Alloy 926 Fasteners

Brand RAYCHIN

Product origin China

Delivery time 5-35 DAYS

Alloy 926 (1.4529) screws are the perfect substitute for 316L when higher corrosion resistance is required without additional strength. Alloy 926 fasteners are considered a 6-Moly alloy (6 Mo or 6% Molybdenum) like sister alloys AL6XN and SMO 254. Within the class of stainless steels, these 6 Mo alloys are considered to be very corrosion resistant. Bolts made from Alloy 926 are a super-austenitic molybdenum stainless steel offering corrosion resistance comparable to Super Duplex 2507 but with slightly lower strength and cost. Almost identical in chemistry to 6 Moly alloys AL6XN and SMO 254, Alloy 926 is often chosen for paper plants, desalination and weak acid environements.

In addition, Alloy 926 fasteners are also similar in composition to 904L, but with increased nitrogen and molybdenum providing Alloy 926 bolts improved general corrosion resistance as well as resistance to pitting and crevice corrosion. Because of Alloy 926 resistance to chloride stress corrosion cracking, it makes 926 fasteners ideal for use in desalination, and pulp and paper plants. This alloy is also good option for diluted sulfuric and phosphorus acid applications.

Alloy 926 Fasteners - Screws, Bolts & Nuts

Alloy 926 (1.4529) screws are the perfect substitute for 316L when higher corrosion resistance is required without additional strength. Alloy 926 fasteners are considered a 6-Moly alloy (6 Mo or 6% Molybdenum) like sister alloys AL6XN and SMO 254. Within the class of stainless steels, these 6 Mo alloys are considered to be very corrosion resistant. Bolts made from Alloy 926 are a super-austenitic molybdenum stainless steel offering corrosion resistance comparable to Super Duplex 2507 but with slightly lower strength and cost. Almost identical in chemistry to 6 Moly alloys AL6XN and SMO 254, Alloy 926 is often chosen for paper plants, desalination and weak acid environements.

In addition, Alloy 926 fasteners are also similar in composition to 904L, but with increased nitrogen and molybdenum providing Alloy 926 bolts improved general corrosion resistance as well as resistance to pitting and crevice corrosion. Because of Alloy 926 resistance to chloride stress corrosion cracking, it makes 926 fasteners ideal for use in desalination, and pulp and paper plants. This alloy is also good option for diluted sulfuric and phosphorus acid applications.

