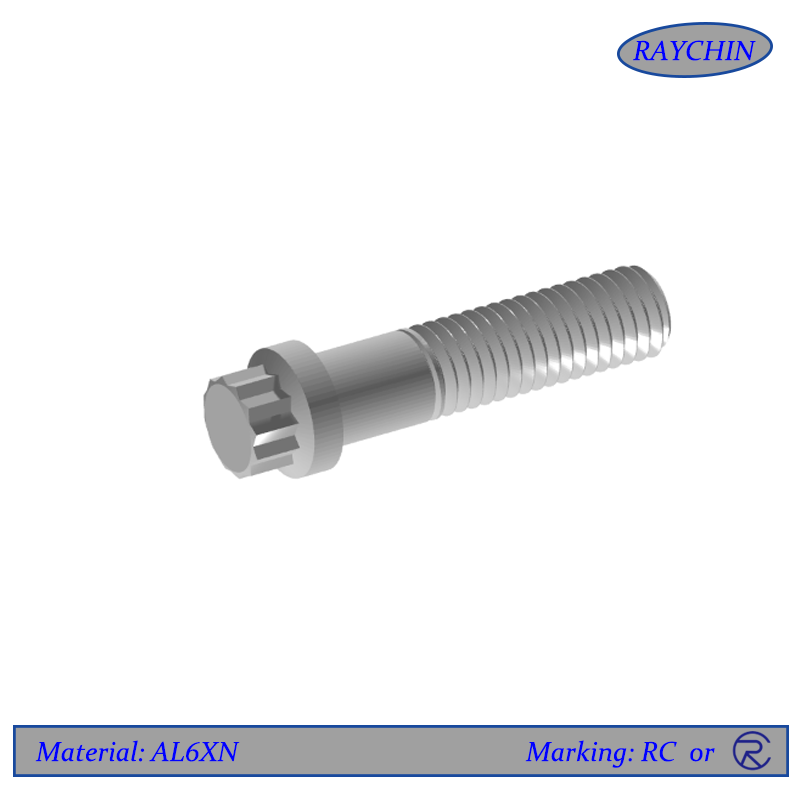

AL6XN 12 Point Screws

Brand RAYCHIN

Product origin China

Delivery time 5-35 DAYS

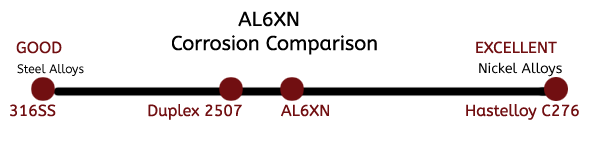

Originally developed to combat sea water corrosion, AL6XN has expanded its role as being good mid-range corrosion resistant alloy. AL6XN 12 point screws are a low carbon, high purity, nitrogen-bearing "super-austenitic" stainless alloy. Also considered a 6Moly alloy, AL6XN screws are similar in chemistry and capabilities to Alloy 926 and SMO 254.With a higher nickel and molybdenum content than Duplex 2205 and Super Duplex 2507, it delivers better corrosion resistance while giving a more cost effective alternative to nickel super alloys like Inconel or Hastelloy in moderately corrosive conditions.

AL6XN 12 Point Screws

Originally developed to combat sea water corrosion, AL6XN has expanded its role as being good mid-range corrosion resistant alloy. AL6XN 12 point screws are a low carbon, high purity, nitrogen-bearing "super-austenitic" stainless alloy. Also considered a 6Moly alloy, AL6XN screws are similar in chemistry and capabilities to Alloy 926 and SMO 254.With a higher nickel and molybdenum content than Duplex 2205 and Super Duplex 2507, it delivers better corrosion resistance while giving a more cost effective alternative to nickel super alloys like Inconel or Hastelloy in moderately corrosive conditions.

