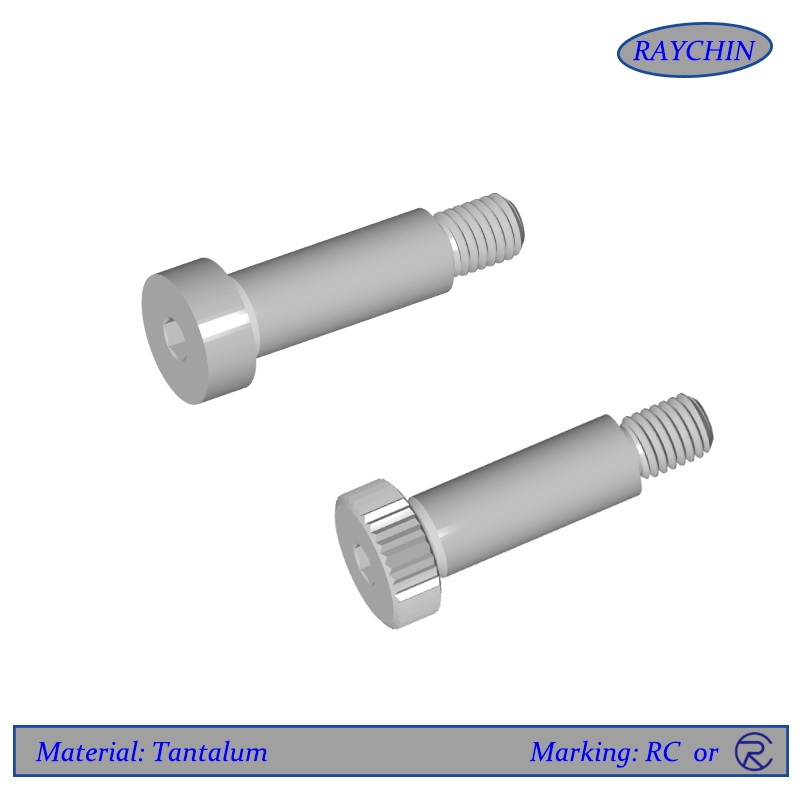

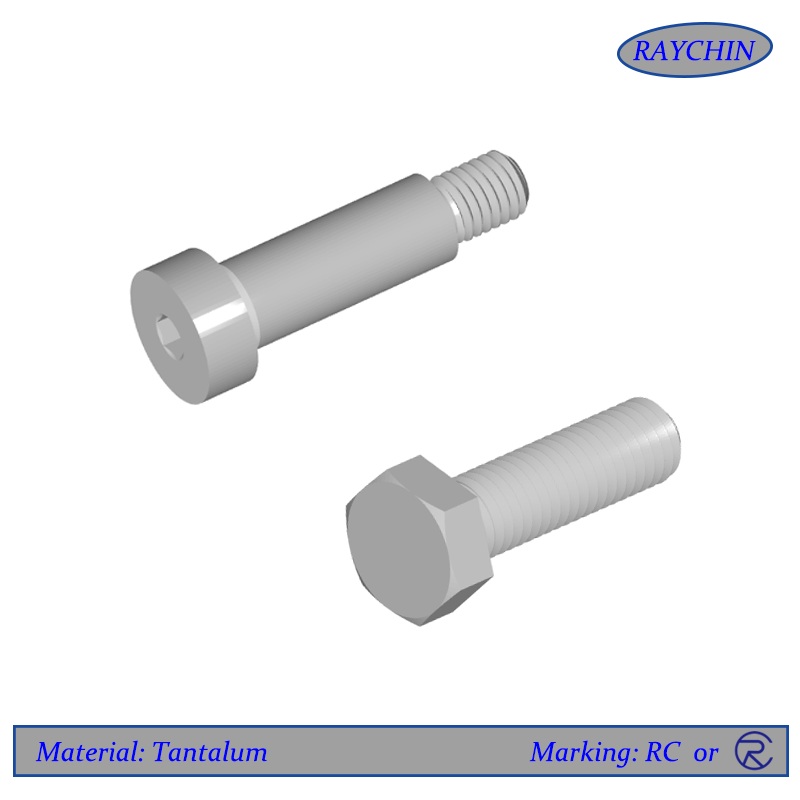

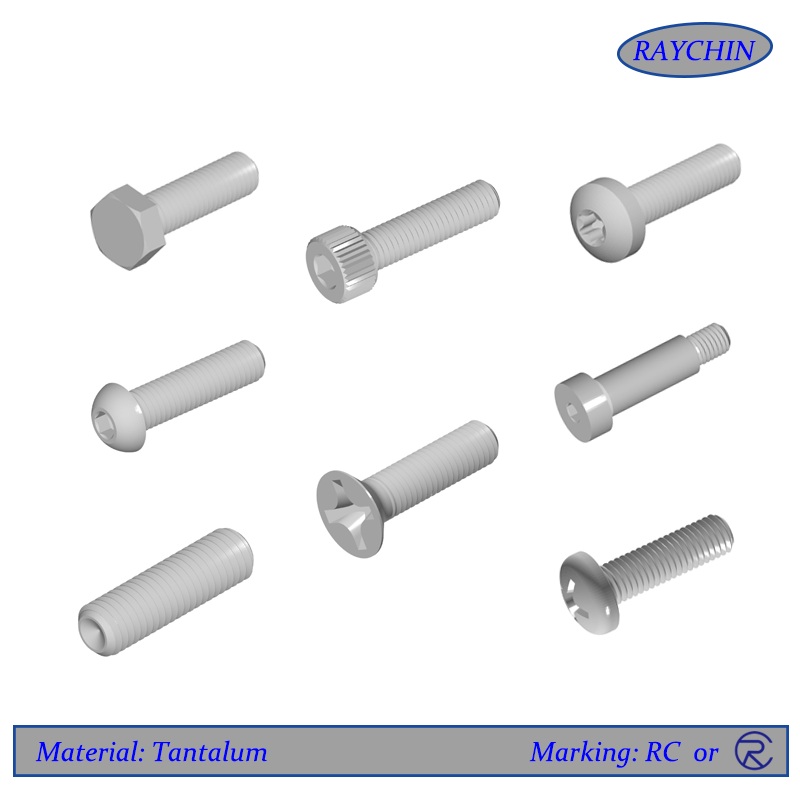

Tantalum Shoulder Bolts

Brand RAYCHIN

Product origin CHINA

Delivery time 5-35 DAYS

Tantalum shoulder bolts are best known for its unmatched corrosion resistance and chemical inertness. Tantalum bolts have a similar corrosion resistance to that of glass, but all of the typical mechanical and electrical properties of a metal.

Tantalum shoulder bolts are also extremely stable at high temperatures, since tantalum has a melting point around 3000°C. High temperature applications require vaccum or inert gas since tantalum may embrittle when used in oxygen rich environments above 250°C. Tantalum bolts are also one of the most bio-compatible metals available and is also radio-opaque due to its high density (16.68 g/cm3).

All tantalum shoulder bolts are available in commercially pure tantalum and tantalum 2.5% tungsten (Ta-2.5%W).

Tantalum Shoulder Bolts

Tantalum shoulder bolts are best known for its unmatched corrosion resistance and chemical inertness. Tantalum bolts have a similar corrosion resistance to that of glass, but all of the typical mechanical and electrical properties of a metal.

Tantalum shoulder bolts are also extremely stable at high temperatures, since tantalum has a melting point around 3000°C. High temperature applications require vaccum or inert gas since tantalum may embrittle when used in oxygen rich environments above 250°C. Tantalum bolts are also one of the most bio-compatible metals available and is also radio-opaque due to its high density (16.68 g/cm3).

All tantalum shoulder bolts are available in commercially pure tantalum and tantalum 2.5% tungsten (Ta-2.5%W).

