Nickel 200 Bolts

Brand RAYCHIN

Product origin CHINA

Delivery time 5-35 DAYS

Nickel 200 (2.4060) fasteners are made from commercially pure nickel and are best known for their excellent performance in caustic alkali solutions such as caustic soda (NaOH). Nickel 200 also exhibits good performance in acids, especially HF (Hydrofluoric Acid - anhydrous) and hydroxides – but can be attacked by common solutions of hydrochloric or sulfuric acids.

Nickel 200 Fasteners - Bolts, Screws & Nuts

Nickel 200 (2.4060) fasteners are made from commercially pure nickel and are best known for their excellent performance in caustic alkali solutions such as caustic soda (NaOH). Nickel 200 also exhibits good performance in acids, especially HF (Hydrofluoric Acid - anhydrous) and hydroxides – but can be attacked by common solutions of hydrochloric or sulfuric acids.

Ideal for caustic alkali corrosive solutions

· Excellent corrosion resistance to caustic soda

· Moderate general corrosion resistance

· Chemistry, specifications & Mechanical Data

· Nickel 200 fastener styles

· Availability of Nickel 200 fasteners

· Nickel 200 datasheet

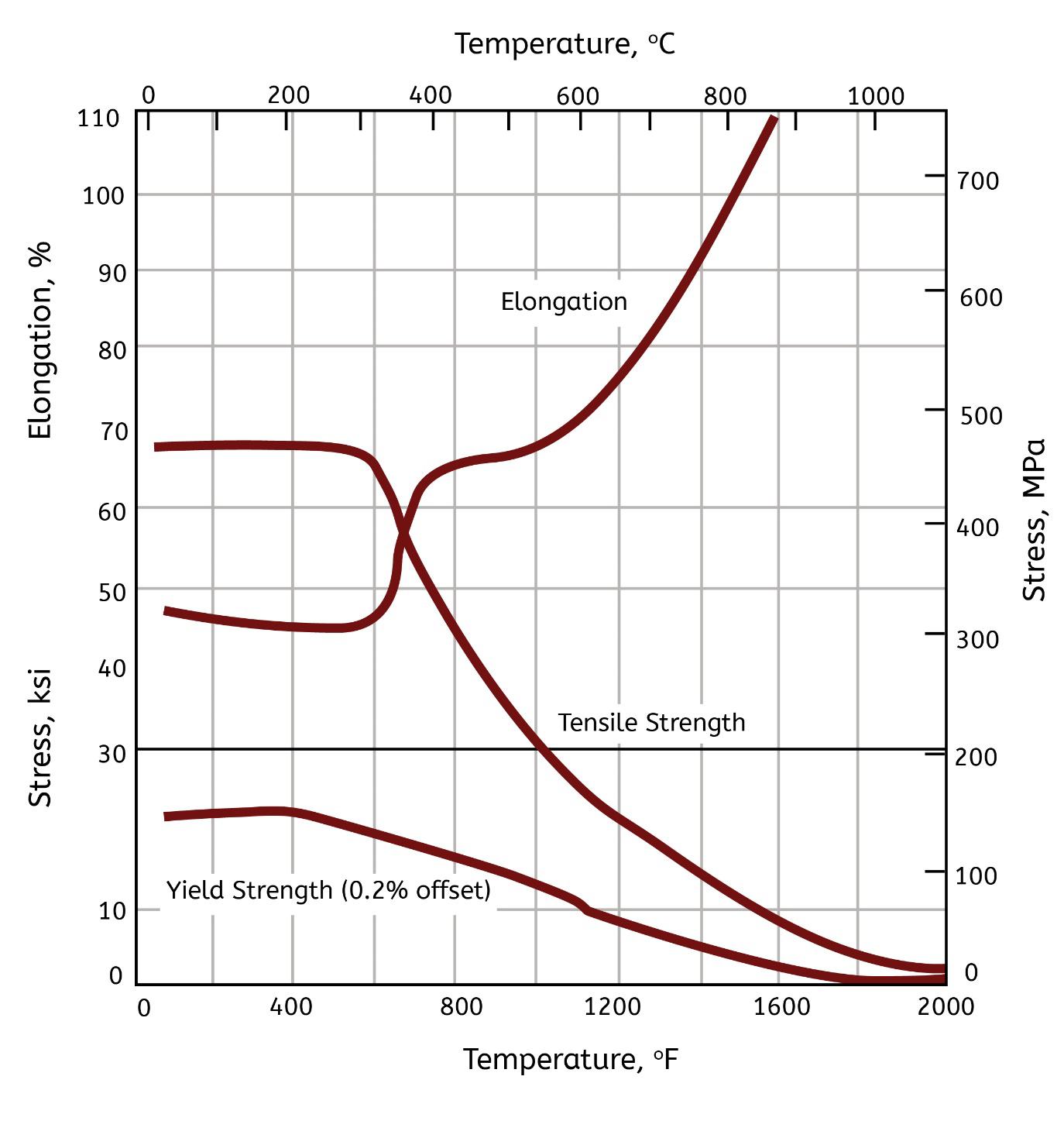

From a mechanical perspective, Nickel 200 bolts have good ductility and low hardness, so they are tough, but not particularly strong (60-85 KSI UTS). See Tensile, Yield & Elongation Chart.

Corrosion

Nickel 200 screws are resistant to corrosive environments, most notably reducing chemicals. They offer outstanding protection to caustic alkaline solutions. However, Nickel 200 fasteners will be severely attacked in oxidizing salt solutions.

Chemical Resistance

• Sodium Hydroxide (NaOH): Excellent resistance to all concentrations of caustic soda.