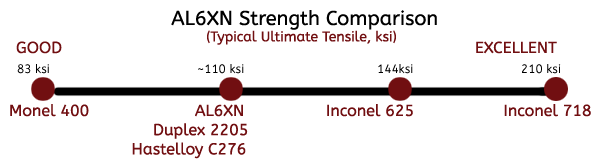

A mid-ranged corrosion resistant 6Mo alloy with good strength

· Good corrosion resistance to moderate acids & sea-water

· 50% stronger than stainless steel

· Usable temperature limit of 1000°F

· AL6XN chemistry & specifications

· 12 point screw features and benefits

· AL6XN Datasheet

Corrosion Resistance

• Moderate general corrosion resistance

• Excellent chloride / salt water protection

• Good performance in phosphoric acid

• Moderate resistance to nitric acid

Chemical Resistance

In chemical processes which utilize chlorides, such as paper mills and waste water, stress corrosion cracking (SCC) is a common culprit for 316L stainless failures. Duplex alloys will outlast environments that will cause SCC in 316 stainless, but for more severe low PH environments, 12 point screws made from higher nickel content alloys like AL6XN will generally work better. For the most extreme situations, alloys with >45% nickel content like Hastelloy are often considered.

Outstanding Resistance to Salt Water

Seawater is where AL6XN 12 point screws outperform so many alloys providing protection to stress corrosion cracking, pitting and crevice corrosion in a broad range of marine applications. AL6XN 12 point screws contain a minimum of 6% molybdenum content and it is this addition of molybdenum that provides the greatest protection against pitting and crevice corrosion.

Mechanical Properties

Electrical Resistivity: 535 Ohm-circ mil/ft

Ultimate Tensile Strength: 108 ksi

0.2% Yield Strength: 53 ksi

Density: 0.291 lb/in 3

Chemistry

• High molybdenum content provides enhanced corrosion protection in chloride environments.

• Carbon helps to prevent sensitization during welding

• Chromium enhances pitting and crevice corrosion resistance

• The interstitial strengthening effect of nitrogen gives AL6XN 12 point screws good high strength properties

AL6XN Applications

• Desalination plants depend on AL6XN 12 point screws for the salt water corrosion protection

• Pulp bleaching equipment and piping

• The power industry uses AL6XN 12 point screws where salt water and chlorides are present such as steam surface condensers, supercritical, high pressure, feed water heaters, steam surface condensers, flue-gas desulfurization equipment and in nuclear power water piping

• Offshore

• Chemical Processing - processing tanks, vessels and pipes as well as plate and frame heat exchangers.

