-

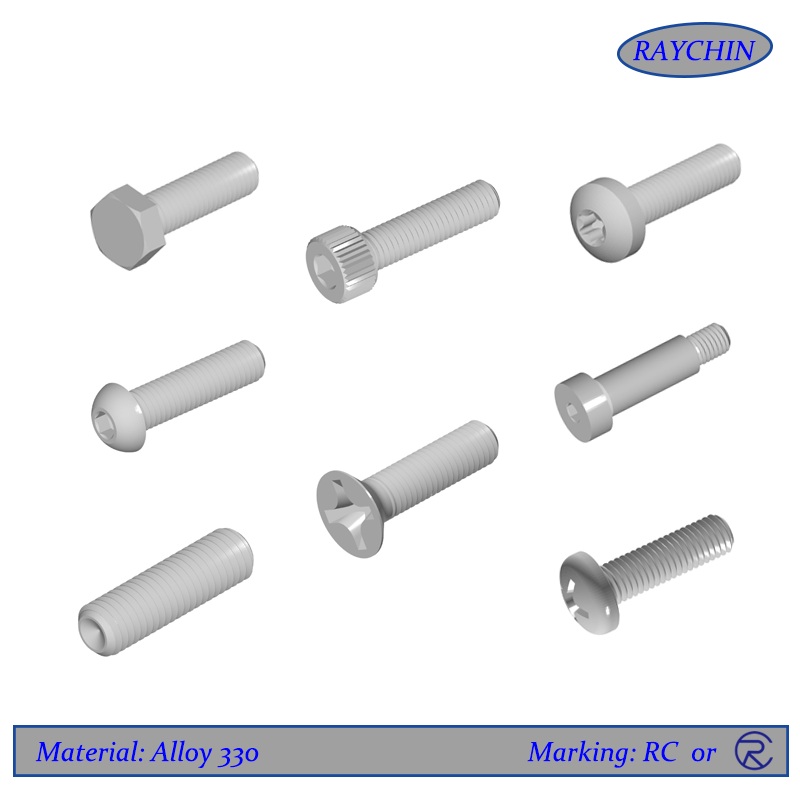

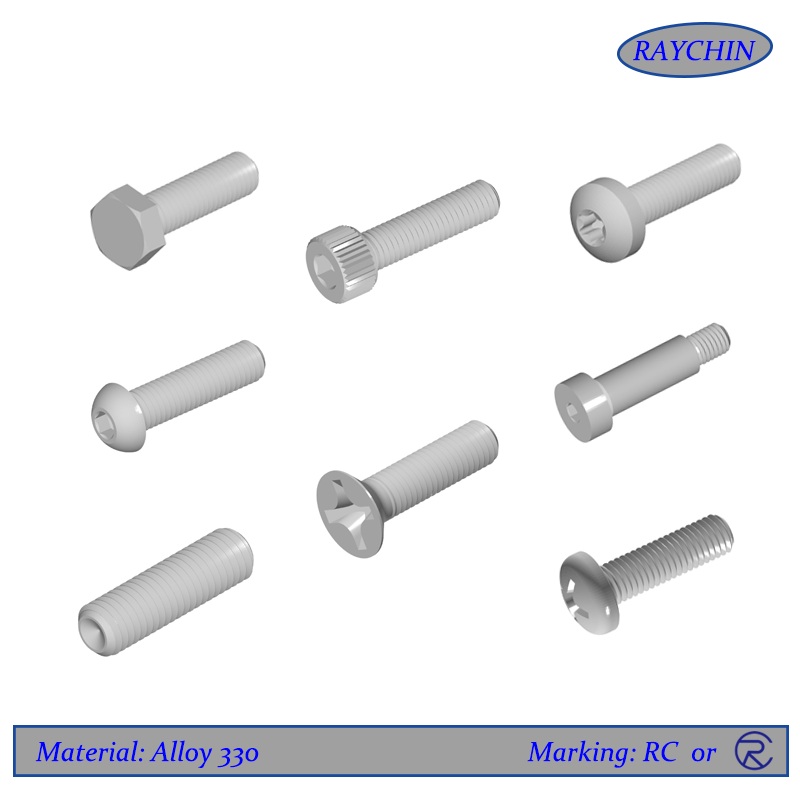

Alloy 330 Fasteners

Alloy 330 (1.4864) fasteners are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic, nickel-chromium-iron-silicon alloy, 330 fasteners also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Send Email Details -

