-

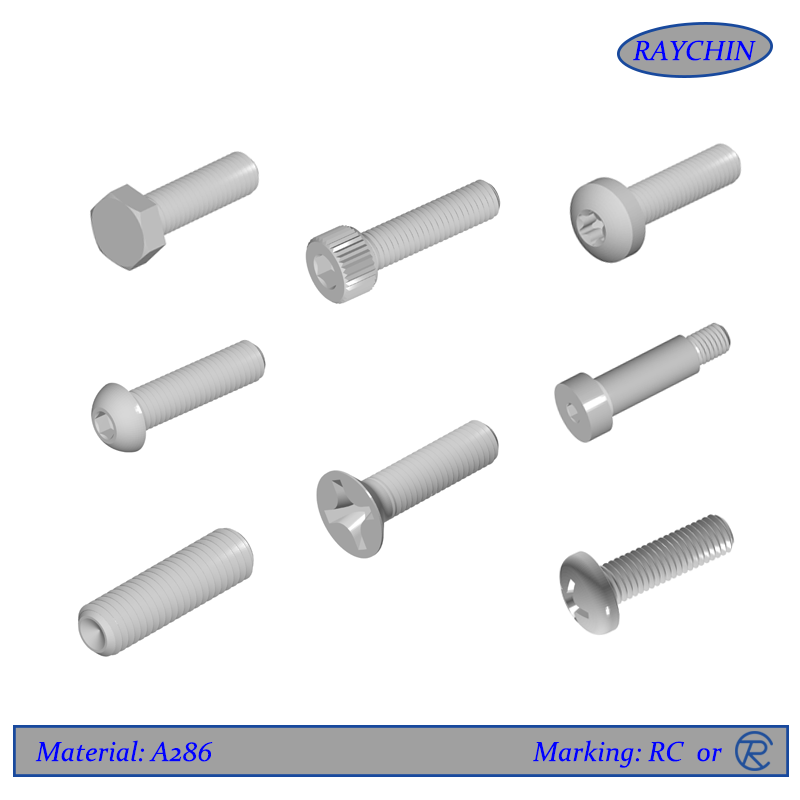

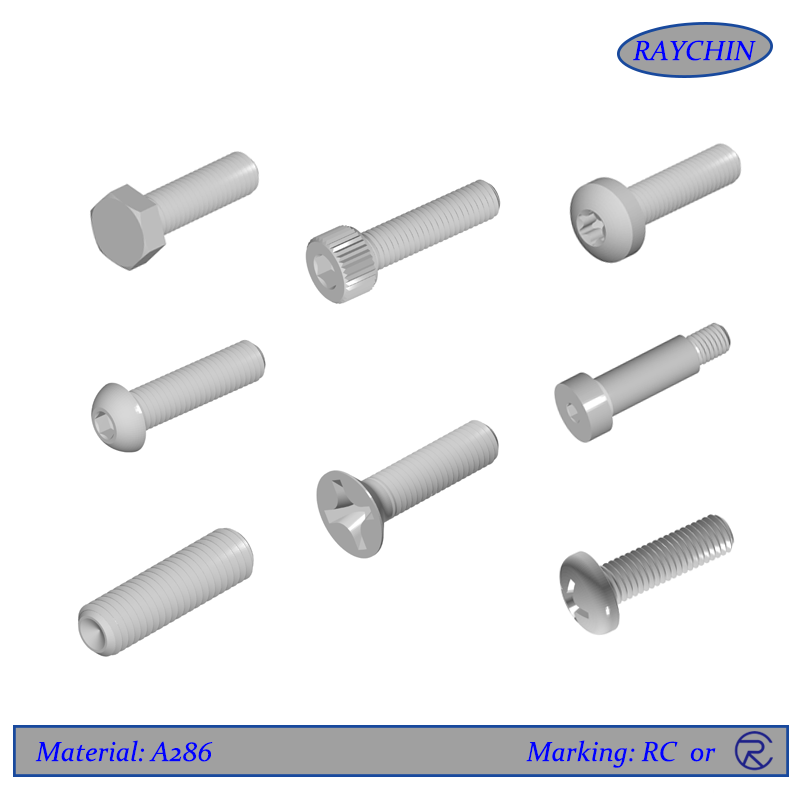

A286 Fasteners

A286 (1.4980) fasteners, also known as Alloy 660 fasteners are stainless steel alloy which contains iron, nickel and chromium. A286 fasteners are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 fasteners provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 fasteners are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. Because A286 fasteners are used in high temperature applications where performance is critical, we can provide fasteners to ASTM A453 Grade 660 in order to ensure accurate standards for tensile and stress rupture properties. -