When nickel, titanium or zirconium alloys are not enough...

· Immune to numerous acids and chemicals (corrosion tables)

· Better corrosion resistance than nickel alloys, titanium or zirconium

· High strength and stiffness in vacuum and inert gas up to 2000°C (3600°F)

· Can become brittle when used in oxygen above 300°C

· High purity and biocompatibilty

· Physical Properties

· Tantalum grades, specifications and chemistry

· Datasheet for tantalum

· Tantalum shoulder bolt features and benefits

Resources: Tantalum Torque Spec

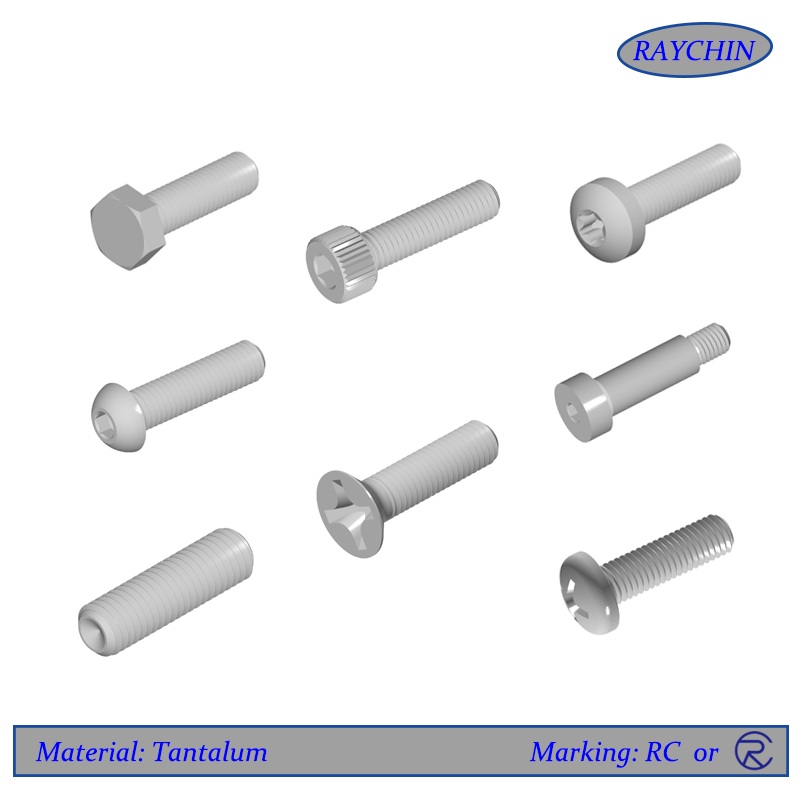

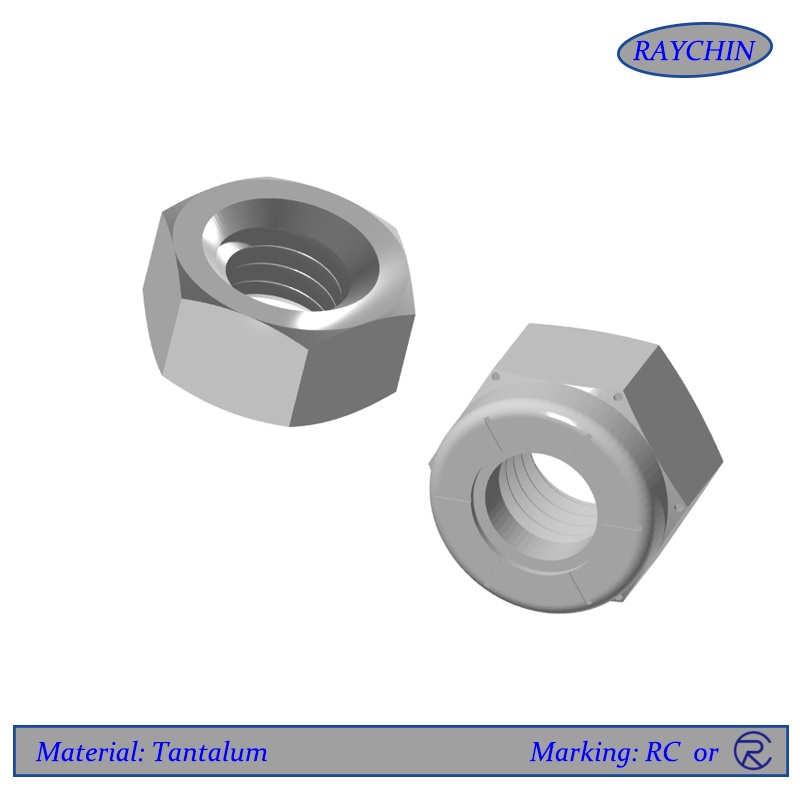

Bolt Types Available: Hex Bolts, Shoulder Bolts

Tantalum Shoulder Bolt Features and Benefits

Tantalum shoulder bolts, also called stripper bolts are a unique fastener with three main parts: head, shoulder, and thread. The head has the largest diameter and is where the torque is applied, typically with a socket driver. The shoulder is smooth and unthreaded, and has a set diameter and length. The shoulder’s role is to act as a shaft or dowel for rotating parts, axles for rolling parts, guides for sliding elements, and pivot points. The final part of a tantalum shoulder bolt is the threaded shaft. The threaded portion of a shoulder bolt has a major diameter slightly smaller than the shoulder diameter.

Tantalum Grades, Specifications and Chemistry

Tantalum (Commercially Pure)

