-

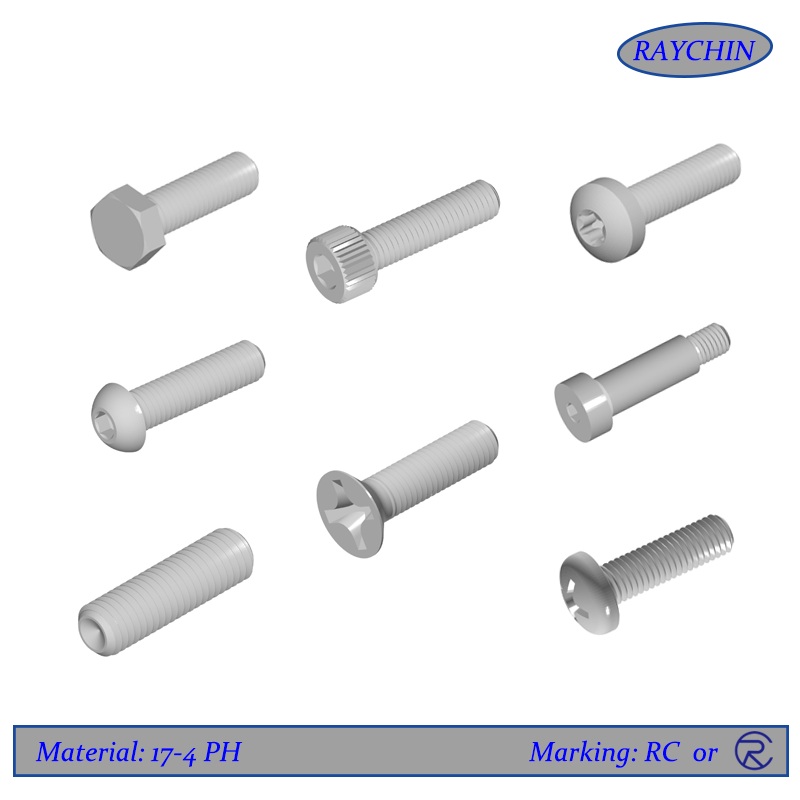

17-4 PH Screws

17-4 PH screws are made from a precipitation hardened stainless steel most known for its exceptional strength and its ability to maintain its mechanical properties to 600°F. Compared to 316 stainless steel, 17-4 PH screws yield strength is up over 4 times greater. When compared to Duplex 2205 screws, the yield strength of 17-4 PH can be up to 2-½ times greater.

Send Email Details

17-4 screws are available in 8 different aged (precipitation hardened) conditions offering a variety of mechanical properties (see below). In addition, RAYCHIN also provide screws per ASTM F593 Grade 630 to ensure the proper tensile and yield strengths for sensitive applications. -

Nitronic Screws

Nitronic is a high strength austenitic steel alloy that was designed for high temperature use. It offers good high temperature properties as well as good low-temperature impact resistance. In addition, Nitronic bolts also offer nearly double the yield strength of 300 series stainless steel. Nitronic fasteners are available in two alloy variations, Nitronic 50 and Nitronic 60, each offering different niche capabilities.