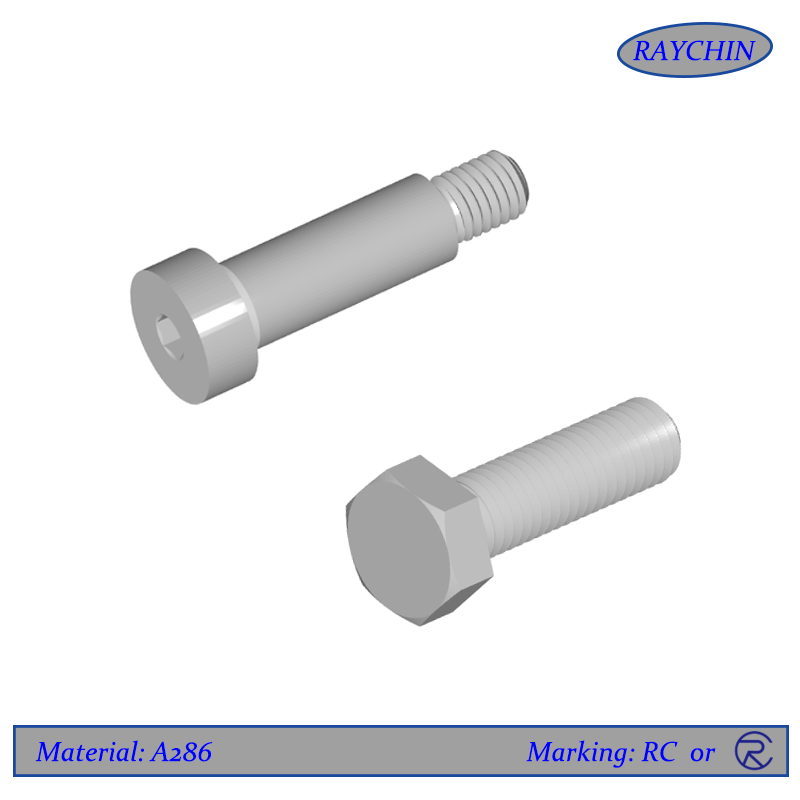

A286 Bolts

A286 (1.4980) bolts, also known as Alloy 660 bolts are stainless steel alloy which contains iron, nickel and chromium. A286 bolts are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 bolts provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 bolts are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. -

