-

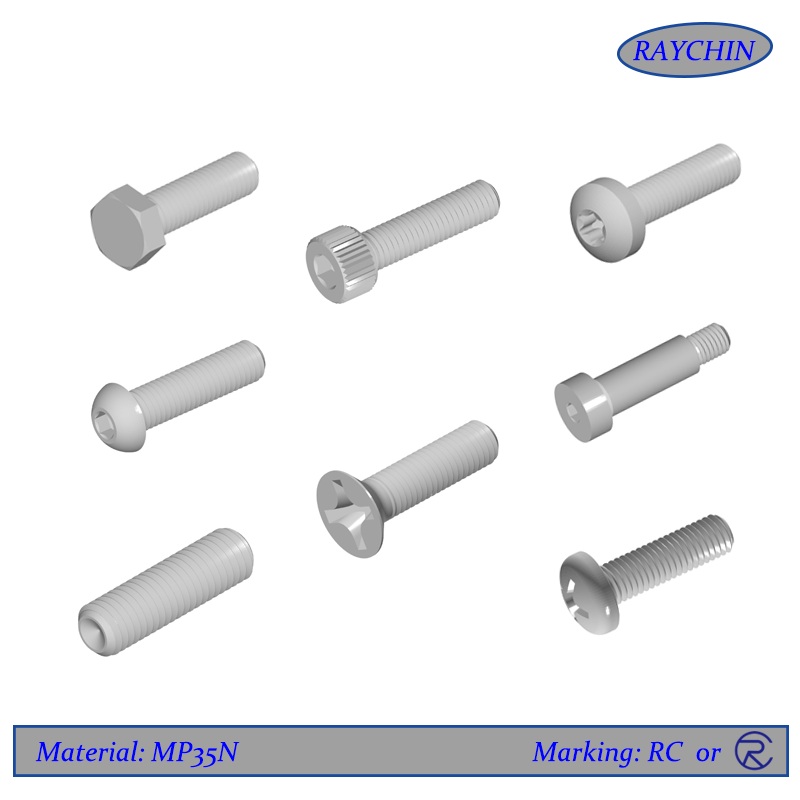

MP35N Fasteners

MP35N (2.4999) fasteners are known for their extraordinary strength and are the strongest fasteners we offer at RAYCHIN. MP35N fasteners owe their extraordinary strength to a unique alloy combination of nickel, cobalt, chrome and molybdenum and have ultimate tensile strengths that range from 227 ksi to 294 ksi (with age hardening).

Send Email Details

Beyond the strength of MP35N fasteners, they are also exhibit good corrosion resistance and can resist most mineral acids, hydrogen sulfide, seawater and salt spray environments.

MP35N fasteners are also resistant to high temperature oxidation and could operate in environments up to 800°F and still maintain much of its strength. -