Commercially pure tantalum metal is 99.95% pure tantalum has some o the best corrosion resistant properties of any metal. While its corrosion resistance is exceptional, it is relatively soft and mechanically similar in strength to copper.

Tantalum Specifications: UNS R05200, ASTM B521, B708

Tantalum (CP) | Ta | Nb | W | Mo | O | Ti | Ni | Fe | N | C | Si | H |

Max% | >99.95 | 0.100 | 0.050 | 0.020 | 0.015 | 0.010 | 0.010 | 0.010 | 0.010 | 0.010 | 0.010 | 0.010 |

Tantalum 2.5% Tungsten (Ta-2.5W)

This grade of tantalum alloyed with 2.5% tungsten provided better overall strength while maintaining its exception corrosion resistant properties. For tantalum fastener applications this is usually preferred.

Specifications: UNS R05252

Tantalum 2.5%W | Ta | W | Nb | Mo | O | Ti | Ni | Fe | N | C | Si | H |

Typical% | Bal | 2.5 | 0.50 | 0.020 | 0.015 | 0.010 | 0.010 | 0.010 | 0.010 | 0.010 | 0.005 | 0.002 |

Physical Properties

Density 16.6 g/cc

Melting Point 3290 K, 2996°C, 5462°F

Boiling Point 5731 K, 6100°C, 9856°F

Coefficient of Thermal Expansion (20°C) 6.5 x 10(-6) / °C

Electrical Resistivity (20°C) 13.5 microhms-cm

Electrical Conductivity 13% IACS

Specific Heat .036 cal/g/°C

Thermal Conductivity .13 cal/cm(2)/cm°C/sec

Tantalum Tensile Data

TANTALUM - Tensile Data

Temperature (°F) | Ultimate Tensile (ksi) | Yield Strength at 0.2% Offset (ksi) | Elongation % |

Room Temp. | 40.0 | 25.0 | 50.0 |

200 | 29.0 | 22.0 | |

400 | 28.0 | 12.0 | |

600 | 28.0 | 8.0 | |

800 | 27.0 | 2.5 |

TANTALUM 2.5% W - Tensile Data

Temperature (°F) | Ultimate Tensile (ksi) | Yield Strength at 0.2% Offset (ksi) | Elongation % |