• Alkalis: Excellent resistance except for ammonium hydroxide.

• Sulfuric acid: Moderate resistance to nonaerated sulfuric acid solutions near room temperature.

• Hydrochloric: Limited resistance in specific environments only.

• Hydrofluoric: Good resistance to anhydrous hydrofluoric acid even at high temperatures. Nickel 200 it has limited resistance to aqueous HF solutions.

• Important: Oxidizing acid chlorides such as ferric, cupric and mercuric are very corrosive to Nickel 200 fasteners.

General

• 60-85 KSI UTS

• 15-45 KSI Yield

• Typically used in application temperatures less than 600⁰F / 315⁰C

Applications

• Most often used in chemical and electronic processing, especially applications that deal with caustic soda.

• High electrical and thermal conductivity, as well as magnetostrictive properties make Nickel 200 screws useful in electrics and sonic devices.

• Nickel 200 bolts are used in salt production and applications that use sodium hydroxide and fluorine.

Nickel 200 Fastener Availability

Availability

Nickel 200 is available in a wide variety of screw styles. The minimum order quantity is typically around 20 pieces with the normal lead time being about 3 weeks, depending on the complexity of custom requests. So be sure to contact us for specific lead times and any expediting needs.

· Diameter sizes: Standard #00 – 4” in diameter / Metric M1.2 – M48

· Threads: UNC, UNF, UNJ, UNR, Rolled,Cut

· Custom to print available.

· NACE MR0175, ASTM, ASME, MIL specifications, DFAR and Domestic available

Expediting Options

We understand you may have critical needs that require expedited lead times. Please let us know when requesting a quote so we can do our best to help.

