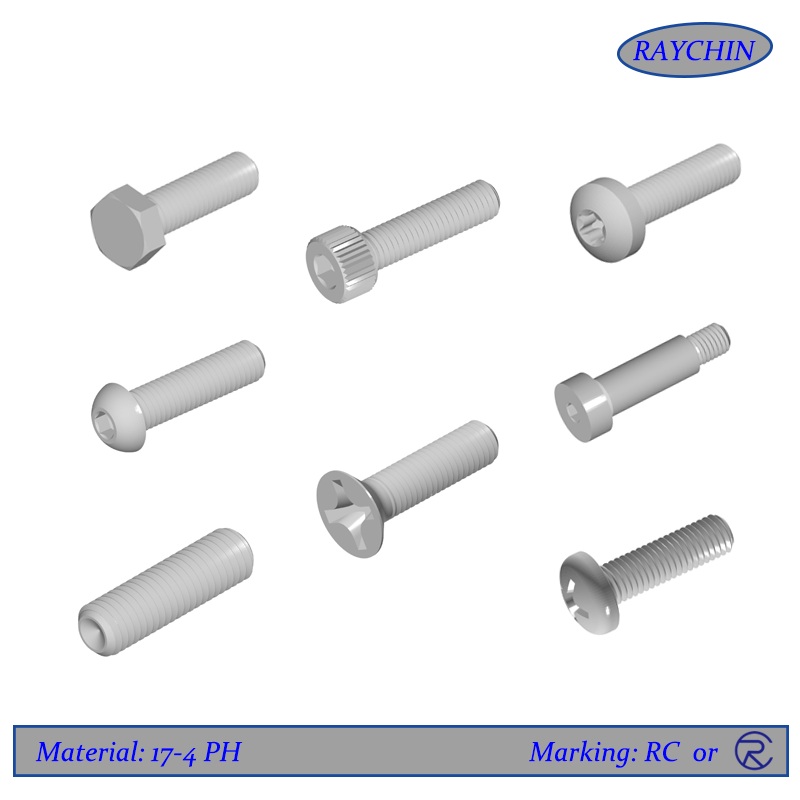

17-4 PH Hex Bolts

17-4 PH Hex Head Bolts

17-4 PH hex head bolts are made from a precipitation hardened stainless steel most known for its exceptional strength and its ability to maintain its mechanical properties to 600°F. Compared to 316 stainless steel, 17-4 PH bolts yield strength is up over 4 times greater. When compared to Duplex 2205 bolts, the yield strength of 17-4 PH can be up to 2-½ times greater.

17-4 PH hex head bolts are available in 8 different aged (precipitation hardened) conditions offering a variety of mechanical properties (see below).