Room Temp. | 50.0 | 35.0 | 25.0 |

200 | 48.0 | 30.0 | 15.0 |

400 | 42.0 | 27.4 | 10.0 |

485 | 40.0 | 25.5 | 10.0 |

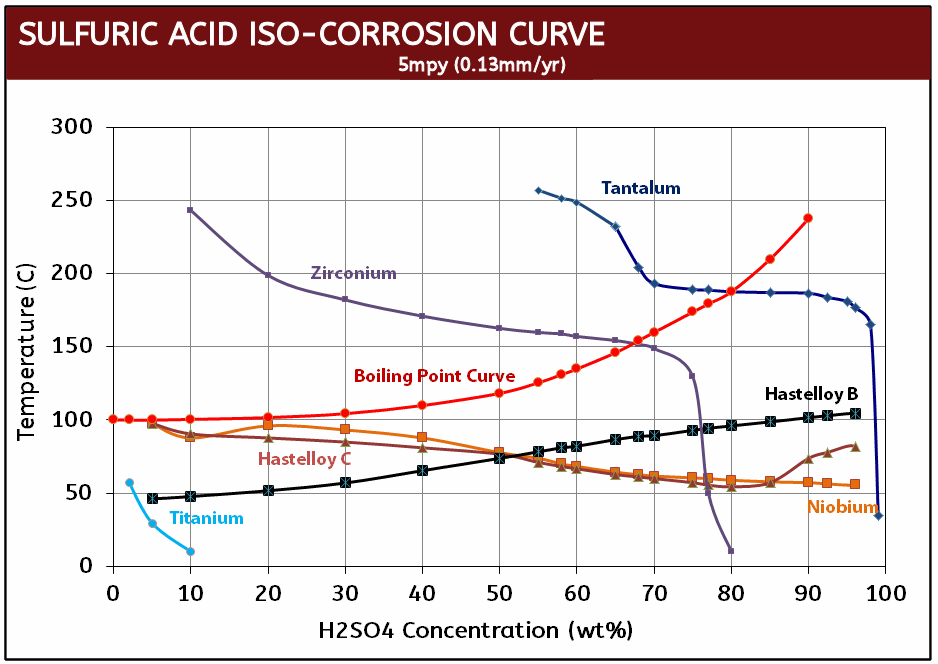

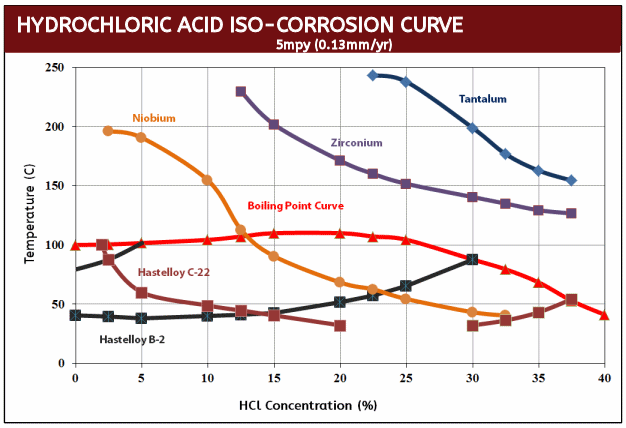

Tantalum Iso-Corrosion Curves

Tantalum Corrosion Resistance Table

TTantalum Corrosion Resistance Table

TANTALUM SHOWS A NIL CORROSION RATE TO THE FOLLOWING MEDIA For all temperatures up to at least 302F (150C) unless otherwise indicated | |||

Acetic acid | Chlorine, dry, <250°C (480°F) | Maleic acid | Potassium sulfate |

TANTALUM SHOWS LIMITED CORROSION RESISTANCE TO THE FOLLOWING MEDIA | |||

Air,>300°C (570°F) | Hydrogen, >300°C (570°F)Hydrogen fluoride | Potassium hydroxide, conc. | Sodium hydroxide, conc. |