Send Email Details -

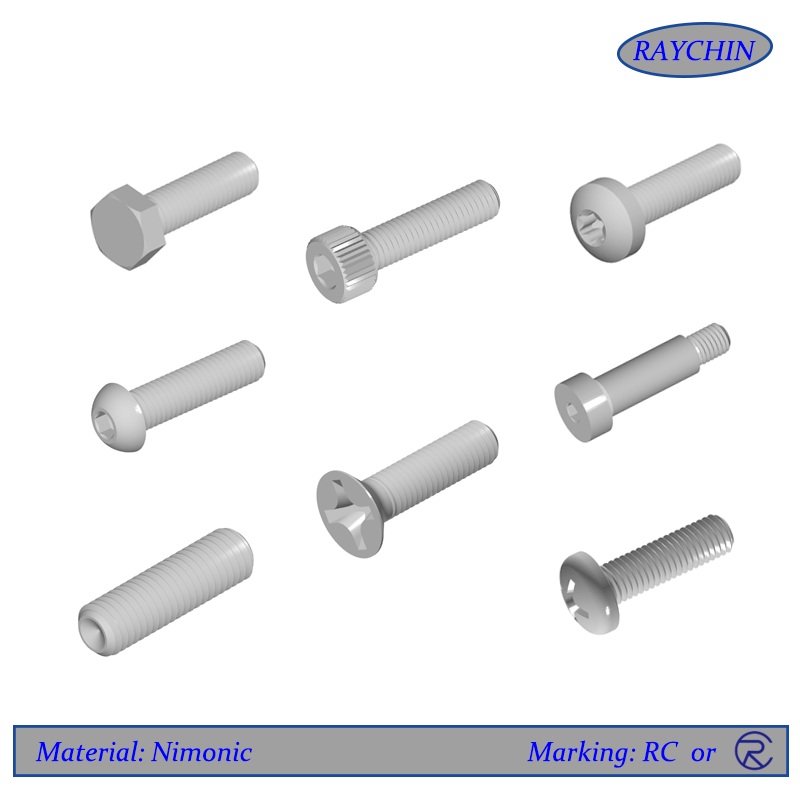

Nimonic Screws

Nitronic is a high strength austenitic steel alloy that was designed for high temperature use. It offers good high temperature properties as well as good low-temperature impact resistance. In addition, Nitronic bolts also offer nearly double the yield strength of 300 series stainless steel. Nitronic fasteners are available in two alloy variations, Nitronic 50 and Nitronic 60, each offering different niche capabilities.

Send Email Details -

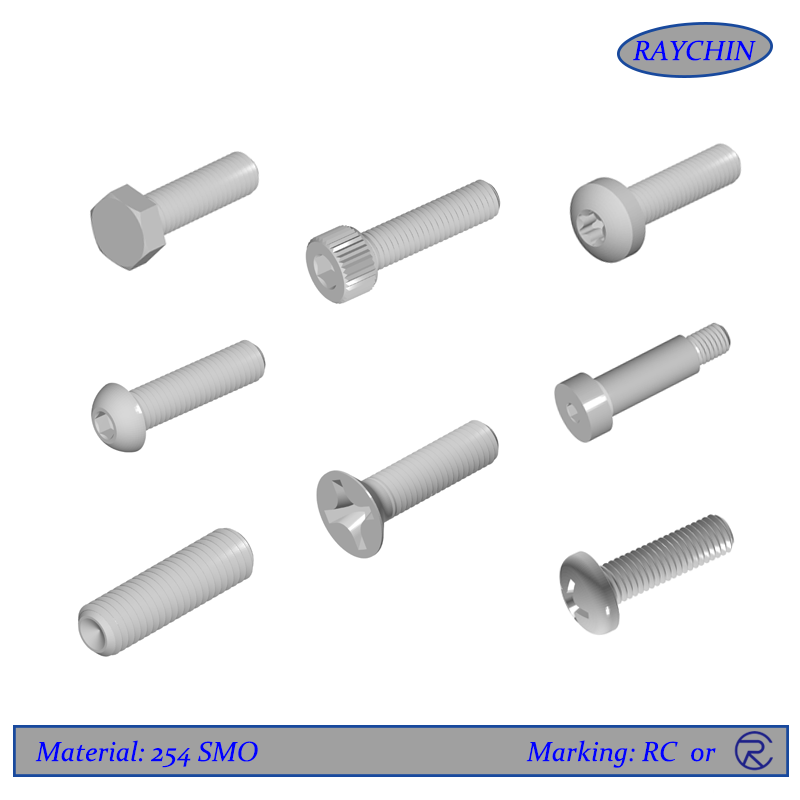

254 SMO Screws

12 Point Screws254 SMO 12 point screws are ideal when you need higher torque than socket head cap screws offer. These screws are available in 1/4" diameter or larger. The only drawback is 12 point screws are less economical and require a higher minimum quantity due to the complexity of production.• IFI-115

Send Email Details

• MIL SPEC

• DIN 34822

• DIN 34821

Button Head Cap ScrewsFor applications that require a wide clamping area and low profile fastener 254 SMO button head cap screws are a good choice. Button head screws are also used for fastening a material that is too thin to counter bore.• ASME B18.3

• ASME 18.3.4M

• DIN 7380 / ISO 7380

Flat Head Screws254 SMO flat head screws come standard with an 82° countersink angle. Other angles ranging from 60° -120° can also be made upon request. 254 SMO flat heads can be made with slotted or socket drivers. Phillips, torx and tamperproof drivers are also available depending on size, quantity and material.• ASME B18.3

• ASME B18.3.6

• DIN 963 / ISO 2009

• DIN 965 / ISO 7046

• DIN 7991 / ISO 10642

Hex Head Cap Screws254 SMO hex head cap screws are one of the most commonly used styles. They feature an added washer face that hex head bolt do not have. This washer face provides tighter dimensional tolerances. 254 SMO hex head cap screws provide high clamping force and easy access.• ASME B18.6.3

