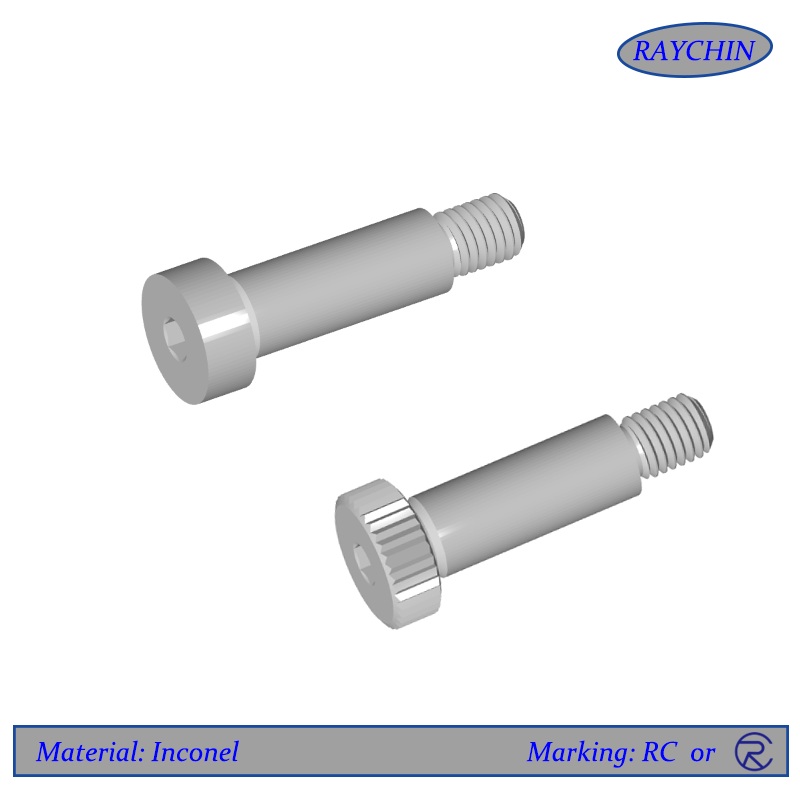

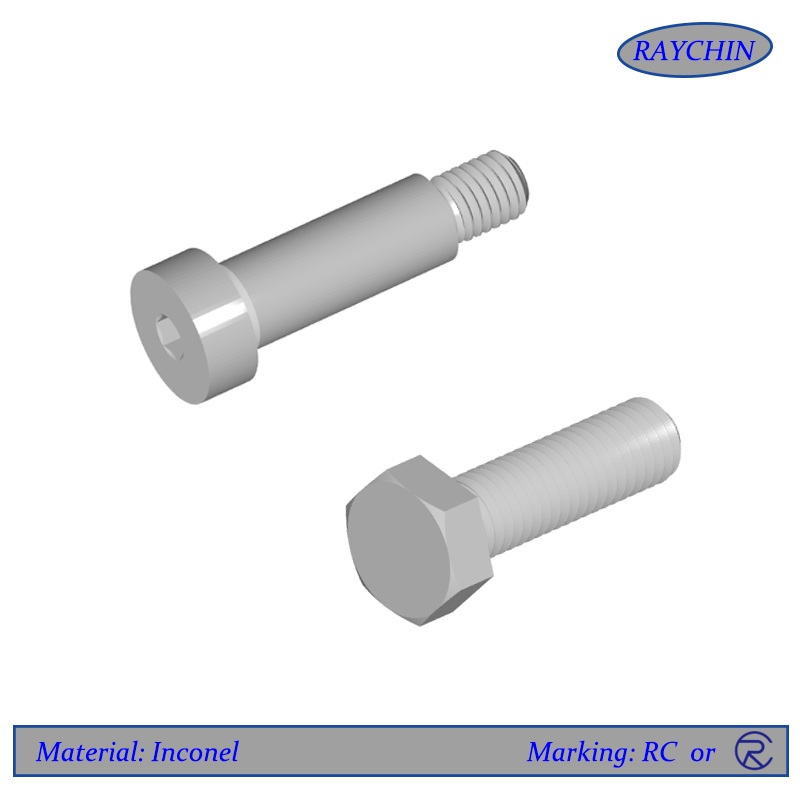

Inconel Shoulder Bolts

Inconel® shoulder bolts, like Inconel 600, 601,625,686,718 & 725 bolts, are a family of nickel-chromium-molybdenum alloys used for their high strength at elevated temperatures and good corrosion resistance. Because of its high thermal stability, Inconel can be used in service temperatures ranging from cryogenic to 2200°F (982°C). The high alloy content of Inconel bolts enable it to withstand a wide variety of severe corrosive environments. In mild environments, such as the atmosphere, sea water, neutral salts, and alkaline media, there is almost no attack to Inconel bolts shoulder. In more severe corrosive environments the combination of nickel and chromium provides resistance to oxidizing chemicals, whereas the high nickel and molybdenum contents supply resistance to nonoxidizing environments.