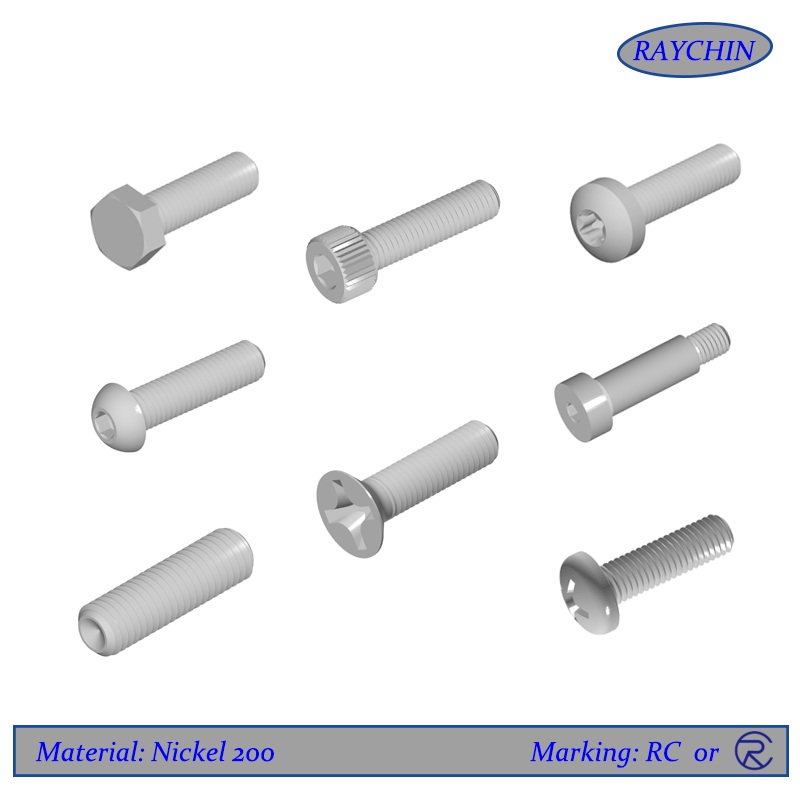

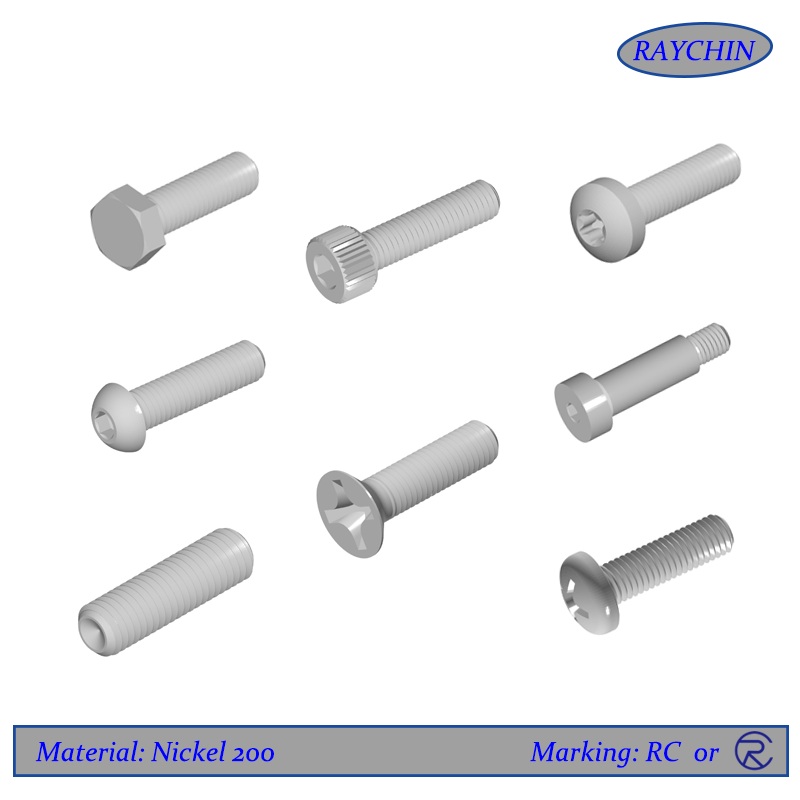

Nickel 200 Fastener Styles

Nickel 200 Screws | 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Head Cap Screws, Pan Head Screws, Security Screws, Set Screws, Socket Head Cap Screws, Vented Screws |

|

Nickel 200 Bolts | Hex Head Bolts, Shoulder Bolts, Wedge Anchor Bolts | • DIN 931 |

Nickel 200 Nuts | Hex Nuts, Lock Nuts | • DIN 439 / ISO 4035 |

Nickel 200 Threaded Products | Studs, Threaded Rods | • DIN 975 |

Nickel 200 Washers | Flat Washers, Lock Washers | • DIN 125 / ISO 7089 / ISO 7090 |