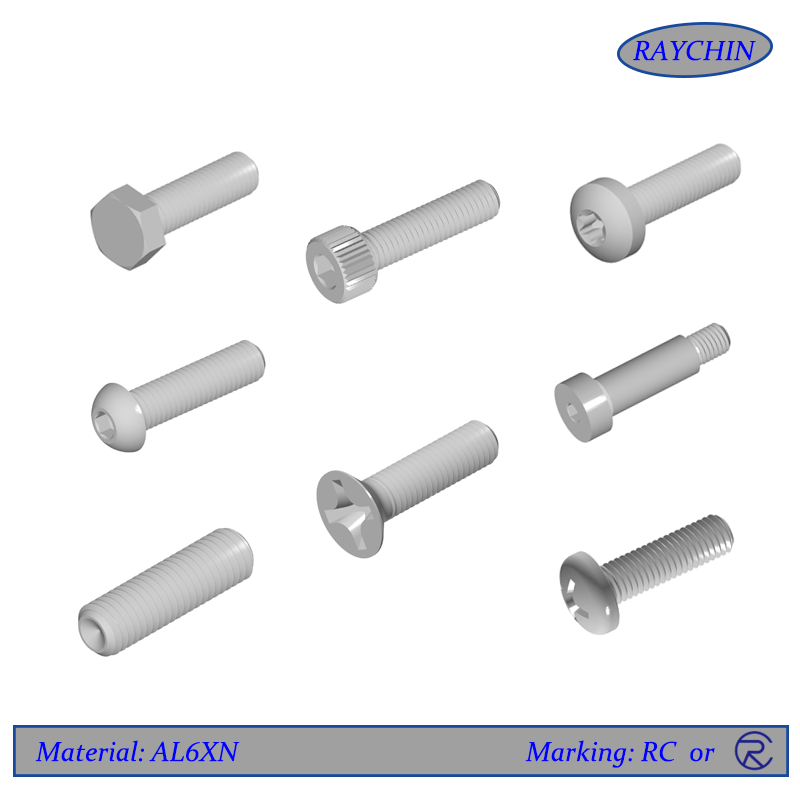

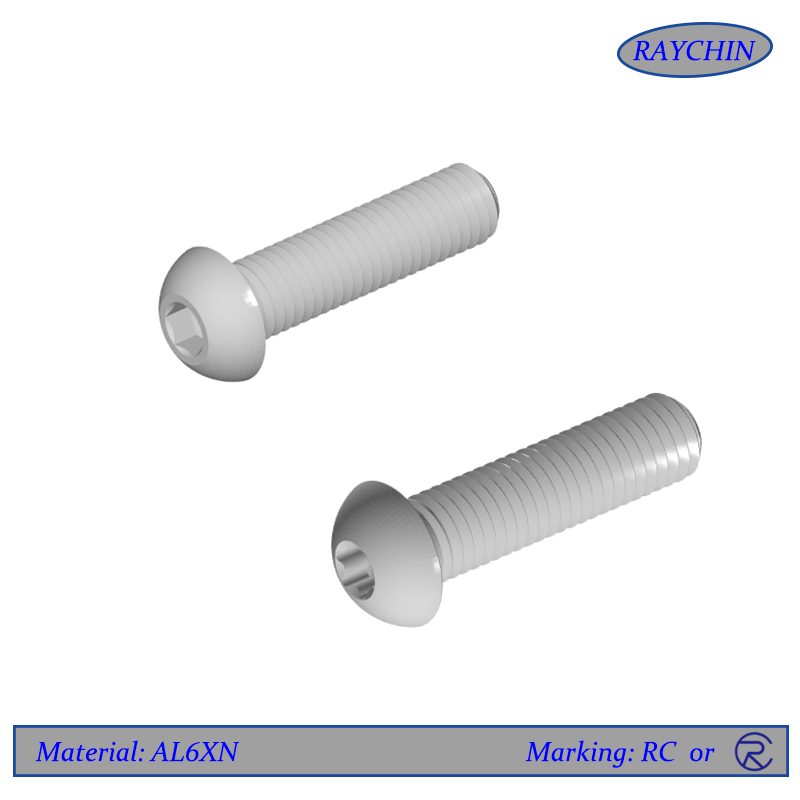

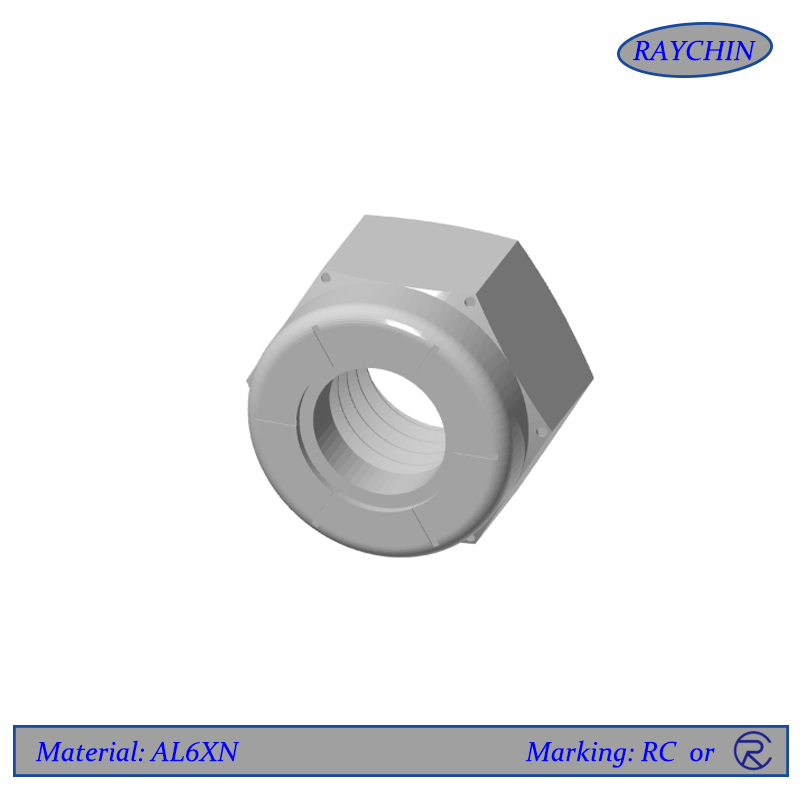

AL6XN Screw Types: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws, Torx Screws

AL6XN Chemical Composition & Specifications

AL6XN Specifications: UNS NO8367, ASTM A 240, ASTM B 688, ASME SA-240, ASME SB-688, ASTM B690, ASTM B691, ASTM A240, ASTM B688, ASME SA-240, ASME SB-688

AL6XN | Fe | Ni | Cr | Mo | Mn | Si | Cu | N | P | C | S |

Min % | - | 23.5 | 20.0 | 6.0 | - | - | - | 0.18 | - | - | - |

Max % | Bal | 25.5 | 22.0 | 7.0 | 2.0 | 1.0 | 0.75 | 0.25 | 0.040 | 0.03 | 0.030 |

AL6XN Mechanical Data

Temperature (°F) | Ultimate Tensile (ksi) | Yield Strength at 0.2% Offset (ksi) | Elongation % |

-450 | 218 | 142 | 36 |

-320 | 196 | 107 | 49 |

Room Temp. | 108 | 53 | 47 |

200 | 100 | 49 | 47 |

400 | 90 | 40 | 46 |

600 | 86 | 36 | 47 |

800 | 87 | 36 | 48 |