Send Email Details -

Inconel Bolts

Inconel bolts, like Inconel 600, 601,625,686,718 & 725 bolts, are a family of nickel-chromium-molybdenum alloys used for their high strength at elevated temperatures and good corrosion resistance. Because of its high thermal stability, Inconel can be used in service temperatures ranging from cryogenic to 2200°F (982°C). The high alloy content of Inconel bolts enable it to withstand a wide variety of severe corrosive environments. In mild environments, such as the atmosphere, sea water, neutral salts, and alkaline media, there is almost no attack to Inconel bolts. In more severe corrosive environments the combination of nickel and chromium provides resistance to oxidizing chemicals, whereas the high nickel and molybdenum contents supply resistance to nonoxidizing environments.

Send Email Details

Because Inconel bolts offer a good balance of corrosion resistance, temperature stability, toughness and strength they are often a material of choice for chemical processing, aerospace, marine, electronics and oil & gas. -

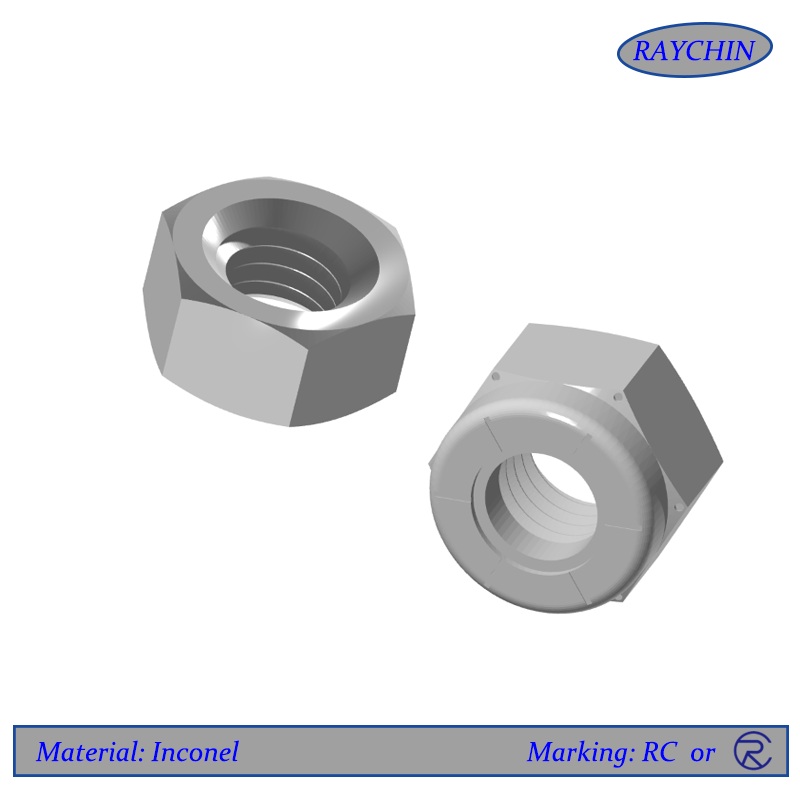

Inconel Nuts

Inconel® nuts and lock nuts, like Inconel 600, 601,625, 686, 718 & 725 nuts, are a family of nickel-chromium-molybdenum alloys used for their high strength at elevated temperatures and good corrosion resistance. Because of its high thermal stability, Inconel can be used in service temperatures ranging from cryogenic to 2200°F (982°C). The high alloy content of Inconel nuts enable it to withstand a wide variety of severe corrosive environments. In mild environments, such as the atmosphere, sea water, neutral salts, and alkaline media, there is almost no attack to Inconel nuts. In more severe corrosive environments the combination of nickel and chromium provides resistance to oxidizing chemicals, whereas the high nickel and molybdenum contents supply resistance to nonoxidizing environments.