• DIN 931 / ISO 4014

• DIN 933 / ISO 4017

• DIN 961 / ISO 8676

Pan Head ScrewsPan head screws have a rounded head and most commonly have a slotted driver. 254 SMO pan heads are best for small diameter and low torque applications.• ASME B18.6.3

• DIN 7985

• DIN 921

• DIN 85 / ISO 1580

• DIN 84 / ISO 1207

(cheese head)

• DIN 966 / ISO 7047

(raised counter sunk) -

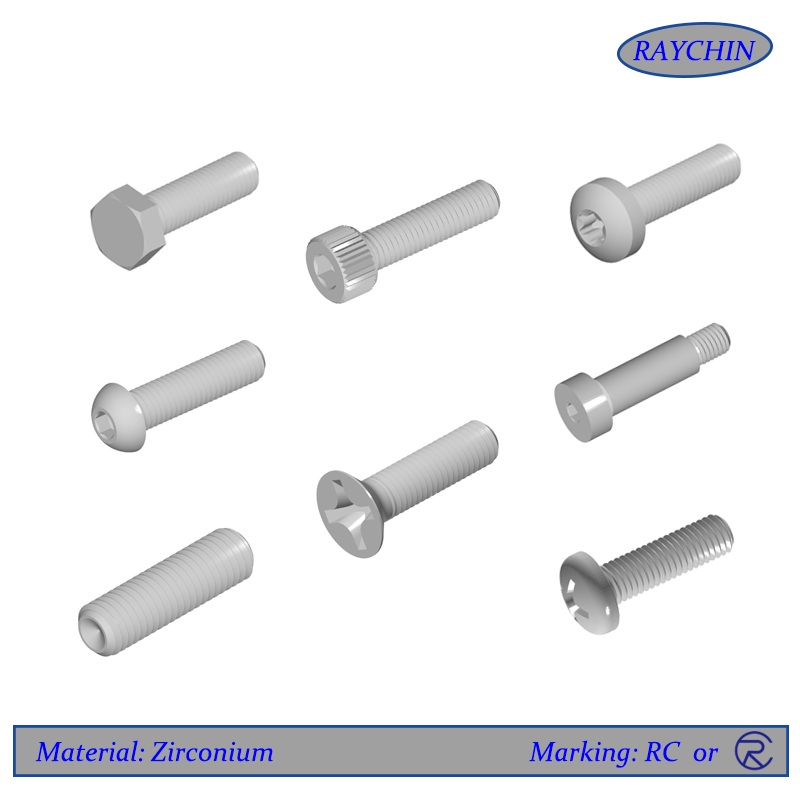

Zirconium Screws

Commercially pure zirconium screws, also known as zirconium 702, are most well-known for their superior corrosion resistance in some of the harshest environments that include:

Send Email Details

• Hydrochloric Acid• Sulfuric Acid• Formic Acid• Nitric Acid • Acetic Acid

It is also a metal that offers industry unique properties. It does not absorb neutrons, making it ideal for use in nuclear power and at low temperatures it is superconductive, making it ideal for super magnets. -

