-

Waspaloy Torx Screws

Waspaloy Torx screws are known for their superb high strength at elevated temperatures. Waspaloy is a high performance nickel alloy combined with cobalt, chrome and molybdenum to create it’s unique combination of strength and high temperature stability. Similar to that of Inconel 718 screws, Waspaloy Torx screws exceed the strength and stability of Inconel 718 at elevated temperatures beyond 1400°F. In addition, the oxidation resistance of Waspaloy Torx screws make it an ideal materials for high temperature applications like gas turbines engines, and a variety of other aerospace components.

Send Email Details -

Alloy 330 Torx Screws

Alloy 330 torx screws are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic, nickel-chromium-iron-silicon alloy, 330 torx screws also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Send Email Details -

Alloy 20 Torx Screws

Also known as Carpenter 20 and 20CB-3, Alloy 20 torx screws offer users a combination of nickel, chromium, molybdenum, and copper which provides good general corrosion resistance. Alloy 20 torx screws are best suited for mid-range corrosion use – better than steel alloys but not at the level of high performance nickel based alloys like Hastelloy C276. Alloy 20 is a nickel alloy that was specifically designed to withstand the harsh environment of hot sulfuric acid but also performs well in a variety of other acids. Alloy 20 torx screws are an ideal choice when you don’t need the corrosion resistance power and price-tag of high performance nickel alloys like Hastelloy C276; but you need something that will give you more protection than 316 stainless steel or even a Super Duplex 2507 stainless steel.

Send Email Details -

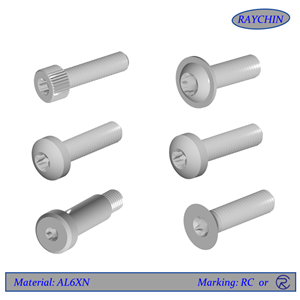

AL6XN Torx Screws

Originally developed to combat sea water corrosion, AL6XN has expanded its role as being good mid-range corrosion resistant alloy. AL6XN torx screws are a low carbon, high purity, nitrogen-bearing "super-austenitic" stainless alloy. Also considered a 6Moly alloy, AL6XN screws are similar in chemistry and capabilities to Alloy 926 and SMO 254. With a higher nickel and molybdenum content than Duplex 2205 and Super Duplex 2507, it delivers better corrosion resistance while giving a more cost effective alternative to nickel super alloys like Inconel or Hastelloy in moderately corrosive conditions.

Send Email Details -

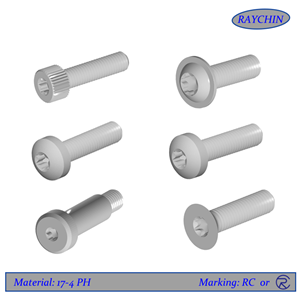

17-4 PH Torx Screws

17-4 PH Torx screws are made from a precipitation hardened stainless steel most known for its exceptional strength and its ability to maintain its mechanical properties to 600°F. Compared to 316 stainless steel, 17-4 PH Torx screws yield strength is up over 4 times greater. When compared to Duplex 2205 screws, the yield strength of 17-4 PH can be up to 2-½ times greater. 17-4 Torx screws are available in 8 different aged (precipitation hardened) conditions offering a variety of mechanical properties.

Send Email Details