Alloy 330 12 Point Screws

Alloy 330 12 point screws are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic, nickel-chromium-iron-silicon alloy, 330 12 point screws also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Send Email Details -

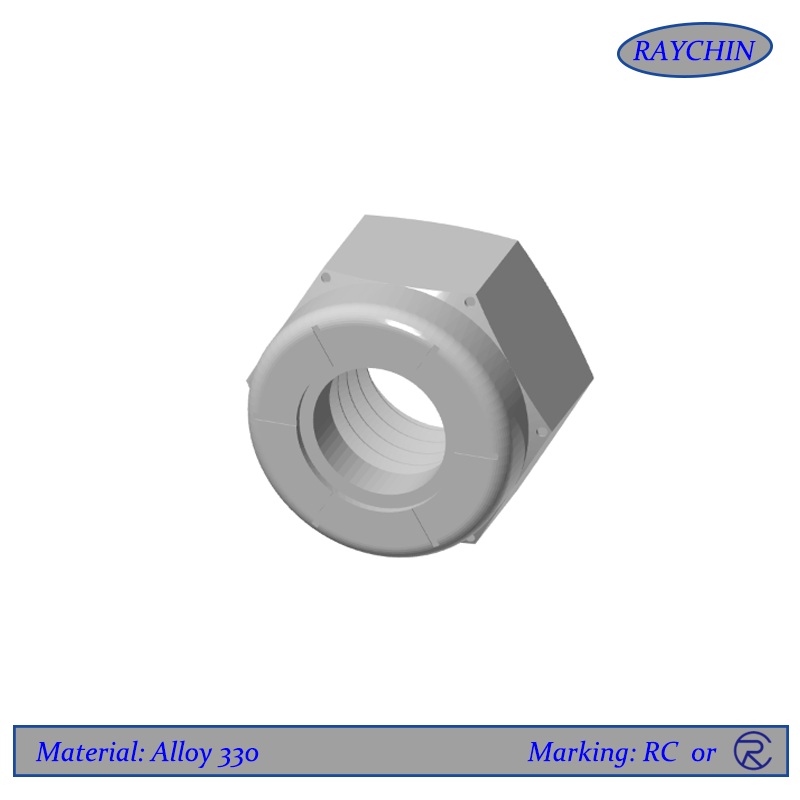

Alloy 330 Lock Nuts

Alloy 330 lock nuts are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic, nickel-chromium-iron-silicon alloy, 330 lock nuts also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Send Email Details -