Nickel 200 Chemistry and Specifications

NICKEL 200 SPECIFICATIONS: UNS N02200, EN 2.4060, EN 2.40666

Nickel 200 | Ni | Fe | Mn | Si | Cu | C | S |

99.0min | 0.40max | 0.35max | 0.35max | 0.25max | 0.15max | 0.01max |

Nickel 200 Aqueous Corrosion Data

Media | Common Name | Temperature °F (°C) | Corrosion Rate (mpy |

5% CH3CO2H with Air | Accetic Acid | 70 (21) | 40 |

10% CH3CO2H | Accetic Acid | 86(30) | 3.4 |

56% CH3COzH | Accetic Acid | 176(80) | 66 |

85% CH3CO2H with Air | Accetic Acid | 70 (21) | 400 |

98% CH3COzH | Accetic Acid | 241(116) | 12 |

50% NaOH | Caustic Soda | 195 (90) | 0.55 |

50% NaOH | Caustic Soda | 310(155) | 0.5 |

75% NaOH | Caustic Soda | 250(120) | 1 |

90% CH2O2 | Formic Acid (liquid) | 70 (21) | 4 |

90% CH2O2 | Formic Acid (vapor) | 70 (21) | 7 |

1% HCI | Hydrochloric Acid | 214(101) | 680 |

10% HCI | Hydrochloric Acid | 86(30) | 80 |

10% HCI | Hydrochloric Acid | 221(105) | 8,000 |

10% HNO3 | Nitric Acid | 216(102) | 12,000 |

10% H3PO4 | Phosphoric Acid | 75 (24) | 0.6 |

10% H3PO4 | Phosphoric Acid | 214(101) | 154 |

40% H3PO4 | Phosphoric Acid | 75 (24) | 1 |

500ppm NaClO | Sodium Hypochlorite | 77(25) | 0.8 |

2% H2SO4 | Sulfuric Acid | 70 (21) | 2 |

5% H2SO4 | Sulfuric Acid | 140 (60) | 10 |

5% H2SO4 with Air | Sulfuric Acid | 86(30) | 61 |

19% H2SO4 | Sulfuric Acid | 223(106) | 110 |

20% H2SO4 | Sulfuric Acid | 70 (21) | 4 |

50% H2SO4 with Air | Sulfuric Acid | 86(30) | 16 |

50% H2SO4 | Sulfuric Acid | 255(124) | 1,000 |

93% H2SO4 with Air | Sulfuric Acid | 86(30) | 10 |

Nickel 200 Temperature vs. Strength

Nickel 200 Screws

12 Point Screws 12 Point Screws | Nickel 12 point screws are an ideal choice when higher torque than a socket head cap screw is needed. The only drawback is they are be less economical due to the complex head design. Available in 1/4" or larger sizes. | • IFI-115 • MIL SPEC • DIN 34822 • DIN 34821 |

Button Head Cap Screws Button Head Cap Screws | Offering a wide clamping area and low profile, Nickel 200 button head screws are best suited for fastening a material that is too thin to counter bore. | • ASME B18.3 • ASME 18.3.4M • DIN 7380 / ISO 7380 |

| Most commonly offered in an 82° countersink angle, Nickel 200 flat head screws but can be customized to other angles from 60° -120°. These screws are designed to be flush with the surface. Nickel 200 flat heads are available in slotted and socket drivers. Phillips, torx and other tamperproof drivers can also be made upon request. | • ASME B18.3 • ASME B18.3.6 • DIN 963 / ISO 2009 • DIN 965 / ISO 7046 • DIN 7991 / ISO 10642 | |

Hex Head Cap Screws Hex Head Cap Screws | Nickel 200 hex head cap screws feature an added washer face to the bolt head (lacking on a hex bolt) which provides tighter dimensional tolerances. Ideal for a high clamping force applications with ease of access. Generally availabe in #2 - 1/2" sizes and metric sizes. | • ASME B18.6.3 • DIN 931 / ISO 4014 • DIN 933 / ISO 4017 • DIN 961 / ISO 8676 |

Pan Head Screws Pan Head Screws | Nickel 200 pan head screws have a rounded head style and typically featured a slotted driver. They are best for small diameter fasteners and low torque applications. | • ASME B18.6.3 • DIN 7985 • DIN 921 • DIN 85 / ISO 1580 • DIN 84 / ISO 1207 (cheese head) • DIN 966 / ISO 7047 (raised counter sunk) |

Security Screws Security Screws | Nickel 200 security screws provide a solution to unwanted tampering or removal due to the fact that they cannot be removed using an ordinary driver. Nickel 200 security screws can be made in a wide variety of driver styles, as well as custom per print. | |