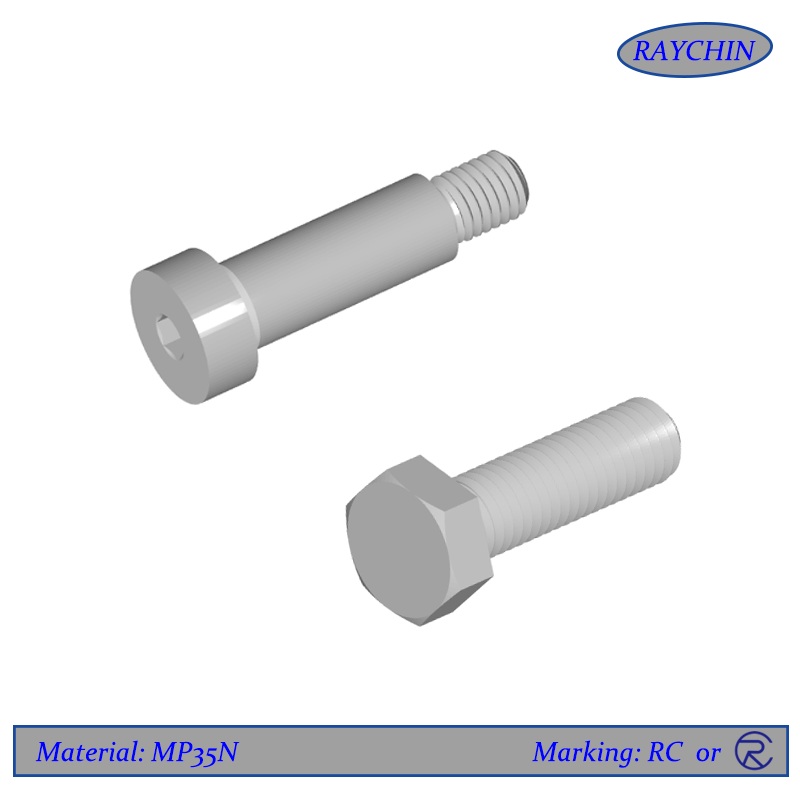

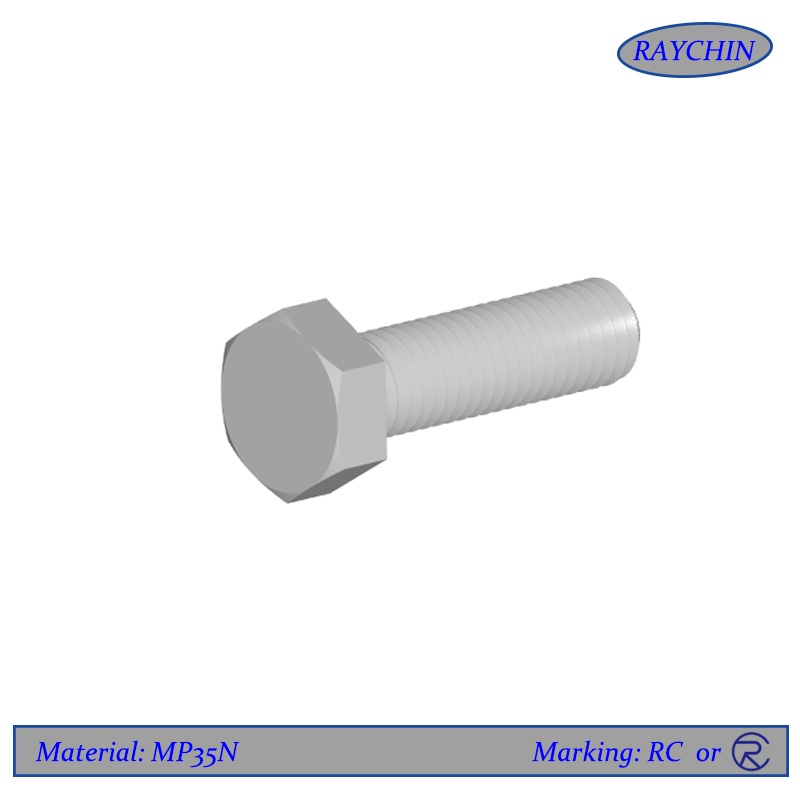

MP35N Bolts

MP35N (2.4999) bolts are known for their extraordinary strength and are the strongest bolts we offer at RAYCHIN. MP35N bolts owe their extraordinary strength to a unique alloy combination of nickel, cobalt, chrome and molybdenum and have ultimate tensile strengths that range from 227 ksi to 294 ksi (with age hardening).

Send Email Details

Beyond the strength of MP35N bolts, they are also exhibit good corrosion resistance and can resist most mineral acids, hydrogen sulfide, seawater and salt spray environments.

MP35N bolts are also resistant to high temperature oxidation and could operate in environments up to 800°F and still maintain much of its strength. -