Send Email Details -

Hot

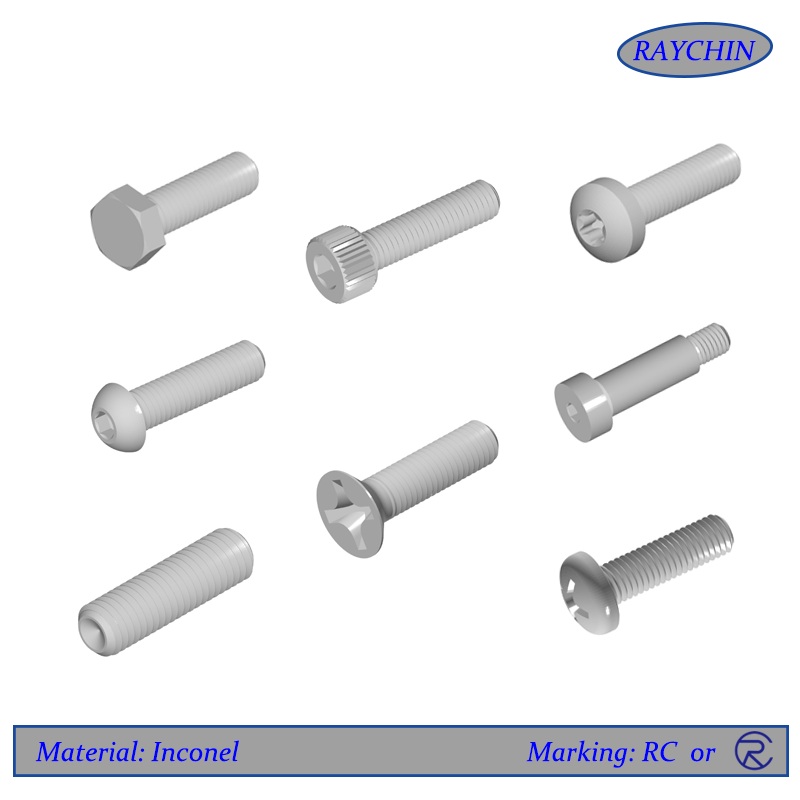

Inconel Screws

Inconel® screws, like Inconel 600, 601,625,686,718 & 725 screws, are a family of nickel-chromium-molybdenum alloys used for their high strength at elevated temperatures and good corrosion resistance. Because of its high thermal stability, Inconel can be used in service temperatures ranging from cryogenic to 2200°F (982°C). The high alloy content of Inconel screws enable it to withstand a wide variety of severe corrosive environments. In mild environments, such as the atmosphere, sea water, neutral salts, and alkaline media, there is almost no attack to Inconel screws. In more severe corrosive environments the combination of nickel and chromium provides resistance to oxidizing chemicals, whereas the high nickel and molybdenum contents supply resistance to nonoxidizing environments.

Send Email Details -

Inconel Washers

Inconel® washers, like Inconel 600, 601,625, 686, 718 & 725 washers, are a family of nickel-chromium-molybdenum alloys used for their high strength at elevated temperatures and good corrosion resistance. Because of its high thermal stability, Inconel can be used in service temperatures ranging from cryogenic to 2200°F (982°C). The high alloy content of Inconel washers enable it to withstand a wide variety of severe corrosive environments. In mild environments, such as the atmosphere, sea water, neutral salts, and alkaline media, there is almost no attack to Inconel washers. In more severe corrosive environments the combination of nickel and chromium provides resistance to oxidizing chemicals, whereas the high nickel and molybdenum contents supply resistance to nonoxidizing environments.

Send Email Details -

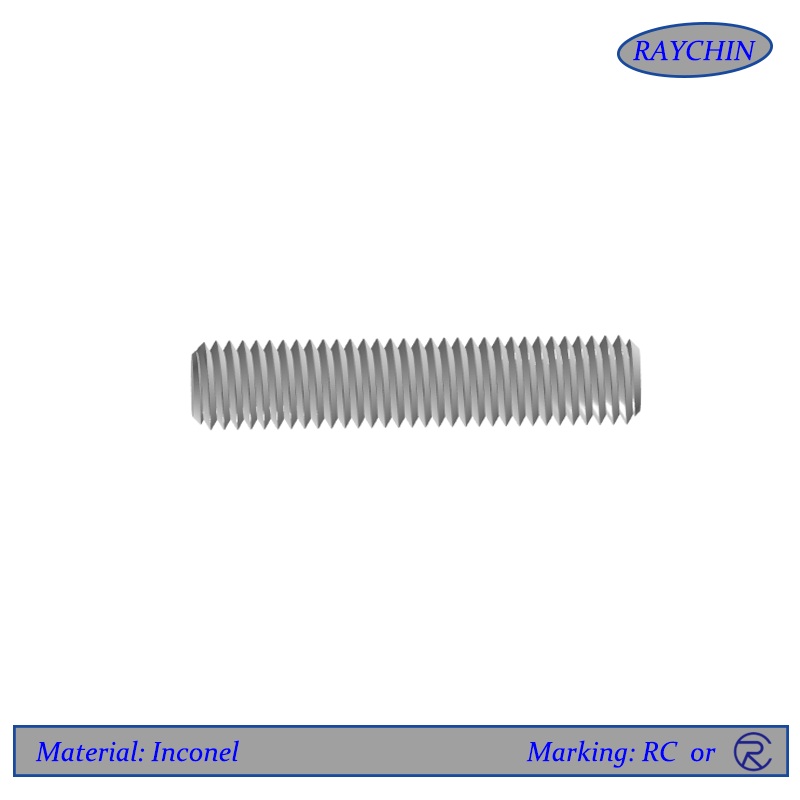

Inconel Threaded Rods

Inconel® threaded rods, like Inconel 600, 601,625, 686, 718 & 725 threaded rods, are a family of nickel-chromium-molybdenum alloys used for their high strength at elevated temperatures and good corrosion resistance. Because of its high thermal stability, Inconel can be used in service temperatures ranging from cryogenic to 2200°F (982°C). The high alloy content of Inconel threaded rods enable it to withstand a wide variety of severe corrosive environments. In mild environments, such as the atmosphere, sea water, neutral salts, and alkaline media, there is almost no attack to Inconel threaded rods. In more severe corrosive environments the combination of nickel and chromium provides resistance to oxidizing chemicals, whereas the high nickel and molybdenum contents supply resistance to nonoxidizing environments.

Send Email Details