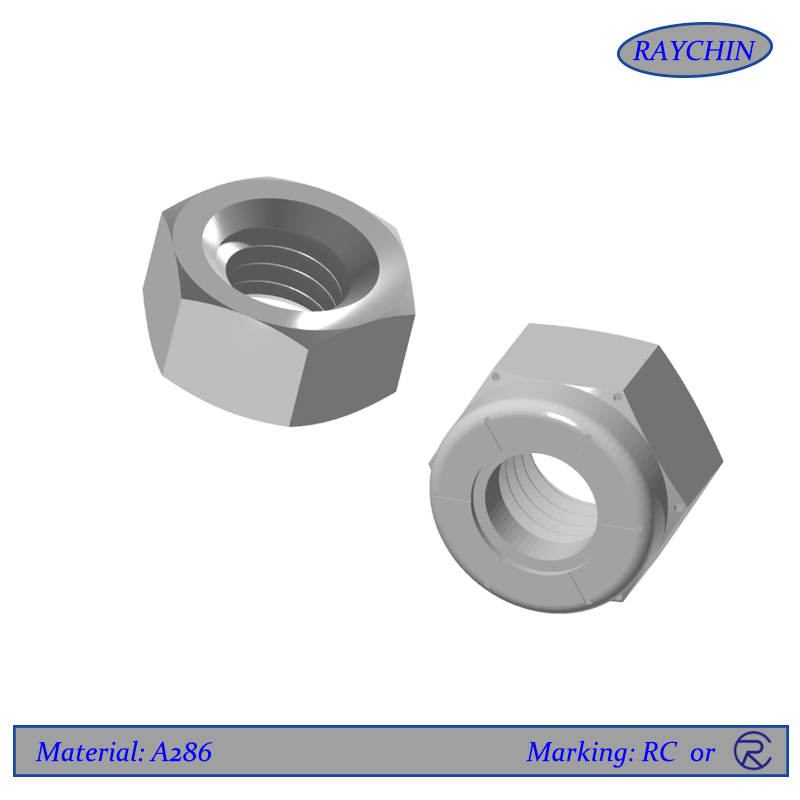

A286 Nuts

A286 (1.4980) nuts, also known as Alloy 660 nuts are stainless steel alloy which contains iron, nickel and chromium. A286 nuts are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 / Alloy 660 nuts provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 nuts are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. -

A286 Screws

A286 (1.4980) screws, also known as Alloy 660 screws are stainless steel alloy which contains iron, nickel and chromium. A286 screws are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 screws provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 screws are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. -

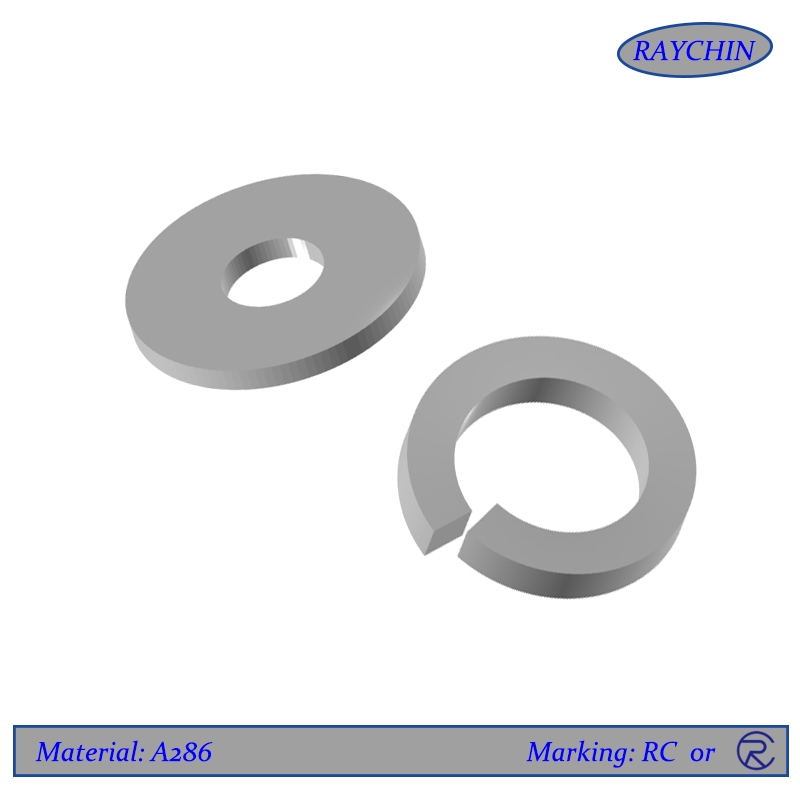

A286 Washers

A286 washers, also known as Alloy 660 washers are stainless steel alloy which contains iron, nickel and chromium. A286 washers are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 / Alloy 660 washers provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 washers are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. -