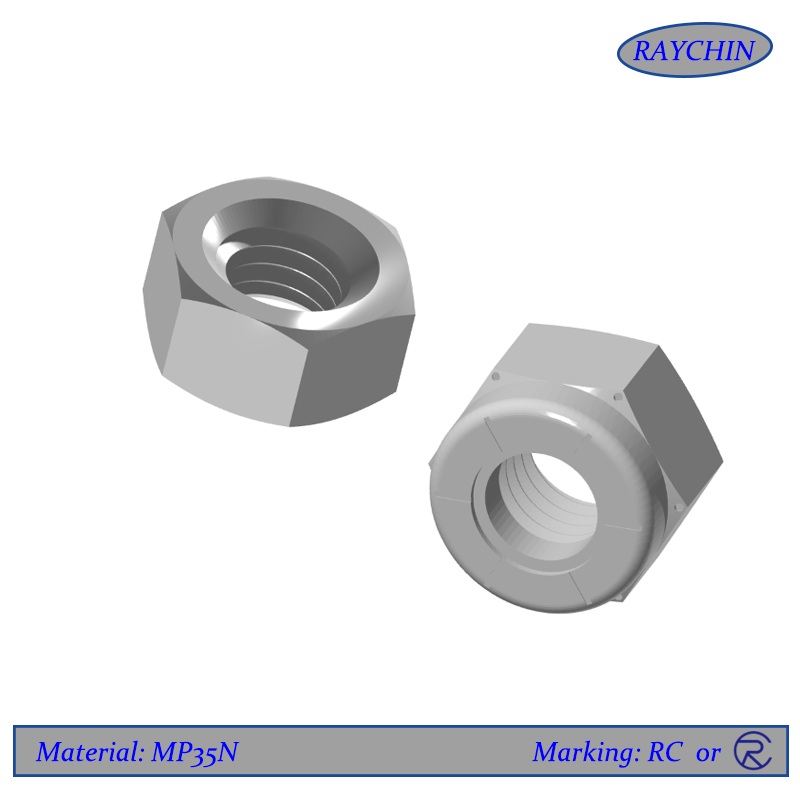

MP35N Nuts

MP35N (2.4999) nuts and lock nuts are known for their extraordinary strength and are the strongest nuts we offer at RAYCHIN. MP35N nuts owe their extraordinary strength to a unique alloy combination of nickel, cobalt, chrome and molybdenum and have ultimate tensile strengths that range from 227 ksi to 294 ksi (with age hardening).

Send Email Details

Beyond the strength of MP35N nuts, they are also exhibit good corrosion resistance and can resist most mineral acids, hydrogen sulfide, seawater and salt spray environments.

MP35N nuts are also resistant to high temperature oxidation and could operate in environments up to 800°F and still maintain much of its strength. -

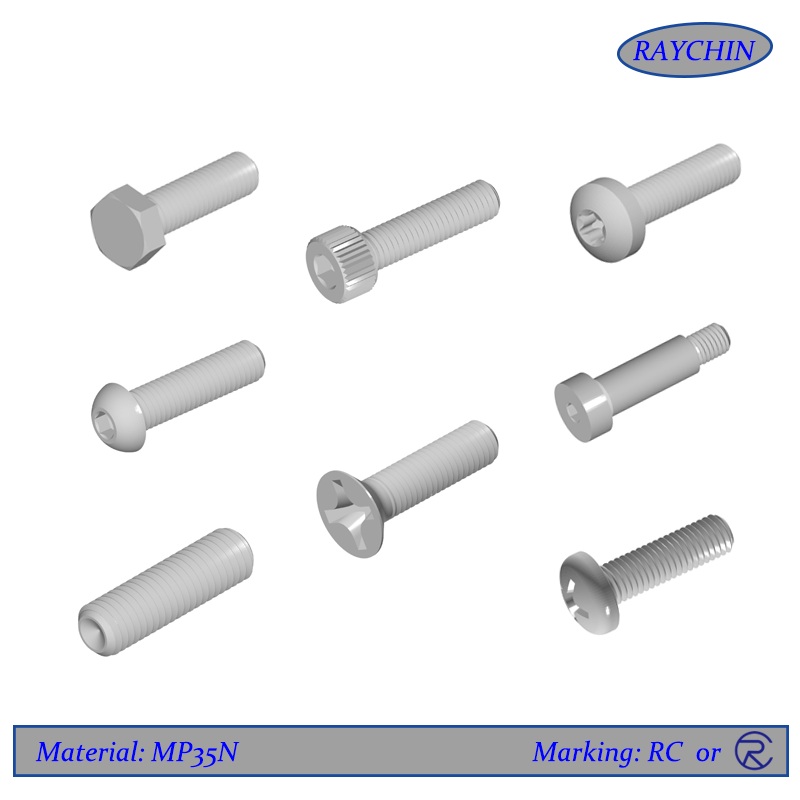

MP35N Screws

MP35N (2.4999) screws are known for their extraordinary strength and are the strongest screws we offer at RAYCHIN. MP35N screws owe their extraordinary strength to a unique alloy combination of nickel, cobalt, chrome and molybdenum and have ultimate tensile strengths that range from 227 ksi to 294 ksi (with age hardening).

