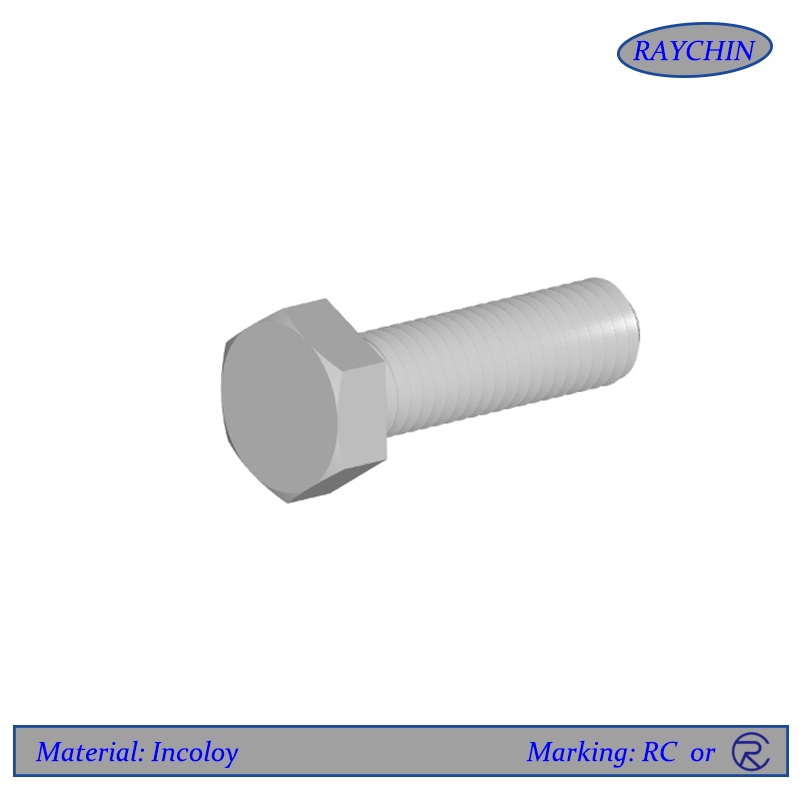

Incoloy Hex Cap Screws

Brand RAYCHIN

Product origin China

Delivery time 5-35 DAYS

Not to be confused with Inconel, Incoloy hex head cap screws are made of a nickel alloy which contains iron and a lower content of nickel. Incoloy is essentially a more economical option to Inconel, yet with more restricted corrosion resistance and temperature limits. Typically, Incoloy is an ideal material for long-term exposure in high temperature environments due to its oxidation, carburization and creep resistance. Incoloy is widely used for its resistance to seawater, brine, sour gas and high chloride environments at elevated temperatures, which make it a popular choice in the oil and gas and power industries.

The most commonly used grades of Incoloy screws are Incoloy 800, 800H, 800HT; Incoloy 825; and Incoloy 925.

Incoloy Hex Head Cap Screws

Not to be confused with Inconel, Incoloy hex head cap screws are made of a nickel alloy which contains iron and a lower content of nickel. Incoloy is essentially a more economical option to Inconel, yet with more restricted corrosion resistance and temperature limits. Typically, Incoloy is an ideal material for long-term exposure in high temperature environments due to its oxidation, carburization and creep resistance. Incoloy is widely used for its resistance to seawater, brine, sour gas and high chloride environments at elevated temperatures, which make it a popular choice in the oil and gas and power industries.

The most commonly used grades of Incoloy screws are Incoloy 800, 800H, 800HT; Incoloy 825; and Incoloy 925.