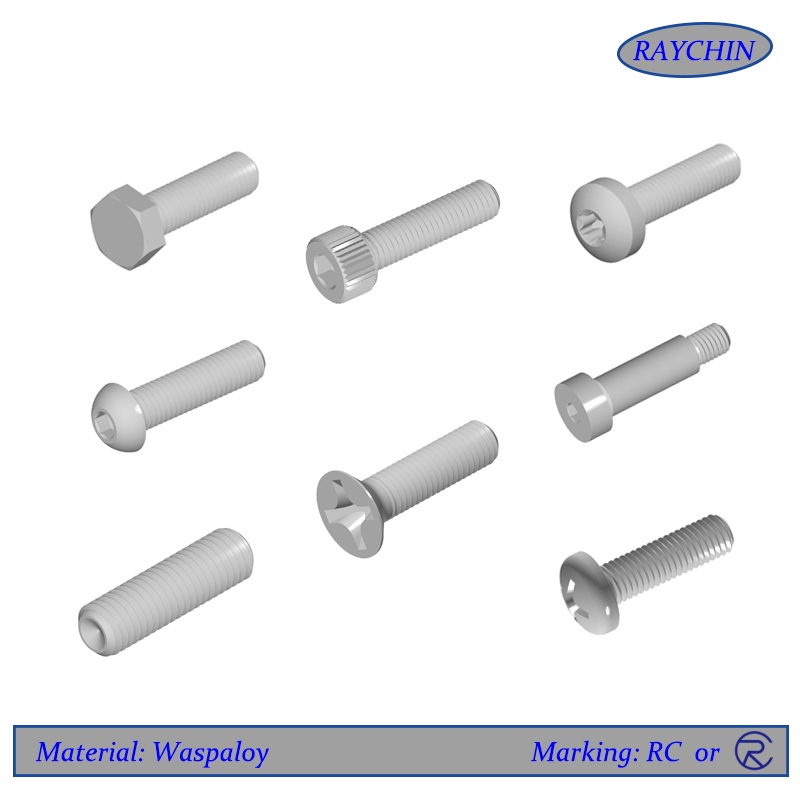

Waspaloy Screws

Waspaloy (2.4654) screws are known for their superb high strength at elevated temperatures. Waspaloy is a high performance nickel alloy combined with cobalt, chrome and molybdenum to create it’s unique combination of strength and high temperature stability.

Send Email Details

Similar to that of Inconel 718 screws, Waspaloy screws exceed the strength and stability of Inconel 718 at elevated temperatures beyond 1400°F. In addition, the oxidation resistance of Waspaloy screws make it an ideal materials for high temperature applications like gas turbines engines, and a variety of other aerospace components. -

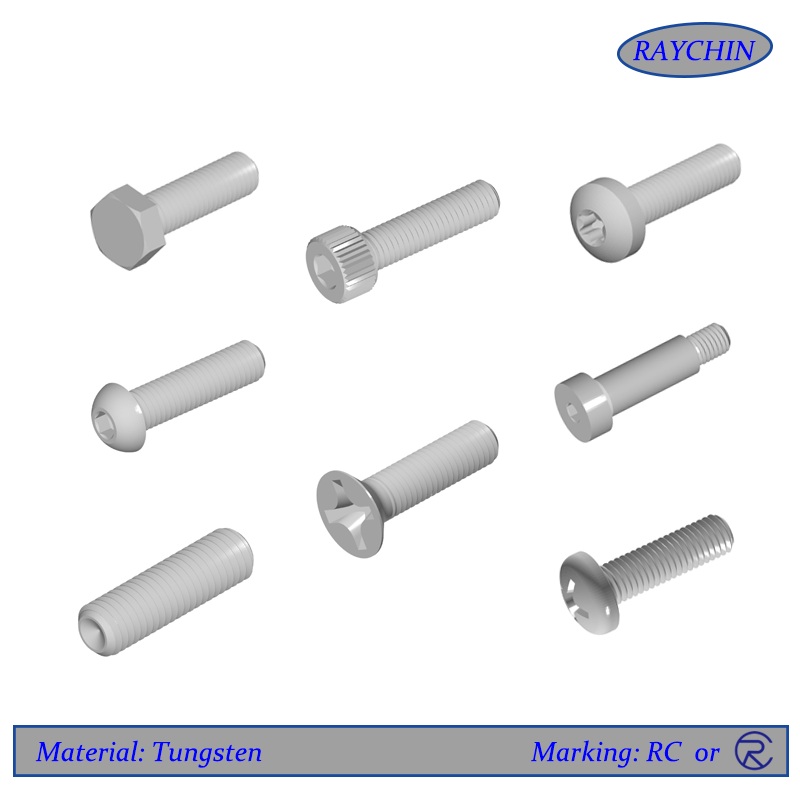

Tungsten Screws

Tungsten screws are known for their extreme high density; because of this unique attribute, they are often used for balancing rotating parts. Tungsten’s high mass also makes these screws radiopaque. This allows tungsten screws to block radiation and show up well on x-rays – even better than lead. Another unique attribute of tungsten is its extrmely high melting point of 3420°C. The high temperature stability of tungsten screws make them ideal for some of the hottest vacuum furnace environments.Beyond their high mass and temperature stability, tungsten fasteners are also very corrosion resistant.

Send Email Details

Tungsten fasteners are usually made from tungsten alloys per ASTM B777, and range from 90% to 97% pure tungsten, alloyed with nickel and copper or nickel and iron. -