Send Email Details

Beyond the strength of MP35N screws, they are also exhibit good corrosion resistance and can resist most mineral acids, hydrogen sulfide, seawater and salt spray environments.

MP35N screws are also resistant to high temperature oxidation and could operate in environments up to 800°F and still maintain much of its strength. -

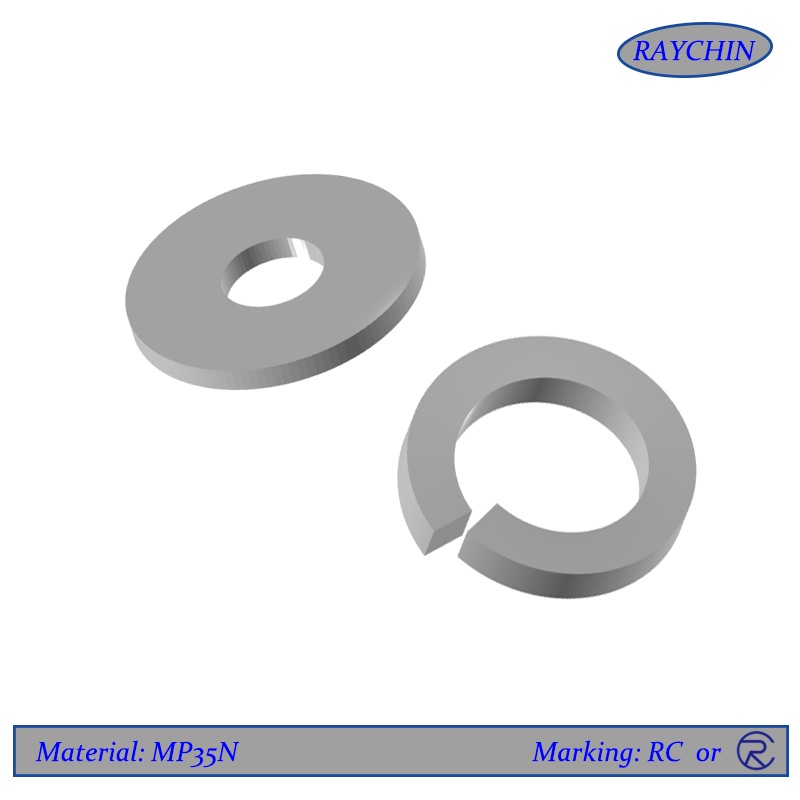

MP35N Washers

MP35N Washers

Send Email Details

MP35N washers are known for their extraordinary strength and are the strongest washers we offer at RAYCHIN. MP35N washers owe their extraordinary strength to a unique alloy combination of nickel, cobalt, chrome and molybdenum and have ultimate tensile strengths that range from 227 ksi to 294 ksi (with age hardening).

Beyond the strength of MP35N washers, they are also exhibit good corrosion resistance and can resist most mineral acids, hydrogen sulfide, seawater and salt spray environments.

MP35N washers are also resistant to high temperature oxidation and could operate in environments up to 800°F and still maintain much of its strength.

Applications where MP35N washers are often found are: aerospace, defense, marine, chemical processing, oil and gas and medical. -

