-

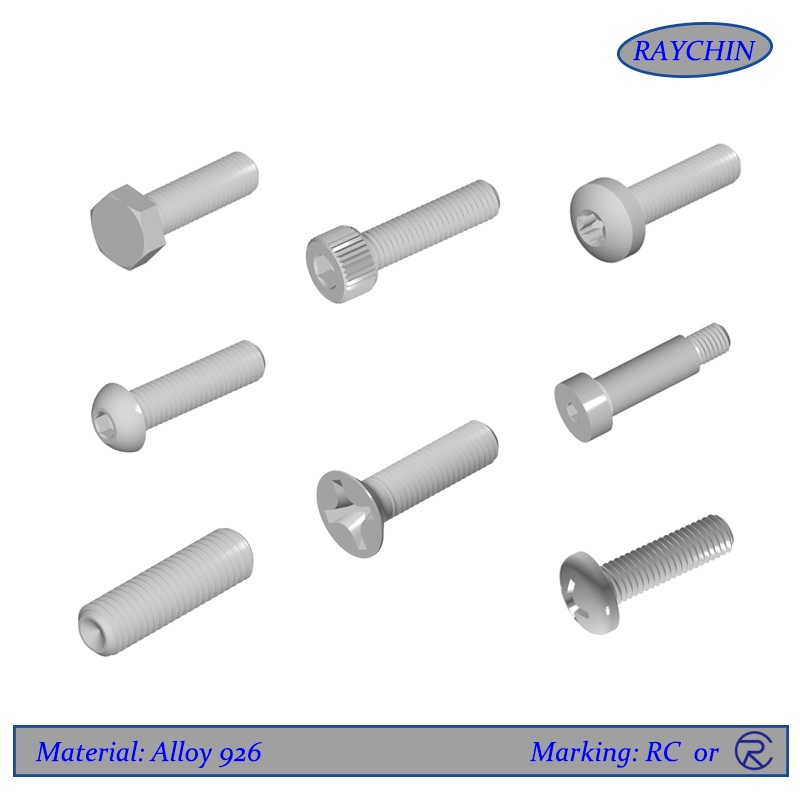

Alloy 926 Fasteners

Alloy 926 (1.4529) screws are the perfect substitute for 316L when higher corrosion resistance is required without additional strength. Alloy 926 fasteners are considered a 6-Moly alloy (6 Mo or 6% Molybdenum) like sister alloys AL6XN and SMO 254. Within the class of stainless steels, these 6 Mo alloys are considered to be very corrosion resistant. Bolts made from Alloy 926 are a super-austenitic molybdenum stainless steel offering corrosion resistance comparable to Super Duplex 2507 but with slightly lower strength and cost. Almost identical in chemistry to 6 Moly alloys AL6XN and SMO 254, Alloy 926 is often chosen for paper plants, desalination and weak acid environements.

Send Email Details

In addition, Alloy 926 fasteners are also similar in composition to 904L, but with increased nitrogen and molybdenum providing Alloy 926 bolts improved general corrosion resistance as well as resistance to pitting and crevice corrosion. Because of Alloy 926 resistance to chloride stress corrosion cracking, it makes 926 fasteners ideal for use in desalination, and pulp and paper plants. This alloy is also good option for diluted sulfuric and phosphorus acid applications.