Set Screws Set Screws | Nickel 200 set screws are a headless fastener with a slotted or socket driver on one end and a special point on the other. We offer Nickel 200 set screws in cup, cone, flat, dog and half-dog points. | • ASME B18.3 • DIN 913 / ISO 4026 • DIN 914 / ISO 4027 • DIN 915 / ISO 4028 • DIN 916 / ISO 4029 |

Socket Head Cap Screws Socket Head Cap Screws | Nickel 200 socket head cap are a safe reliable fastening solution for applications with limited access and little clearance. | • ASMET B18.3 • DIN 912 / ISO 4762 • DIN 7984 |

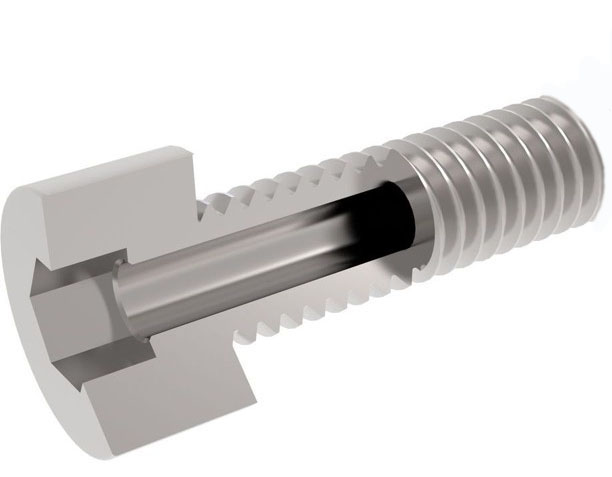

Vented Screws Vented Screws | Nickel 200 vented screws have a vertical hole drilled from the screw head through to the end of the threads. This allows gases and other contaminents to vent. Nickel 200 vented screws are ideal for vacuum / high vacuum applications. Nickel 200 vented screws are available in any head style. |

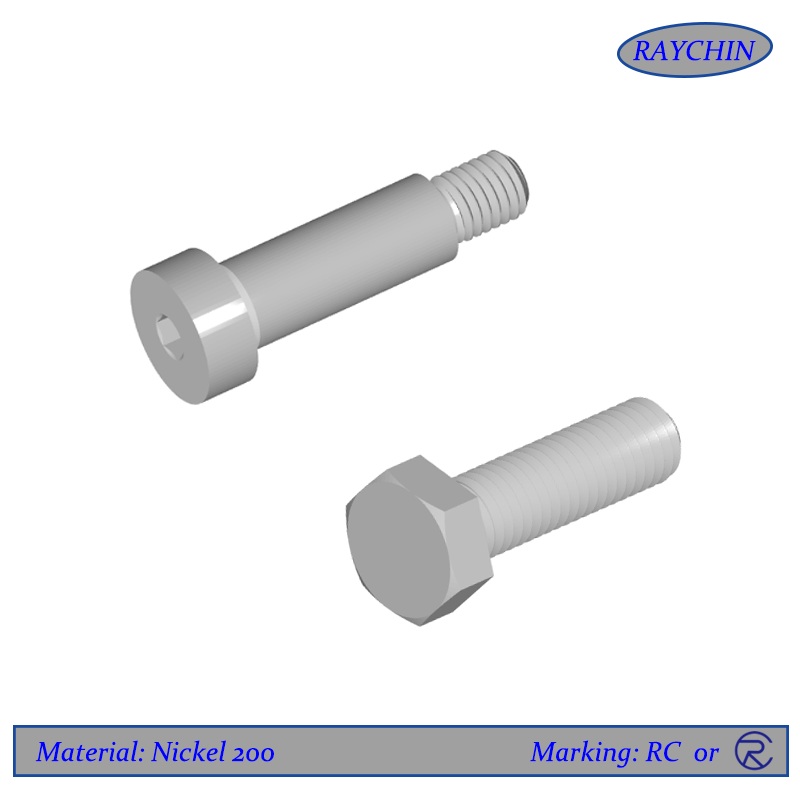

Nickel 200 Bolts

Hex Head Bolts Hex Head Bolts | Nickel 200 hex bolts are similar to hex head cap screws, less the washer face under the head. They are ideal for high clamping force applications with ease access. | • ASME B18.2.1 • DIN 931 / ISO 4014 • DIN 933 / ISO 4017 |