An extremely strong precipitation hardened stainless steel

•Well suited for high strength applciaitons

•Up to 4x stronger than 316 stainless steel

•Maintains its mechanical strength up to 600°F

•17-4PH Chemistry & Specifications

•17-4 PH hex head bolt features and benefits

•17-4PH Datasheet

Resources: 17-4PH Torque Specs

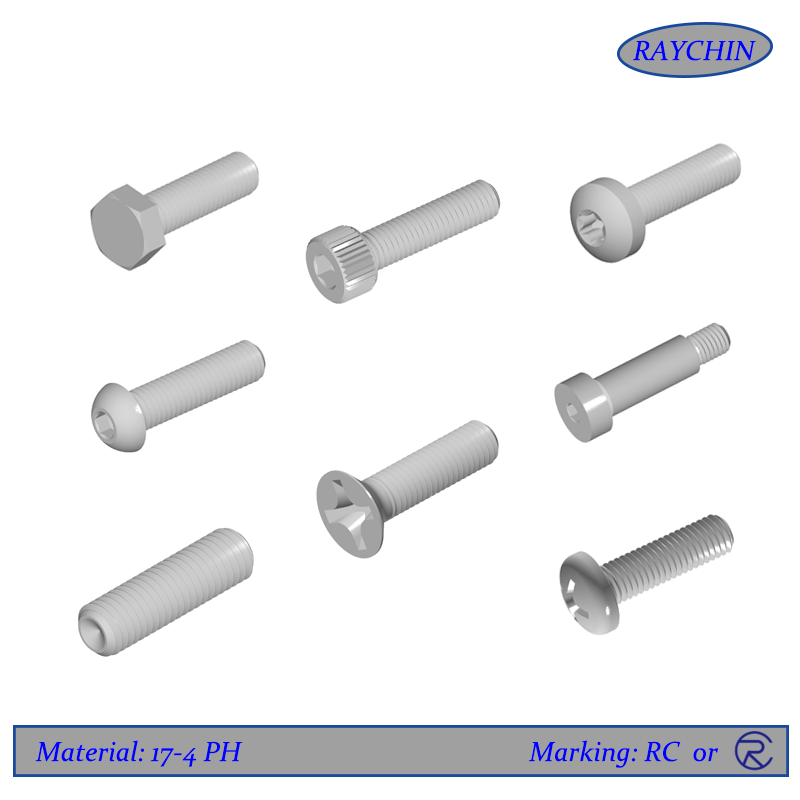

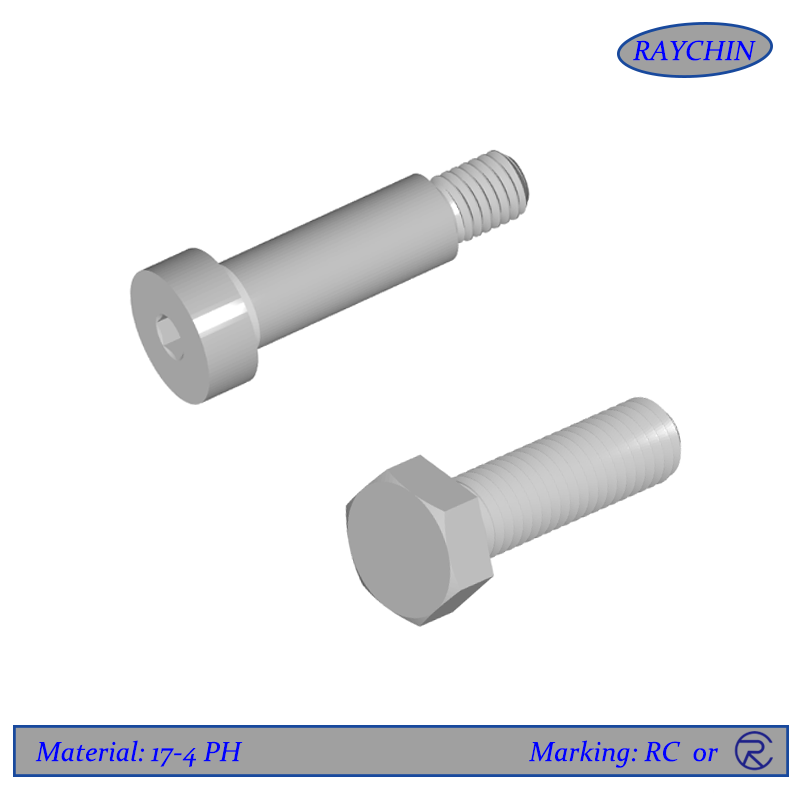

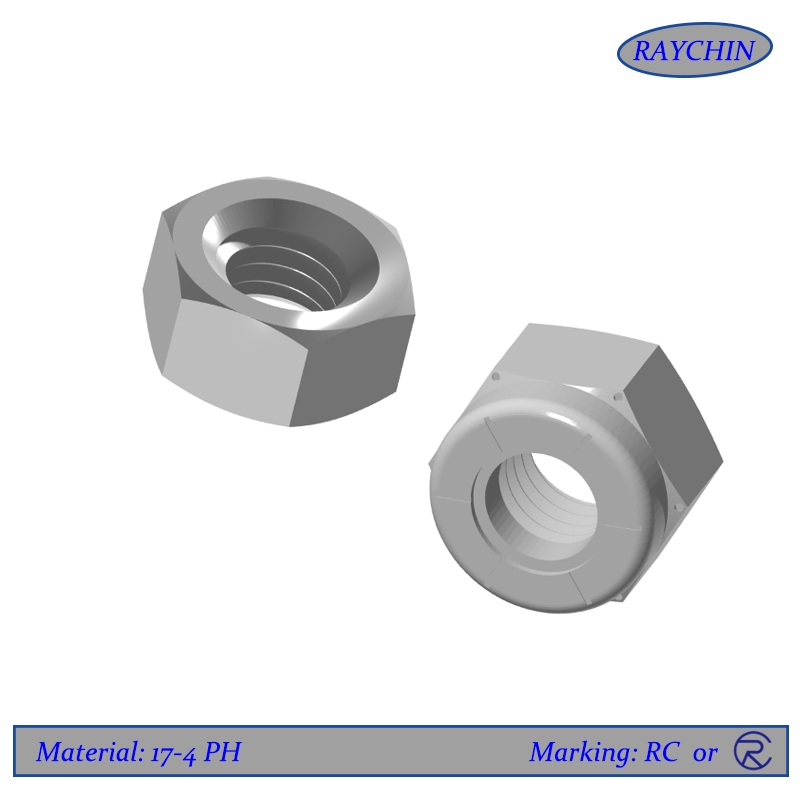

17-4 PH Bolt Types: Hex Bolts, Shoulder Bolts

17-4 PH Hex Head Bolt Features and Benefits

It is important to differentiate between a 17-4 PH hex head bolt and hex head cap screw. Often people assume they are the same, but they are actually very different fasteners in terms of how they are manufactured, as well as from an application perspective. Regardless of your choice, 17-4 PH hex heads offer strong, stable joints because of their large head service.

The Hex Comparison

Hex Head Bolts | Hex Head Cap Screw |

· Hex bolts have a flat end and lack the washer face under the head. · Appropriate for when mechanical properties are more important than dimensional tolerances. | · Features flat washer facing under the bolt head. · Also called a finished hex bolt. · Has tighter tolerances on the body dimensions. · Best used for precise applications where tight tolerances on the body dimensions are required. |

17-4PH Chemistry & Specifications