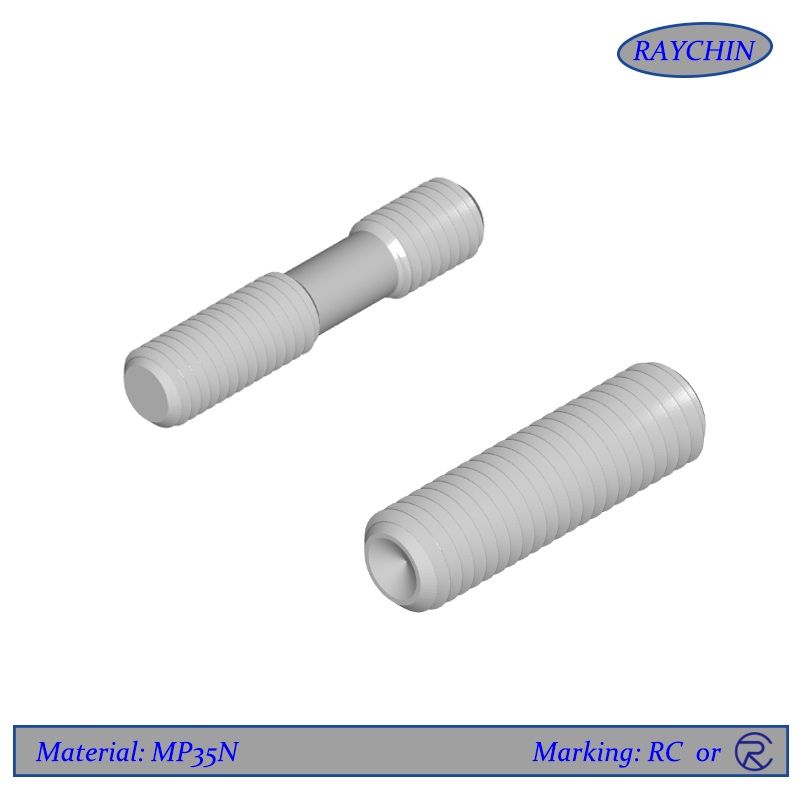

MP35N Studs

MP35N Studs

Send Email Details

MP35N studs are known for their extraordinary strength and are the strongest studs we offer at RAYCHIN. MP35N studs owe their extraordinary strength to a unique alloy combination of nickel, cobalt, chrome and molybdenum and have ultimate tensile strengths that range from 227 ksi to 294 ksi (with age hardening).

Beyond the strength of MP35N studs, they are also exhibit good corrosion resistance and can resist most mineral acids, hydrogen sulfide, seawater and salt spray environments.

MP35N studs are also resistant to high temperature oxidation and could operate in environments up to 800°F and still maintain much of its strength.

Applications where MP35N studs are often found are: aerospace, defense, marine, chemical processing, oil and gas and medical. -

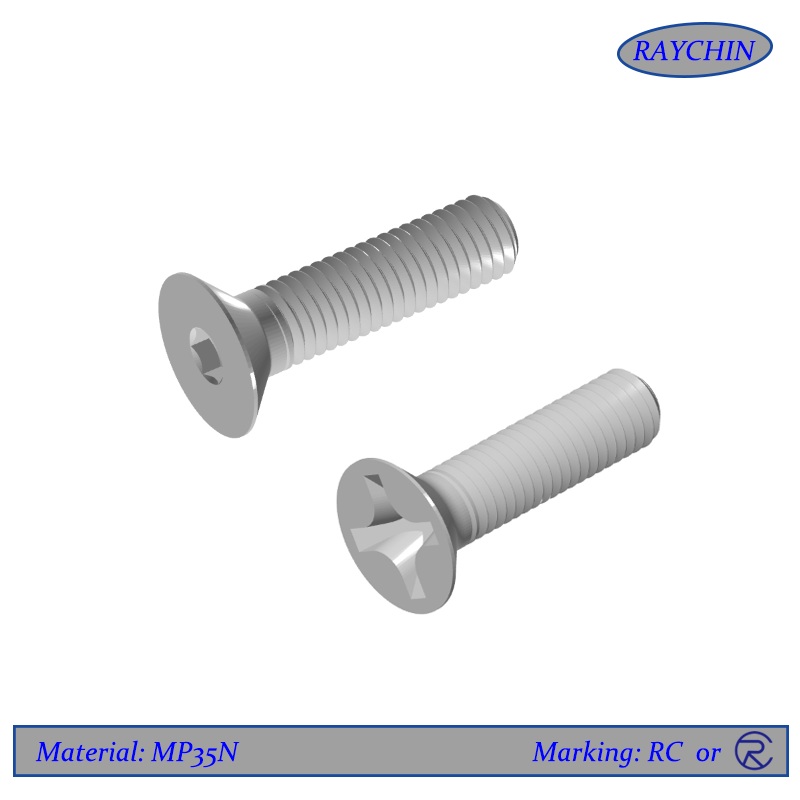

MP35N Flat Head Screws

MP35N flat head screws are known for their extraordinary strength and are the strongest screws we offer at RAYCHIN. MP35N screws owe their extraordinary strength to a unique alloy combination of nickel, cobalt, chrome and molybdenum and have ultimate tensile strengths that range from 227 ksi to 294 ksi (with age hardening).

