-

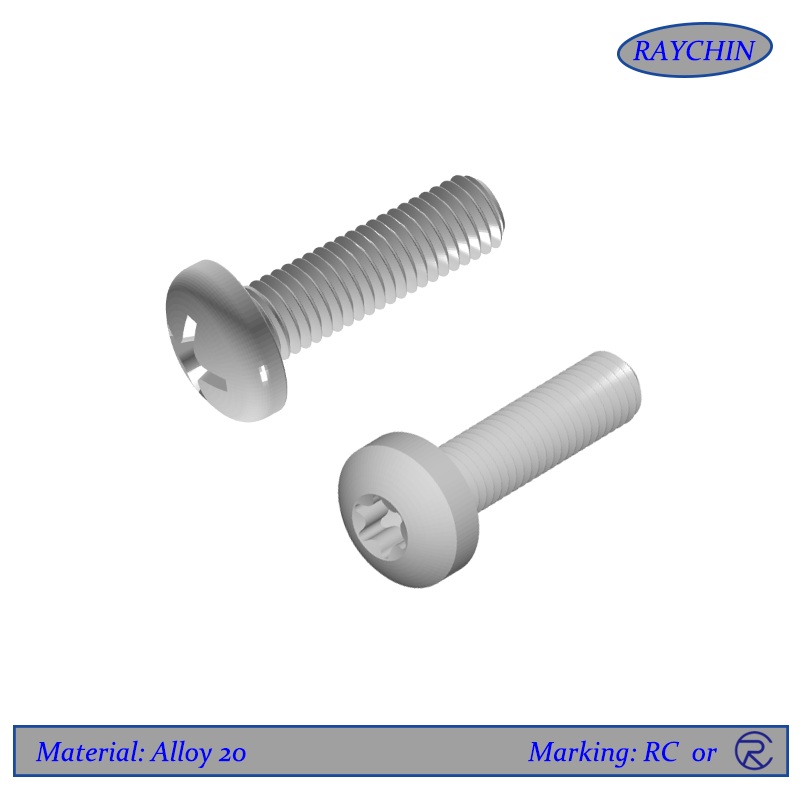

Alloy 20 Pan Head Screws

Also known as Carpenter 20 and 20CB-3, Alloy 20 pan head screws offer users a combination of nickel, chromium, molybdenum, and copper which provides good general corrosion resistance. Alloy 20 pan head screws are best suited for mid-range corrosion use – better than steel alloys but not at the level of high performance nickel based alloys like Hastelloy C276. Alloy 20 is a nickel alloy that was specifically designed to withstand the harsh environment of hot sulfuric acid but also performs well in a variety of other acids. Alloy 20 pan head screws are an ideal choice when you don’t need the corrosion resistance power and price-tag of high performance nickel alloys like Hastelloy C276; but you need something that will give you more protection than 316 stainless steel or even a Super Duplex 2507 stainless steel.