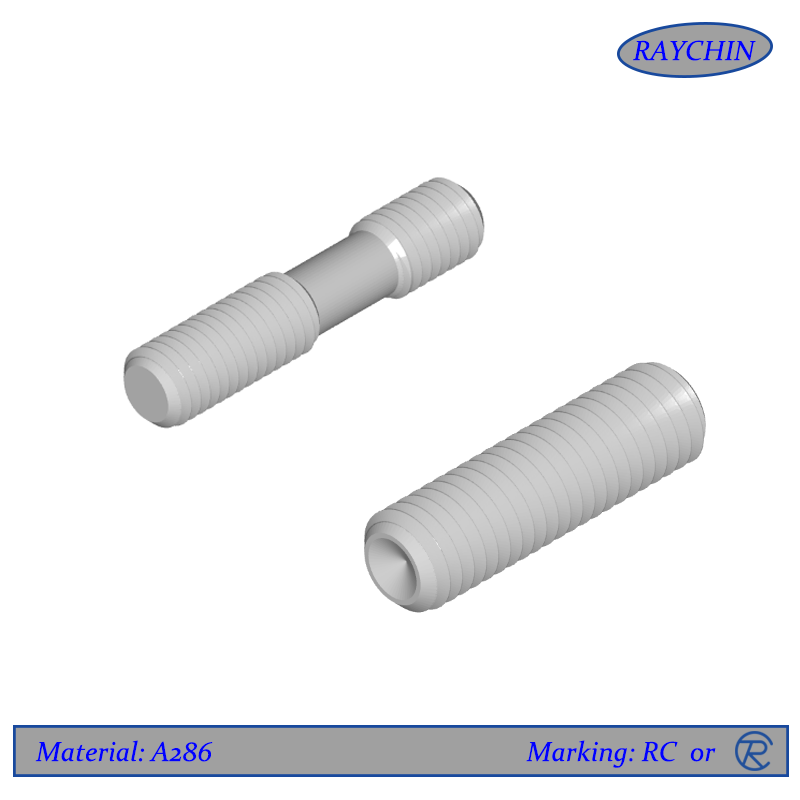

A286 Studs

A286 studs, also known as Alloy 660 studs are stainless steel alloy which contains iron, nickel and chromium. A286 studs are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 / Alloy 660 studs provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 studs are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. -

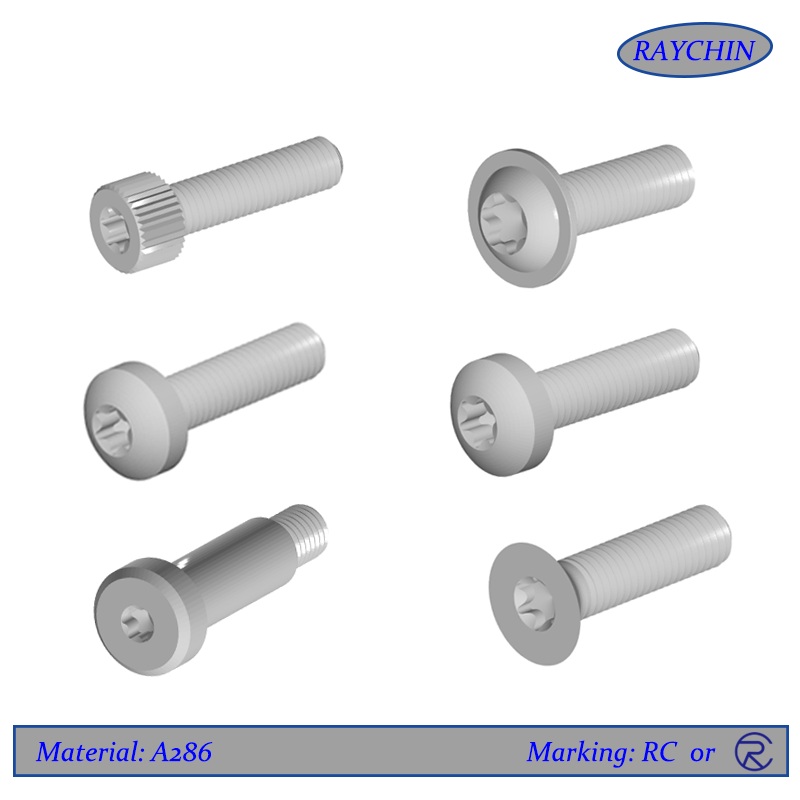

A286 Torx Screws

A286 screws, also known as Alloy 660 screws are stainless steel alloy which contains iron, nickel and chromium. A286 torx screws are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 screws provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 torx screws are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. For the most critical applications, we offer bolts screws per ASTM A453 Grade 660. This ensures tensile and rupture properties. -