1000 | 84 | 34 | 50 |

Corrosion Curves for AL6XN

Media | TYPE 316L | TYPE 317L | ALLOY 904L | AL-6XN | ALLOY 276 |

20% Acetic Acid | 0.12 | 0.48 | 0.59 | 0.12 | 0.48 |

-0.003 | -0.01 | -0.02 | -0.003 | -0.01 | |

45% Formic Acid | 23.41 | 18.37 | 7.68 | 2.40 | 2.76 |

-0.6 | -0.47 | -0.2 | -0.06 | -0.07 | |

10% Oxalic Acid | 44.9 | 48.03 | 27.13 | 7.32 | 11.24 |

-1.23 | -1.14 | -0.69 | -0.19 | -0.28 | |

20% Phosphoric Acid | 0.60 | 0.72 | 0.47 | 0.24 | 0.36 |

-0.02 | -0.02 | -0.01 | -0.006 | -0.009 | |

10% Sodium Bisulfate | 71.57 | 55.76 | 8.88 | 4.56 | 2.64 |

-1.82 | -1.42 | -0.23 | -0.12 | -0.067 | |

50% Sodium Hydroxide | 77.69 | 32.78 | 9.61 | 11.4 | 17.77 |

-1.92 | -0.83 | -0.24 | -0.29 | -0.45 | |

10% Sulfamic Acid | 124.3 | 93.26 | 9.13 | 9.36 | 2.64 |

-3.16 | -2.39 | -0.23 | -0.24 | -0.067 | |

10% Sulfuric Acid | 635.7 | 298.3 | 100.8 | 71.9 | 13.93 |

-16.15 | -7.58 | -2.53 | -1.83 | -0.35 |