Send Email Details -

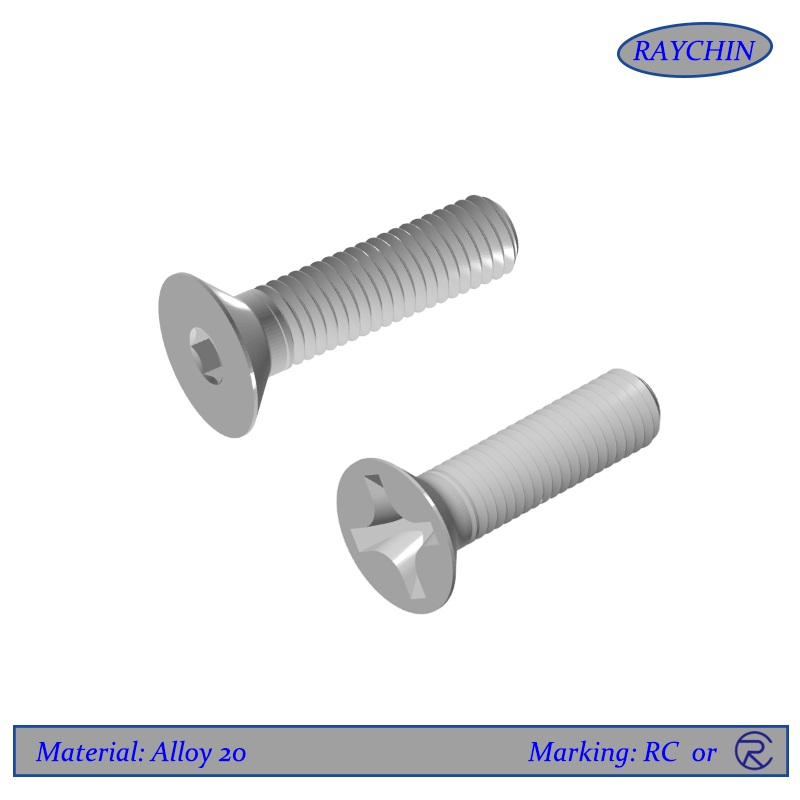

Alloy 20 Flat Head Screws

Also known as Carpenter 20 and 20CB-3, Alloy 20 flat head screws offer users a combination of nickel, chromium, molybdenum, and copper which provides good general corrosion resistance. Alloy 20 flat head screws are best suited for mid-range corrosion use – better than steel alloys but not at the level of high performance nickel based alloys like Hastelloy C276. Alloy 20 is a nickel alloy that was specifically designed to withstand the harsh environment of hot sulfuric acid but also performs well in a variety of other acids. Alloy 20 flat head screws are an ideal choice when you don’t need the corrosion resistance power and price-tag of high performance nickel alloys like Hastelloy C276; but you need something that will give you more protection than 316 stainless steel or even a Super Duplex 2507 stainless steel.

Send Email Details -

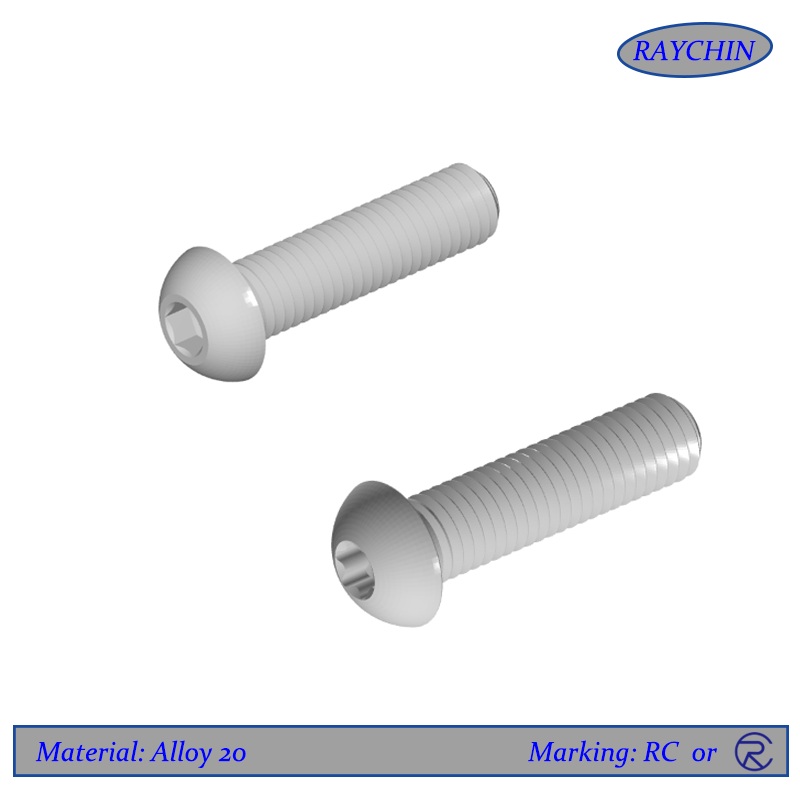

Alloy 20 Button Head Cap Screws

Also known as Carpenter 20 and 20CB-3, Alloy 20 button head cap screws offer users a combination of nickel, chromium, molybdenum, and copper which provides good general corrosion resistance. Alloy 20 button head cap screws are best suited for mid-range corrosion use – better than steel alloys but not at the level of high performance nickel based alloys like Hastelloy C276. Alloy 20 is a nickel alloy that was specifically designed to withstand the harsh environment of hot sulfuric acid but also performs well in a variety of other acids. Alloy 20 button head cap screws are an ideal choice when you don’t need the corrosion resistance power and price-tag of high performance nickel alloys like Hastelloy C276; but you need something that will give you more protection than 316 stainless steel or even a Super Duplex 2507 stainless steel.