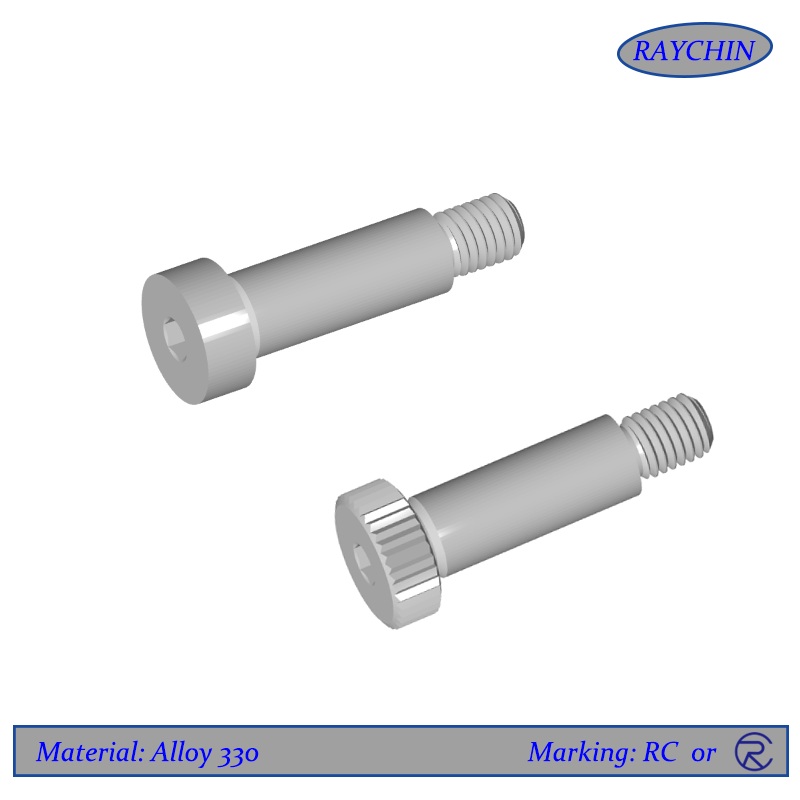

Alloy 330 Shoulder Bolts

Alloy 330 shoulder bolts are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic nickel-chromium-iron-silicon alloy, 330 shoulder bolts also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Send Email Details -

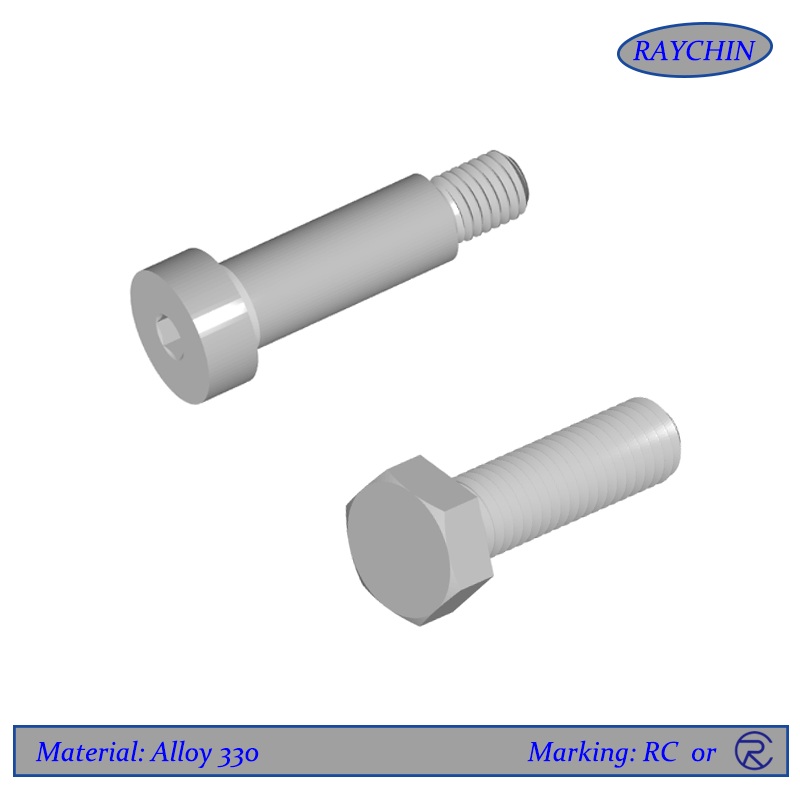

Alloy 330 Bolts

Alloy 330 (1.4864) bolts are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic, nickel-chromium-iron-silicon alloy, 330 bolts also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Send Email Details -