A Ni-Cr alloy with very good high temperature stability

Good high temperature strength

Good high temperature strengthOxidization and carburization resistant at high temperatures

Good corrosion resistance, which increases with the various grades

Incoloy hex head cap screw features and benefits

Incoloy 800, 800H, 800HT

Incoloy 825

Incoloy 925

Resources: Incoloy Torque Specs

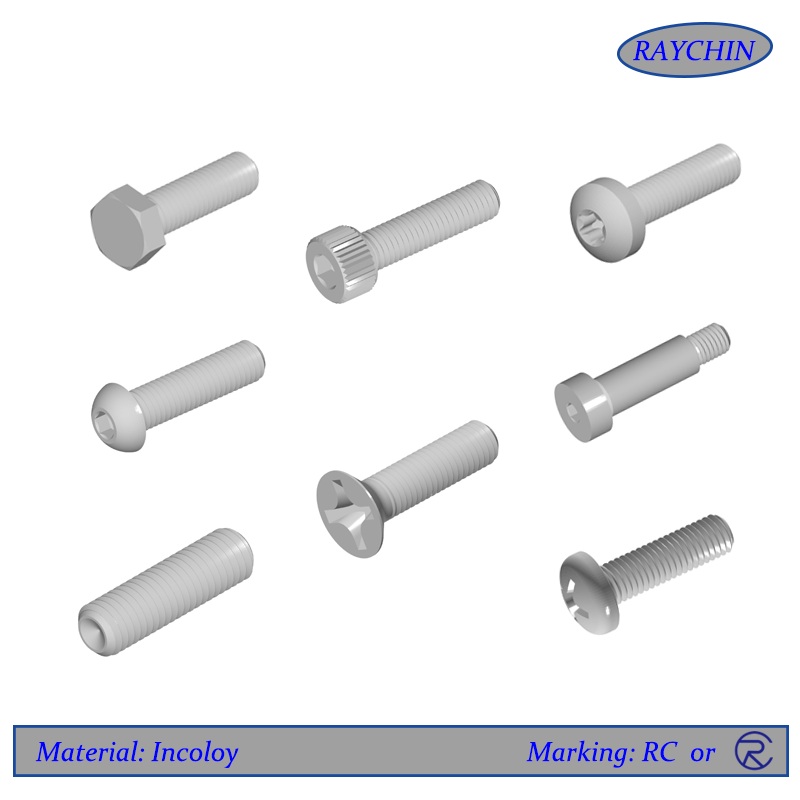

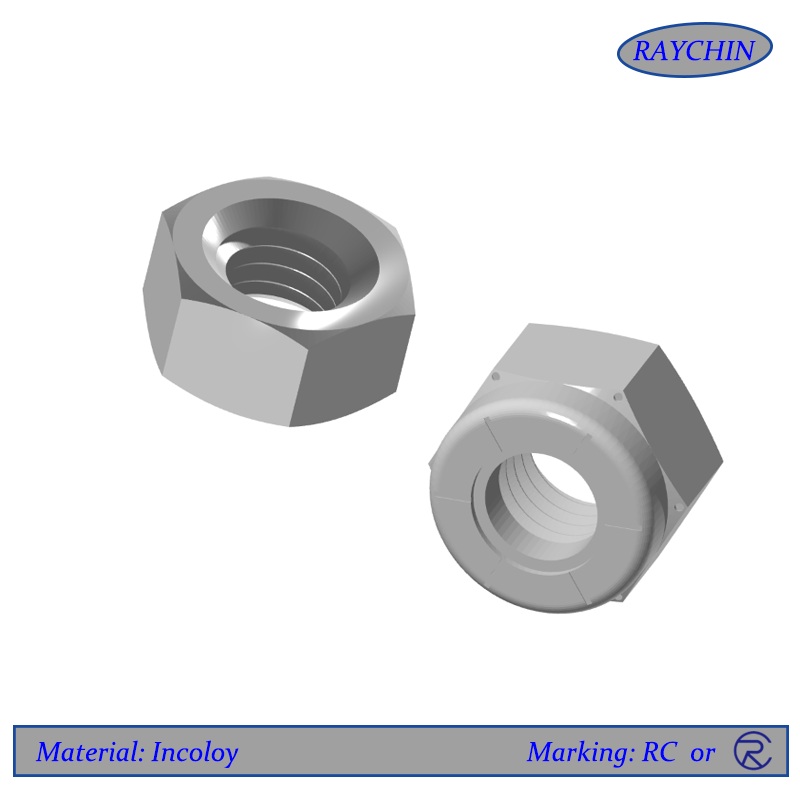

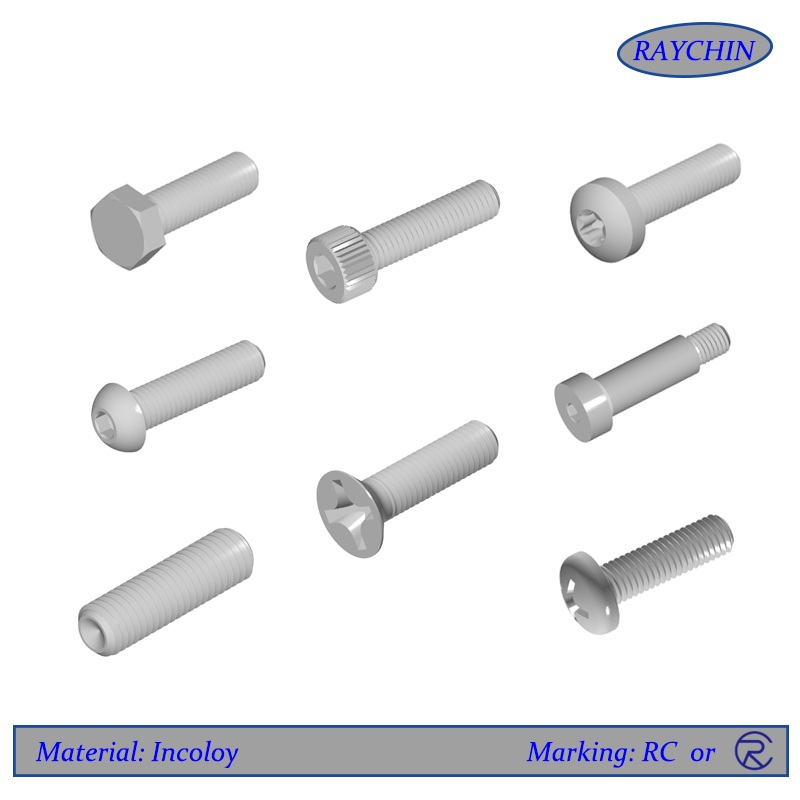

Incoloy Fastener Types: Bolts, Nuts, Screws, Threaded Rods, Washers