Send Email Details -

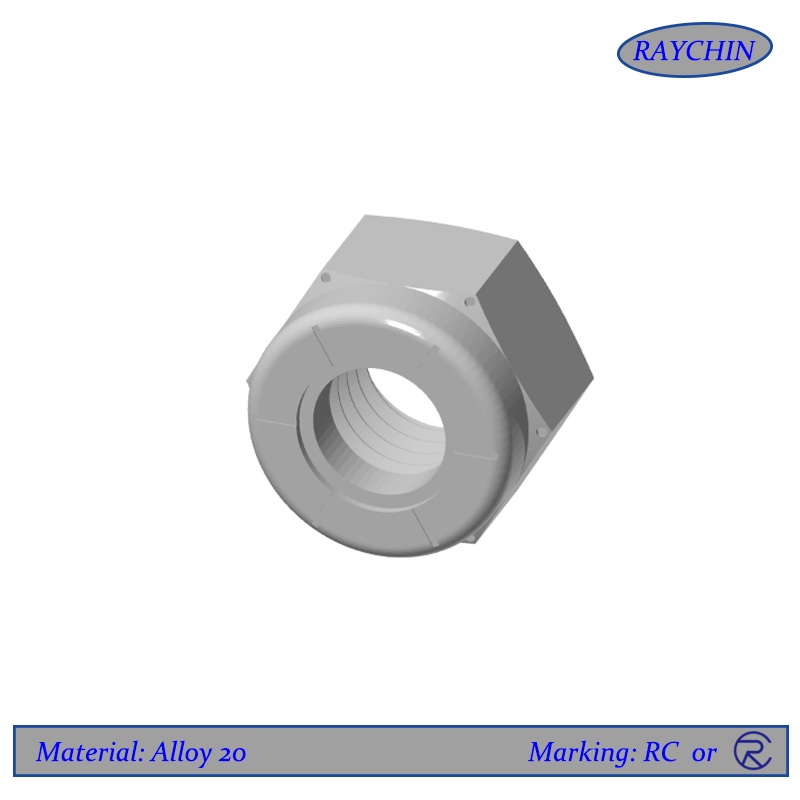

Alloy 20 Lock Nuts

Also known as Carpenter 20 and 20CB-3, Alloy 20 lock nuts offer users a combination of nickel, chromium, molybdenum, and copper which provides good general corrosion resistance. Alloy 20 lock nuts are best suited for mid-range corrosion use – better than steel alloys but not at the level of high performance nickel based alloys like Hastelloy C276. Alloy 20 is a nickel alloy that was specifically designed to withstand the harsh environment of hot sulfuric acid but also performs well in a variety of other acids. Alloy 20 lock nuts are an ideal choice when you don’t need the corrosion resistance power and price-tag of high performance nickel alloys like Hastelloy C276; but you need something that will give you more protection than 316 stainless steel or even a Super Duplex 2507 stainless steel.

Send Email Details -

A286 Hex Bolts

A286 bolts, also known as Alloy 660 bolts are stainless steel alloy which contains iron, nickel and chromium. A286 hex bolts are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 hex bolts provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 hex head bolts are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. -