Send Email Details

Beyond the strength of MP35N flat head screws, they are also exhibit good corrosion resistance and can resist most mineral acids, hydrogen sulfide, seawater and salt spray environments.

MP35N screws are also resistant to high temperature oxidation and could operate in environments up to 800°F and still maintain much of its strength. -

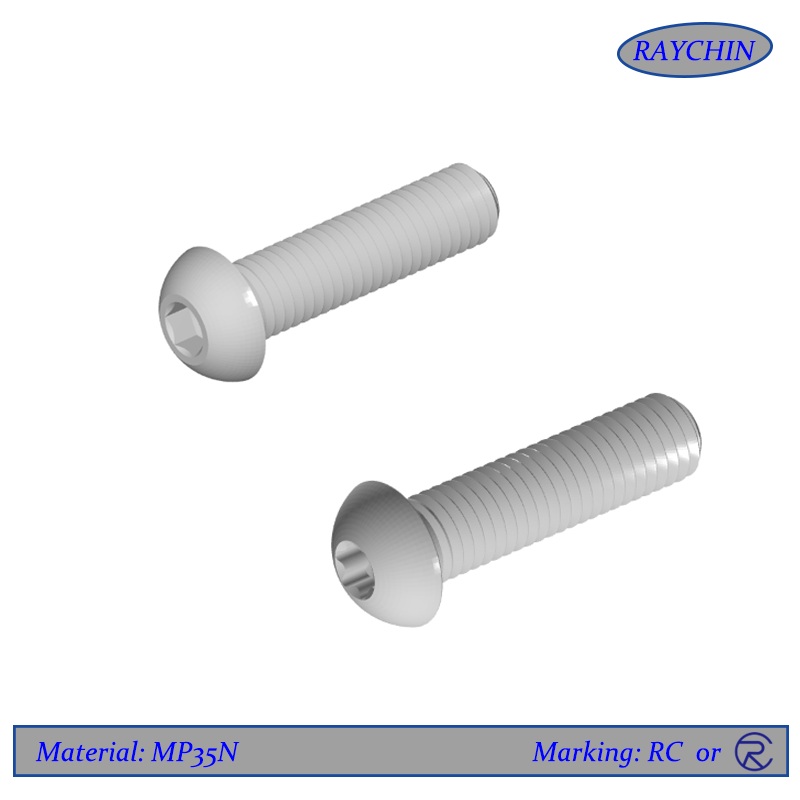

MP35N Button Head Cap Screws

MP35N button head cap screws are known for their extraordinary strength and are the strongest screws we offer at RAYCHIN. MP35N screws owe their extraordinary strength to a unique alloy combination of nickel, cobalt, chrome and molybdenum and have ultimate tensile strengths that range from 227 ksi to 294 ksi (with age hardening).

Send Email Details

Beyond the strength of MP35N button head cap screws, they are also exhibit good corrosion resistance and can resist most mineral acids, hydrogen sulfide, seawater and salt spray environments.

MP35N screws are also resistant to high temperature oxidation and could operate in environments up to 800°F and still maintain much of its strength. -

MP35N Hex Cap Screws

MP35N Hex Head Cap Screws

Send Email Details

MP35N hex head cap screws are known for their extraordinary strength and are the strongest screws we offer at RAYCHIN. MP35N screws owe their extraordinary strength to a unique alloy combination of nickel, cobalt, chrome and molybdenum and have ultimate tensile strengths that range from 227 ksi to 294 ksi (with age hardening).

Beyond the strength of MP35N screws, they are also exhibit good corrosion resistance and can resist most mineral acids, hydrogen sulfide, seawater and salt spray environments. MP35N hex head cap screws are also resistant to high temperature oxidation and could operate in environments up to 800°F and still maintain much of its strength. Applications where MP35N screws are often found are: aerospace, defense, marine, chemical processing, oil and gas and medical.