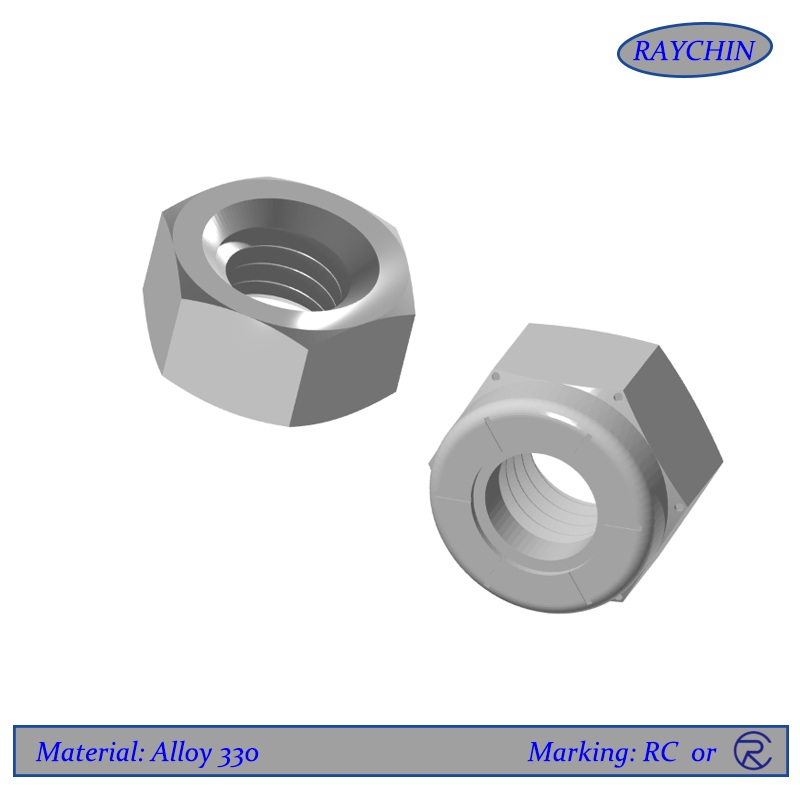

Alloy 330 Nuts

Alloy 330 (1.4864) nuts are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic, nickel-chromium-iron-silicon alloy, 330 nuts also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Send Email Details -

Alloy 330 Screws

Alloy 330 (1.4864) screws are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic, nickel-chromium-iron-silicon alloy, 330 screws also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Send Email Details -

Alloy 330 Washers

Alloy 330 washers are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic nickel-chromium-iron-silicon alloy, 330 washers also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Send Email Details -

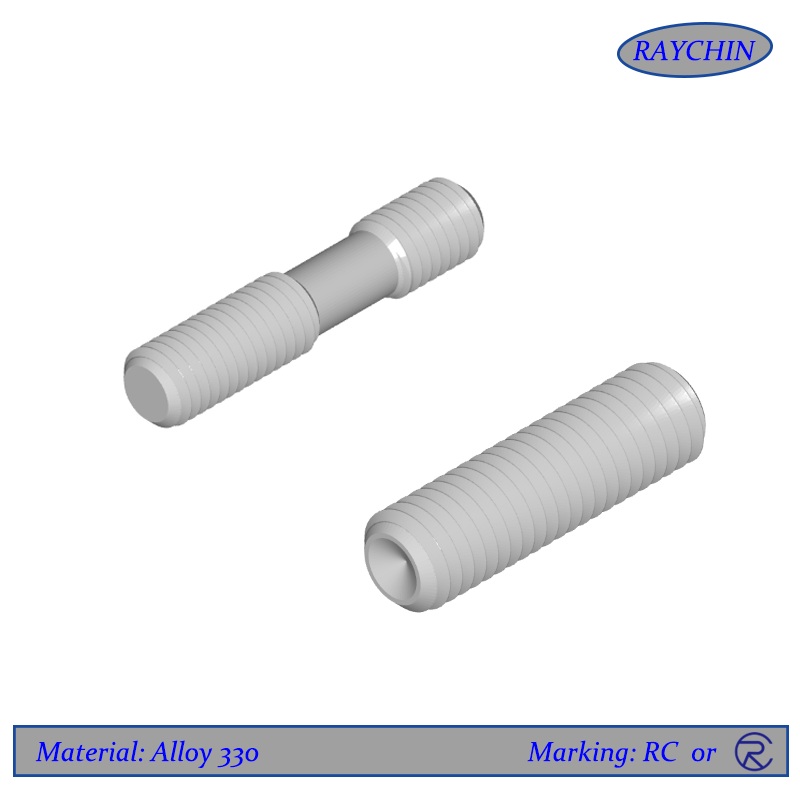

Alloy 330 Studs

Alloy 330 studs are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic, nickel-chromium-iron-silicon alloy, 330 studs also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Send Email Details