Shoulder Bolts Shoulder Bolts | Nickel 200 shoulder bolts are made up of a head, smooth shoulder section (for rotating parts) and threaded segment. Nickel 200 shoulder bolts are commonly available with socket drivers. | • ASME • DIN 7379 / ISO 7379 • ISO 7370 |

Wedge Anchor Bolts Wedge Anchor Bolts | Nickel 200 wedge anchor bolts are a safe and secure way to attach equipment and other materials to concrete in corrosive environments. |

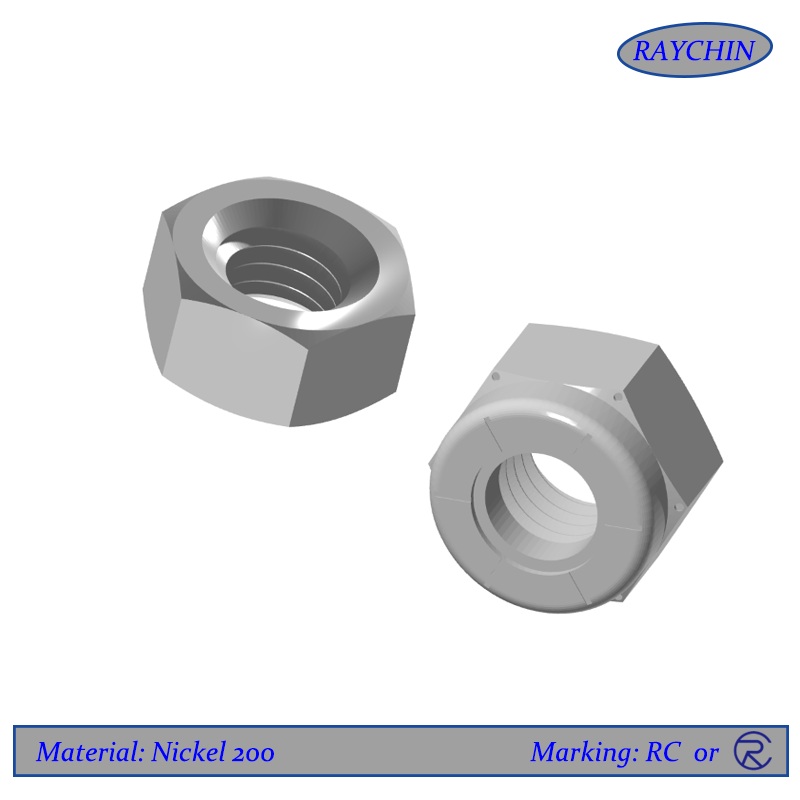

Nickel 200 Nuts

| Nickel 200 hex nuts are available in finished hex nuts, jam nuts and heavy hex nuts. | • ASME B18.16.3 • ASME B18.2.2 • DIN 439 / ISO 4035 • DIN 934 / ISO 4032 • DIN 986 | |

| Nickel 200 lock nuts are availalbe in all-metal (stover, flexloc, etc.) and polymer (nylon) insert styles. All-metal lock nuts are idea for high temperatures and even load distribution. Nickel 200 nylon insert lock nuts are an economic choice for temperatures under than 350°F. | • ASME B18.16.3M • DIN 980 / ISO 7042 / ISO 19513 • DIN 6923 / ISO 4161 • DIN 985 / ISO 10511 / ISO 7040 |

Nickel 200 Studs & Threaded Rod

Studs Studs | Nickel 200 studs are fully-threaded or partially-threaded lengths of rod that are under 12" long. Available in any custom length. | • ASME B18.31.2 • DIN 976 |

Threaded Rod Threaded Rod | Nickel 200 threaded rods are available in lengths greater than 1 foot. Minimum order quantity is a total of 6 feet of length. Maximum shipment length is 6 feet long. | • ASME B1.1 • DIN 975 |

Nickel 200 Washers

| Nickel 200 washers are offered in SAE, USS, MilSpec, oversized, and custom sizes. | • ASME 18.21.1 • SAE / USS • DIN 125 / ISO 7089 / ISO 7090 • DIN 126 / ISO 7091 | |

| Nickel 200 lock washers are available as split lock washers. | • ASME B18.21.1 • DIN 127 / ISO 7090 • DIN 6796 / ISO 10690 |