A corrosion resistant 6Mo alloy similar to AL6XN and SMO254

· Higher corrosion resistant substitute for 316L

· Corrosion resistance comparable to Super Duplex 2507

· Similar chemistry to AL6XN and SMO 254

· Chemistry and specifications of Alloy 926

· Availability and lead times

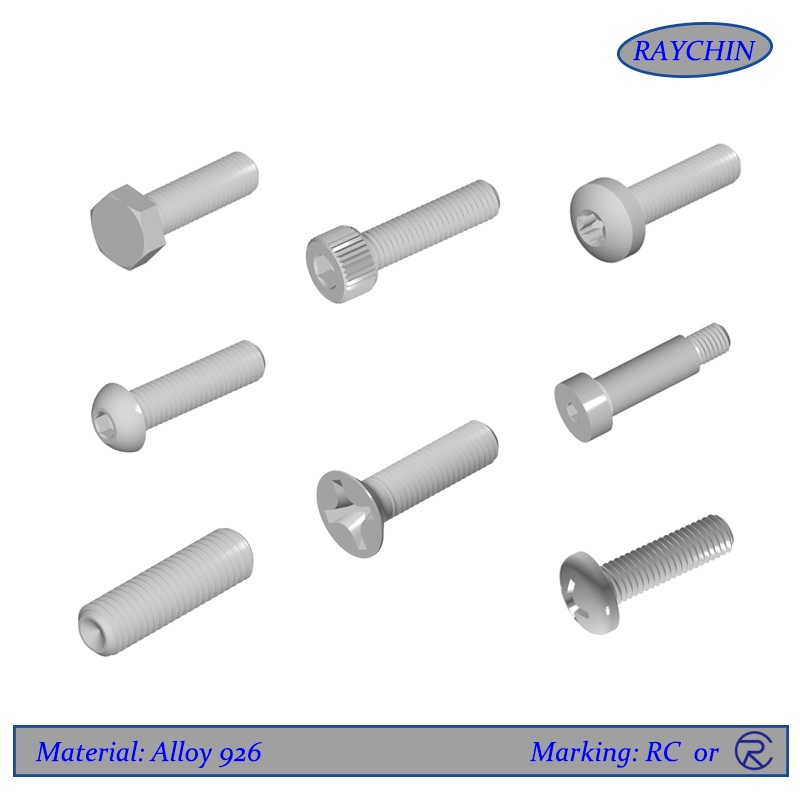

· Alloy 926 fastener styles

Mechnical Properties

• Tensile Strength: 94 ksi

• Yield Strength: 43 ksi

• Elongation: 35%

• Rockwell B Hardness: 86

• Density: 0.29 lb/in³

• Temperature Limits: 750ºF / 400ºC

Alloy 926 Fastener Availability

Availability

Raychin offers Alloy 926 fasteners including many types of screws, nuts, washers and threaded products. Typicially, we have minimum order quantity of 20 pieces for most fasteners. Lead time for production for Alloy 926 fasteners is about 3-4 weeks, depending on the complexity and quantity.

· Diameter sizes: Standard #00 – 4” in diameter / Metric M1.2 – M48

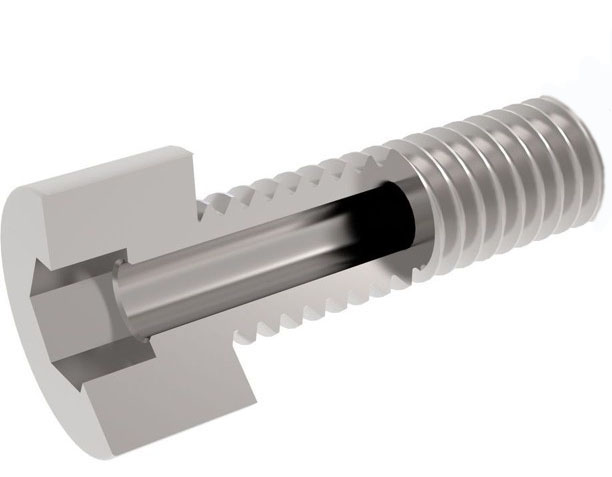

· Threads: UNC, UNF, UNJ, UNR, Rolled,and Cut

· Custom to print available.

· ASTM, ASME, and Domestic available

Expediting Options

We understand that many applications require a fast lead time. If you need expedited shipping, please let us know when submitting a quote so that we can do our best to accommodate your specific needs.

Alloy 926 Fastener Styles

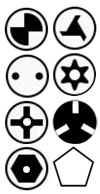

| Alloy 926 Screws | 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Head Cap Screws, Pan Head Screws, Security Screws, Set Screws, Socket Head Cap Screws, Vented Screws |

|

| Alloy 926 Bolts | Hex Head Bolts, Shoulder Bolts | • DIN 931 • DIN 933 • ISO 4014 • ISO 4017 • ISO 7370 |

| Alloy 926 Nuts | Hex Nuts, Lock Nuts | • DIN 439 / ISO 4035 • DIN 934 / ISO 4032 • DIN 985 / ISO 7040 • DIN 986 • DIN 980 / ISO 7042 / ISO 19513 • DIN 6923 / ISO 4161 |

| Alloy 926 Threaded Products | Studs, Threaded Rods | • DIN 975 • DIN 976 |

| Alloy 926 Washers | Flat Washers, Lock Washers | • DIN 125 / ISO 7089 / ISO 7090 • DIN 126 / ISO 7091 • DIN 127 / ISO 7090 • DIN 9021 / ISO 7093 |

Alloy 926 (1.4529) Chemistry & Specifications

Alloy 926 (1.4529) Chemistry

Alloy 926 | Fe | Ni | Cr | Mo | Mn | Cu | Si | N | P | C | S |

Min% | - | 24.00 | 19.00 | 6.00 | 0.50 | 0.15 | |||||

Max % | Bal | 26.00 | 21.00 | 7.00 | 2.00 | 1.50 | 0.50 | 0.25 | 0.03 | 0.020 | 0.01 |