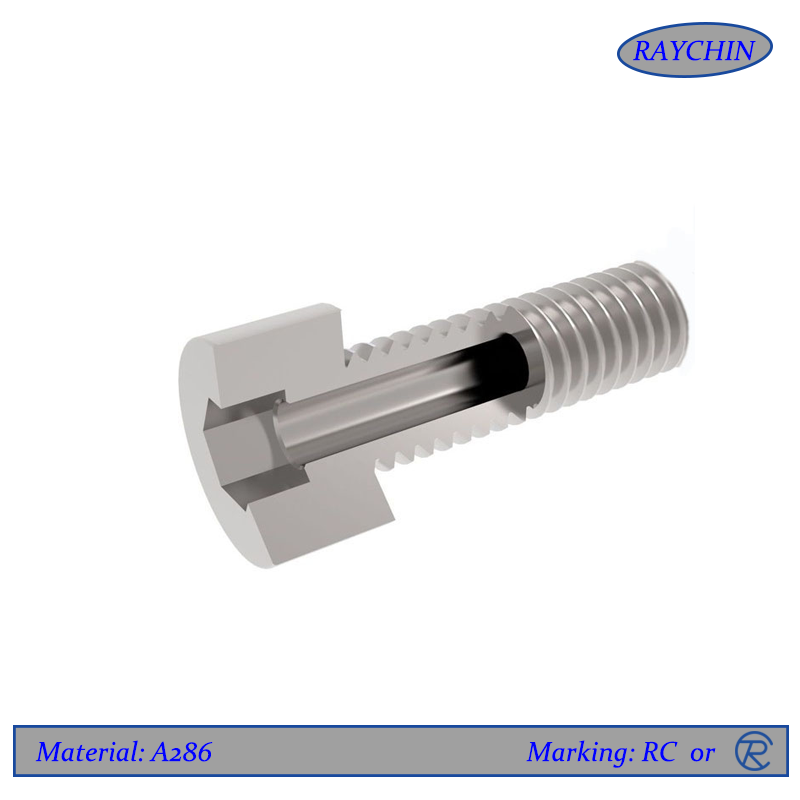

A286 Vented Screws

A286 screws, also known as Alloy 660 screws are stainless steel alloy which contains iron, nickel and chromium. A286 vented screws are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 screws provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 vented screws are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. -

Titanium Threaded Rods

Titanium fasteners are best known for being strong, lightweight, and corrosion resistant. They are critical to many industries including chlor alkali, marine, off-shore oil & gas, desalination, medical, and pulp and paper. Grade 2 and 5 are the most commonly used grades of titanium screws:

Send Email Details

• Grade 2 (UNS R50400 / 3.7035) :Commercially pure titanium and the most common grade for screws.

• Grade 5 (UNS R56400 / 3.7165): Superior strength-to-weight ratio for a unique combination of corrosion and high strength. -

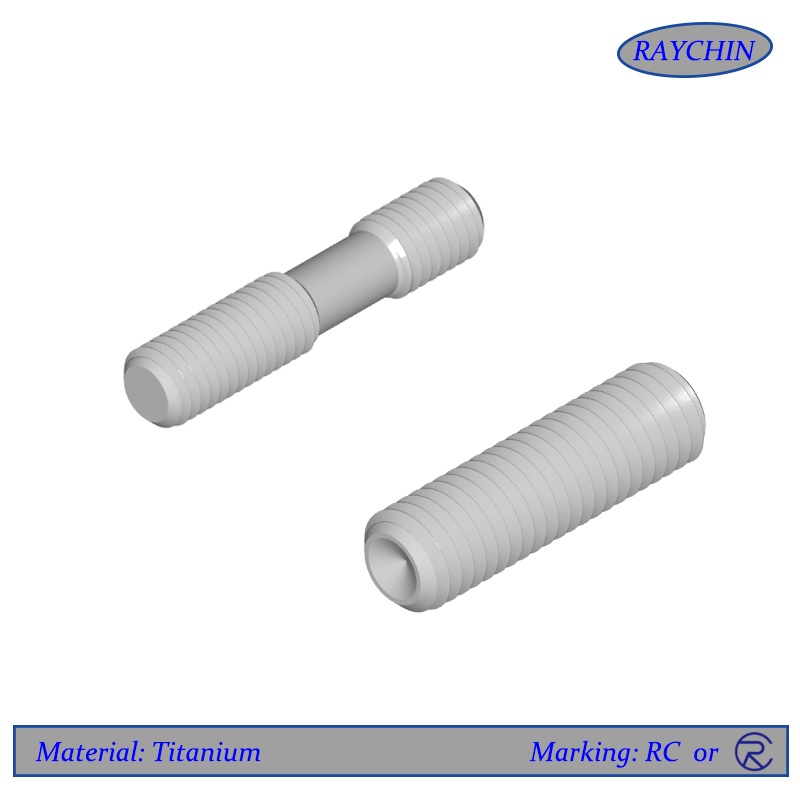

Titanium Studs

Titanium fasteners are best known for being strong, lightweight, and corrosion resistant. They are critical to many industries including chlor alkali, marine, off-shore oil & gas, desalination, medical, and pulp and paper. Grade 2 and 5 are the most commonly used grades of titanium screws:

Send Email Details

• Grade 2 (UNS R50400 / 3.7035) :Commercially pure titanium and the most common grade for screws.

• Grade 5 (UNS R56400 / 3.7165): Superior strength-to-weight ratio for a unique combination of corrosion and high strength. -

Titanium Vented Screws

Titanium fasteners are best known for being strong, lightweight, and corrosion resistant. They are critical to many industries including chlor alkali, marine, off-shore oil & gas, desalination, medical, and pulp and paper. Grade 2 and 5 are the most commonly used grades of titanium screws:

Send Email Details

• Grade 2 (UNS R50400 / 3.7035) :Commercially pure titanium and the most common grade for screws.

• Grade 5 (UNS R56400 / 3.7165): Superior strength-to-weight ratio for a unique combination of corrosion and high strength.