17-4PH Specifications: UNS S17400, AISI 630, ASTM A564-630, Werkstoff 1.4542, AMS 5604 Sheet, Strip and Plate, ASTM A 693 Plate

17-4PH | Fe | Cr | Ni | Cu | Mn | Si | Mo | Nb+Ta | C | P | S |

Min% |

| 15.0 | 3.0 | 3.0 | - | - | - | - | - | - | - |

Max% | Bal | 17.5 | 5.0 | 5.0 | 1.0 | 1.0 | 0.50 | 0.45 | 0.07 | 0.04 | 0.03 |

ASTM F593, Grade 630

This specification covers seven groups of stainless steel alloys, with ASTM F593, Grade 630 applying 17-4PH. ASTM F593 Grade 630 covers the requirements for 17-4PH stainless steel bolts, hex cap screws, and studs sized 0.25 to 1.50 inches, inclusive, in nominal diameter. It is intended for common use and for service applications requiring general corrosion resistance.

| Full-Size Tests | Machined Specimen Tests |

Stainless Steel Alloy Group | Condition | Alloy Mechanical Property Marking | Nominal Diameter (inches) | Tensile Strength (ksi) | Yield Strength (ksi) | Rockwell Hardness | Tensile Strength (ksi) | Yield Strength | Elongation % |

7(630) | AH | F593U | 1/4 to 1.5 IN | 135 to 170 | 105 | C28 to38 | 135 | 105 | 16 |

Common 17-4 Fastener Conditions: Aged Conditions vs Tensile Strength

Aged Condition | Ultimate Tensile (ksi) | Yield Strength at 0.2% Offset (ksi) | Elongation % | Hardness Rc |

H900 | 200 | 185 | 14 | 40-47 |

H925 | 190 | 175 | 14 | 38-45 |

H1025 | 170 | 165 | 15 | 35-42 |

H1075 | 165 | 150 | 16 | 33-39 |

H1100 | 150 | 135 | 17 | 32-38 |

H115C | 145 | 125 | 19 | 28-37 |

H1150-M | 125 | 85 | 22 | 26-36 |

Annealed | 160 | 145 | 5 | ~35 |