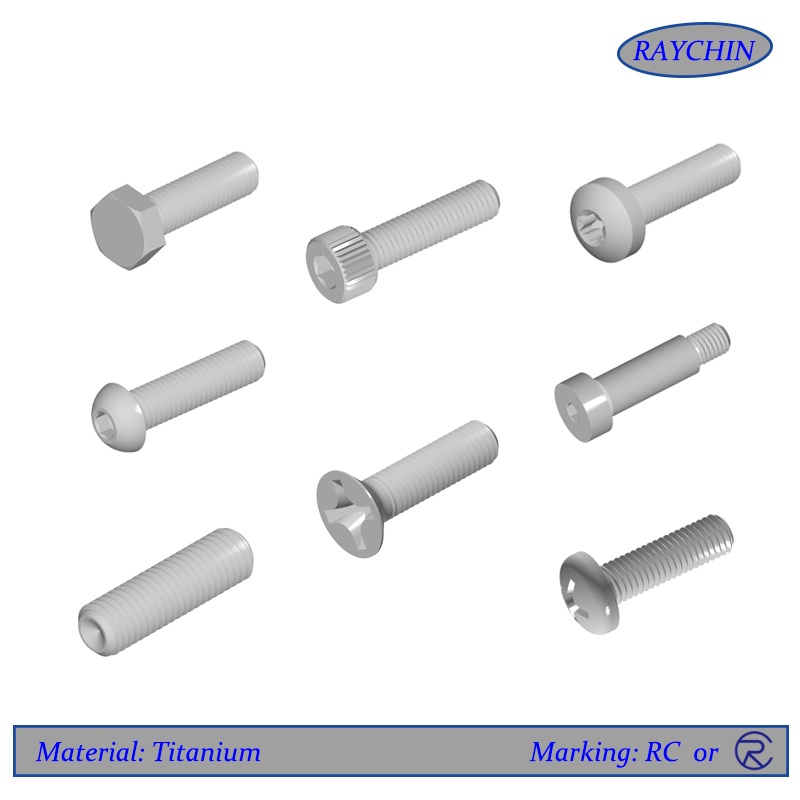

Titanium Screws

Titanium fasteners are best known for being strong, lightweight, and corrosion resistant. They are critical to many industries including chlor alkali, marine, off-shore oil & gas, desalination, medical, and pulp and paper. Grade 2 and 5 are the most commonly used grades of titanium screws:

Send Email Details

• Grade 2 (UNS R50400 / 3.7035) :Commercially pure titanium and the most common grade for screws.

• Grade 5 (UNS R56400 / 3.7165): Superior strength-to-weight ratio for a unique combination of corrosion and high strength. -

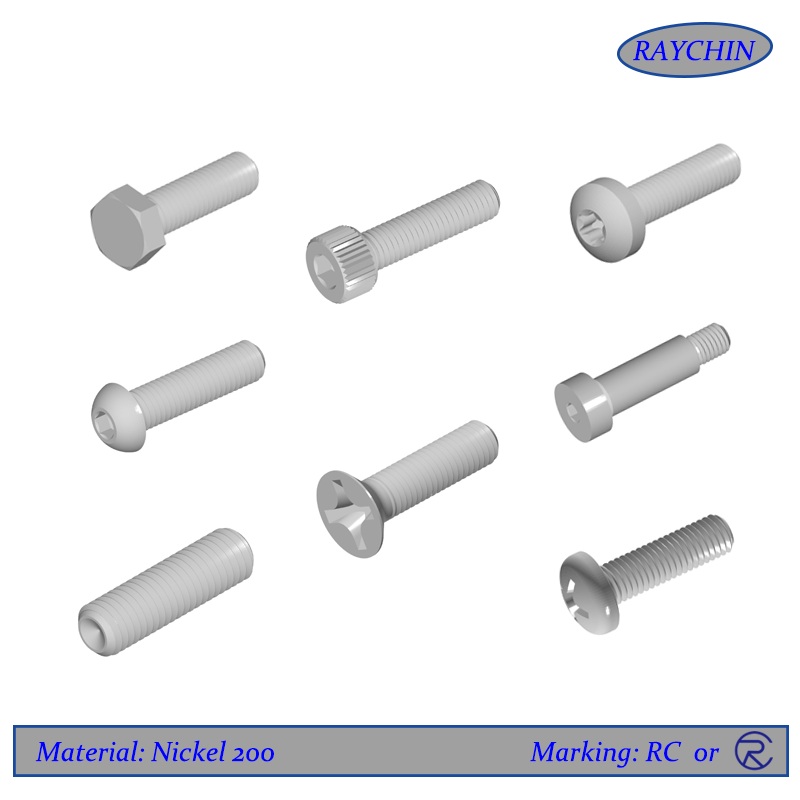

Nickel 200 Screws

Nickel 200 (2.4060) fasteners are made from commercially pure nickel and are best known for their excellent performance in caustic alkali solutions such as caustic soda (NaOH). Nickel 200 also exhibits good performance in acids, especially HF (Hydrofluoric Acid - anhydrous) and hydroxides – but can be attacked by common solutions of hydrochloric or sulfuric acids.

Send Email Details