Screw Types Available: 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Head Cap Screws, Pan Head Screws, Set Screws, Socket Head Cap Screws, Tamper Resistant Security Screws, Torx Screws, Vented Screws

Incoloy Hex Head Cap Screw Features and Benefits

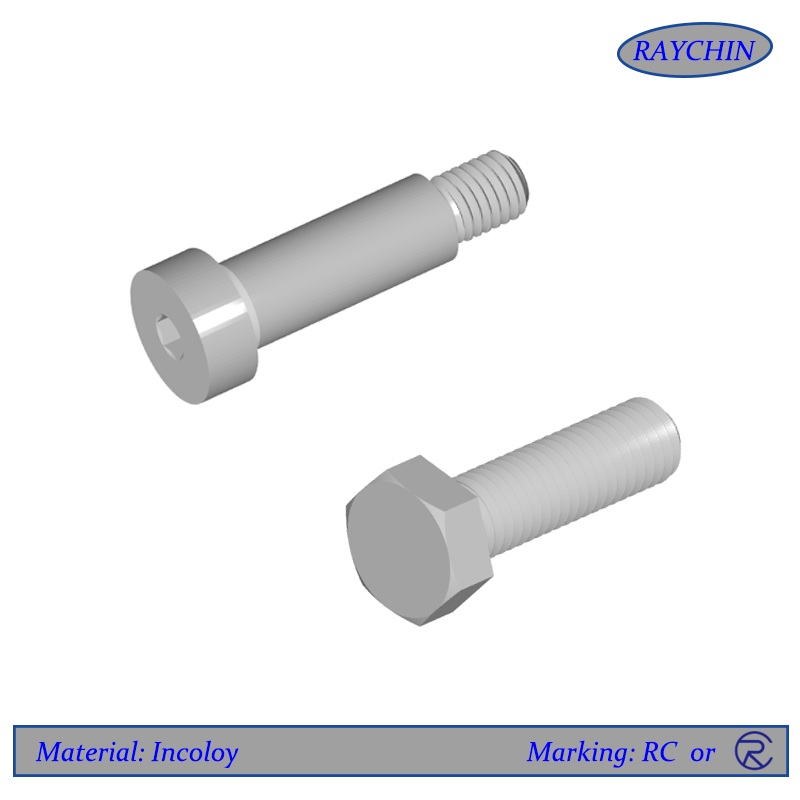

It is important to differentiate between a Incoloy hex head cap screw and hex head bolt. Often people assume they are the same, but they are actually very different fasteners in terms of how they are manufactured, as well as from an application perspective. Regardless of your choice, Incoloy hex heads offer strong, stable joints because of their large head service.