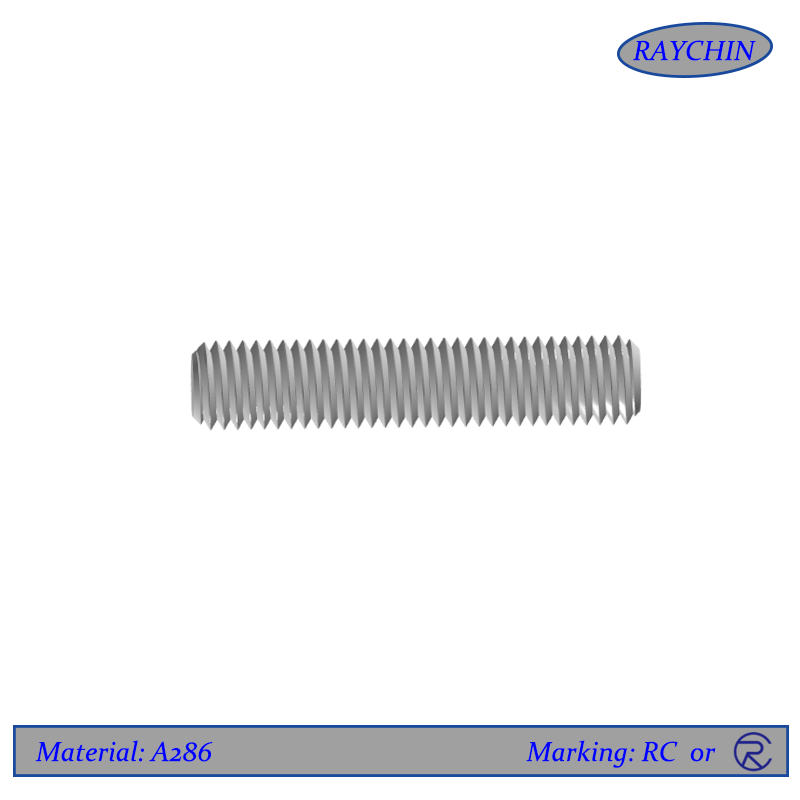

A286 Threaded Rods

A286 threaded rod, also known as Alloy 660 rods are stainless steel alloy which contains iron, nickel and chromium. A286 rods are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 / Alloy 660 fasteners provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 threaded rods are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. -

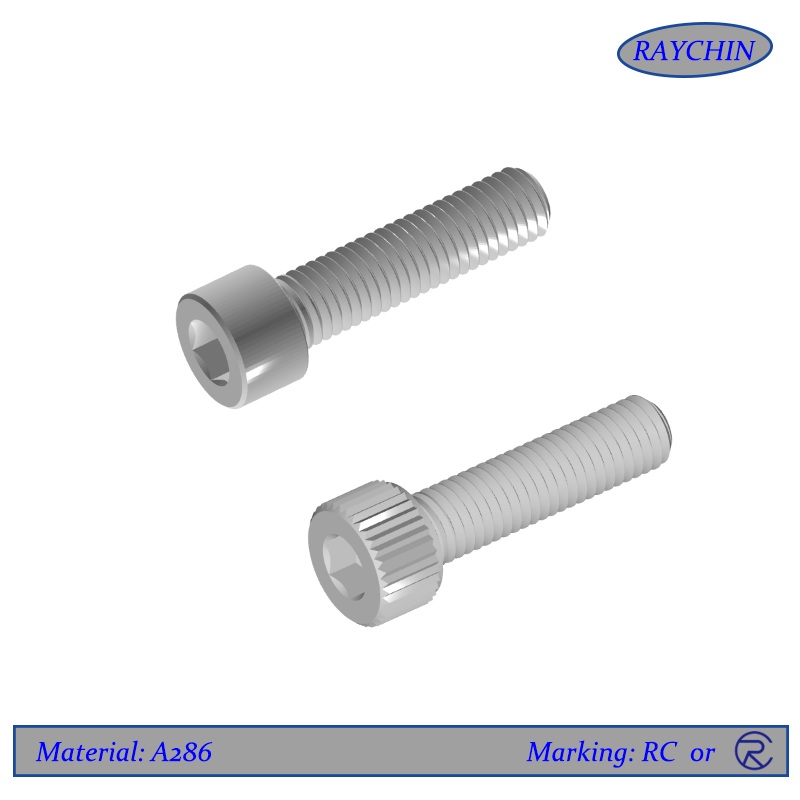

A286 Socket Head Cap Screws

A286 socket head cap screws, also known as Alloy 660 screws are stainless steel alloy which contains iron, nickel and chromium. A286 screws are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 / Alloy 660 screws provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 socket head cap screws are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams.