Unique for its strength, lightness of weight and corrosion resistance

Excellent strength to weight ratio

Excellent strength to weight ratioPractically inert to chloride, chlorines and seawater

Mechanical Properties: tensile, yield & elongation charts

Titanium Grade 2, 5, 7 and 23 chemistry & specifications

Datasheets for Grade 2 and Grade 5

Titanium fastener styles

Titanium FAQ of the Week

Fastener stock & availability

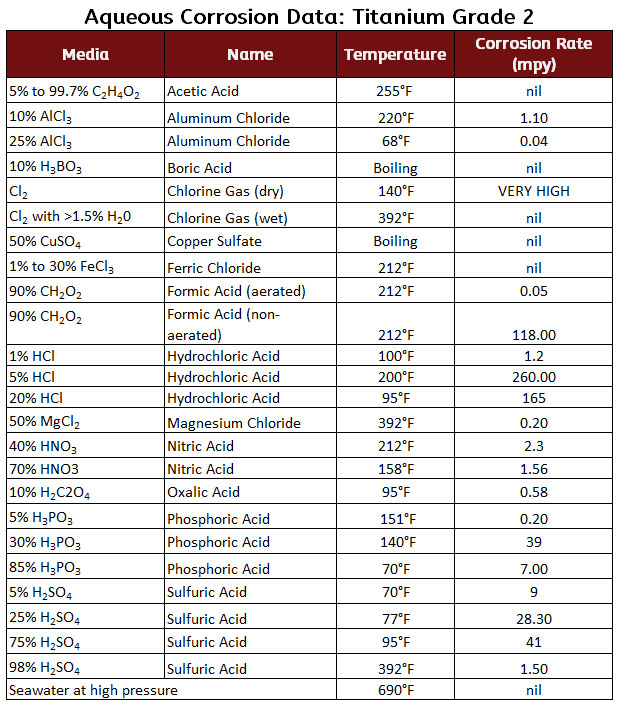

Corrosion Resistance

Saltwater

Perhaps the most notable attribute of titanium fasteners are their superior corrosion resistance to salt water / seawater. Titanium screws have the unique ability to rapidly regrow their protective passive layer in the presence of oxygen, giving them unparalleled resistance to salt water environments.

• Proven resistance in decades of polluted seawater

• Usable in ocean depths of a mile beneath the surface

• Resistant to high velocity, rapidly moving currents as well as stagnant seawater

• Not affected by the presence of sulfides in seawater

• Ideal for sea splash and tide zones

• Seawater resistant to temperatures as high as 500°F (260°C)

Chloride, Chlorine & Other Media

Similar to salt water, titanium’s strong, protective oxide film which regenerates in oxygen makes it extremely resistant to oxidizing environments, and chlorides solutions, including hypochlorites, chlorates, perchlorates, sodium chlorite, and chlorine dioxide. This protection holds true as long as moisture is present – which can be as little as 50ppm of moisture. Oxidizing environments in the absence of water can cause titanium to rapidly corrode or even ignite. Titanium screws are not resistant to reducing media and acids

Lightweight Strength

Not only are titanium grade 5 fasteners extremely strong, offering 148 ksi UTS and 138ksi yield they are also incredibly light. With a density of 4.51 g /cm3, titanium has on of the the highest strength-to-weight ratios available to industry. Titanium Grade 5 screws are 4 times stronger than 316 stainless steel at nearly half the weight. This makes titanium fasteners ideal for applications that require both lightness of weight and excellent strength such medical, military and sporting goods.

Which Grade is Best for Your Application?

The most common grades of of Titanium fasteners are Grade 2 (commercially pure Ti) and Grade 5 (Ti 6Al-4V - high strength). Still not sure? With decades of materials expertise and industrial experience, our engineers can help you select the best titanium fastener for your application.