The Hex Comparison

| Hex Head Cap Screw | Hex Head Bolts |

|

|

Incoloy Hex Head Cap Screw Advantages

The most important feature of a Incoloy hex head cap screws is that it has a larger bearing surface area which provide better clamping pressure than other type of fastener such as a socket head cap screw. Additionally, since debris build up is less of an issue with this style of fastener verses a socket head cap screw, they are ideal of dirty applications where particles could clog up a socket. Though Incoloy socket heads are typically used for tight access applications, hex heads can be a better choice when there is only side clearance available for tightening.

Common Incoloy Chemistry, Grades & Specifications

Incoloy 800, 800H, H00HT

Incoloy 800 series screws are best utilized for applications that require stable structure and good strength during prolonged exposure to high temperatures.

Incoloy 800, 800H & 800HT Specifications: UNS N08800/ N08810 / N08811 (800, 800H, 800HT), ASTM B408, ASME SB408, ASTM B564/ASME SB564, EN 10204-3.1, Werkstoff 1.4876 (800), Werkstoff 1.4876 H and 1.4958 (800H), Werkstoff 1.4876 HT and 1.4959 (800HT)

Incoloy 800 | Ni | Fe | Cr | C | AL | T1 | AL-T1 |

Min% | 30 | 39.5 | 19 | - | 0.15 | 0.15 | 0.3 |

Max % | 35 | - | 23 | 0.1 | 0.6 | 0.6 | 1.2 |

Incoloy 800H

Min% | 30 | 39.5 | 19 | 0.05 | 0.15 | 0.15 | 0.3 |

Max % | 35 | 23 | 0.1 | 0.6 | 0.6 | 1.2 |

Incoloy 800H

Min% | 30 | 39.5 | 19 | 0.06 | 0.25 | 0.25 | 0.85 |

Max % | 35 | - | 23 | 0.1 | 0.6 | 0.6 | 1.2 |

Incoloy 825 (2.4858)

Related to the Incoloy 800 series alloys, Incoloy 825 (2.4858) differentiates itself with the additional elements of molybdenum and copper, which provides it improved corrosion resistance.

Incoloy 825 Specifications: UNS N08825, BS 3076NA16, ASTM B 425, ASTM B 564, ASME SB 425, ASME SB 564, ASME Code Case N-572, DIN 17752, DIN 17753, DIN 17754, VdTÜV 432, ISO 9723, ISO 9724, ISO 9725, Werkstoff Nr 2.4858

Incoloy 825 | Ni | Fe | Cr | Mo | Cu | Ti | C | Mn | S | Si | Al |

Min % | 38 | 22 | 19.5 | 2.5 | 1.5 | 0.6 | - | - | - | - | - |

Max % | 46 | - | 2.35 | 3.5 | 3.0 | 1.2 | 0.05 | 1.0 | 0.03 | 0.5 | 0.2 |

Incoloy 925

Incoloy 925 is a precipitation hardened alloy. It offers comparable corrosion resistance to it’s sister alloy Incoloy 825, but with the increased strength resulting from the age hardening process.

Incoloy 925 Specifications: UNS N09925, ASTM B637, NACE MR0175

Incoloy 925 | Ni | Fe | Cr | Mo | Cu | Ti | C | Mn | S | Si | Al | Nb |

Min % | 42 | 22 | 19.5 | 2.5 | 1.5 | 1.9 | - | - | - | - | 0.1 | - |

Max % | 46 | - | 22.5 | 3.5 | 3.0 | 2.4 | 0.03 | 1.0 | 0.03 | 0.5 | 0.5 | 0.5 |