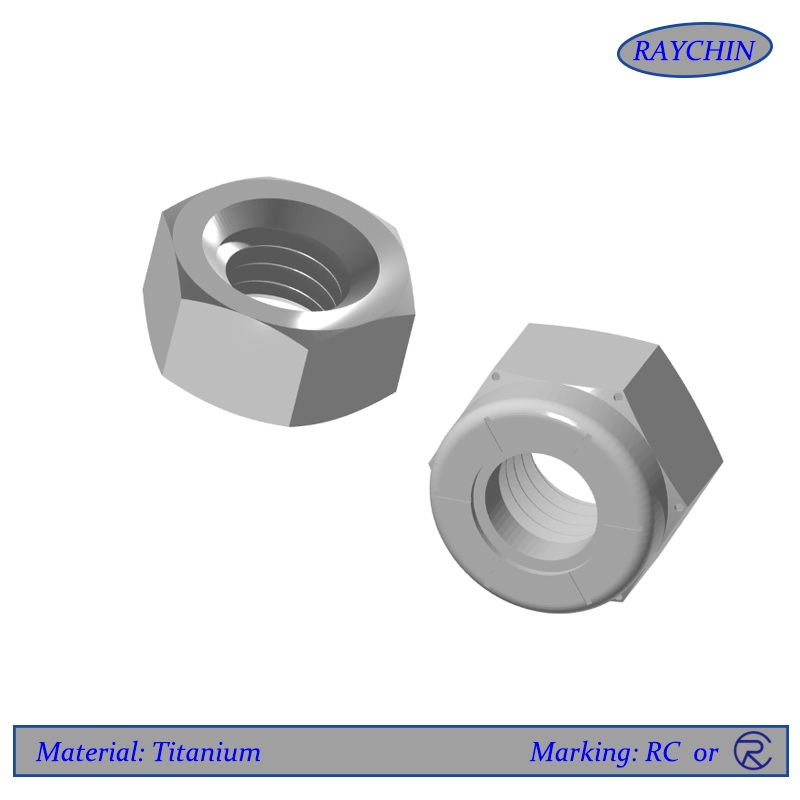

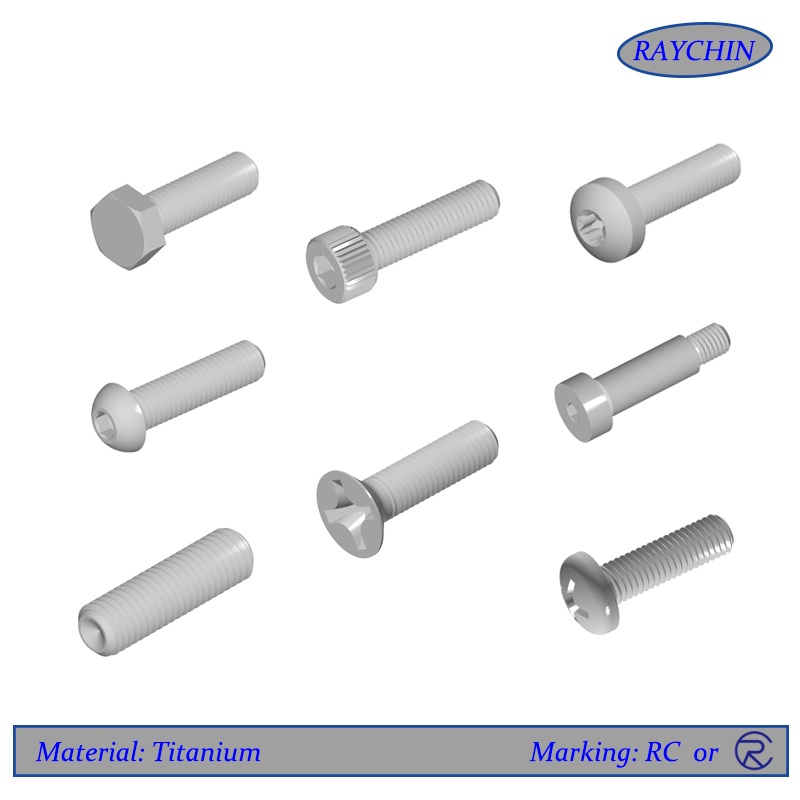

Titanium Fastener Styles

| Titanium Screws | 12 Point Screws, Button Head Cap Screws, Flat Head Screws, Hex Head Cap Screws, Pan Head Screws, Security Screws, Set Screws, Socket Head Cap Screws, Vented Screws |

|

| Titanium Bolts | Hex Head Bolts, Shoulder Bolts, Wedge Anchor Bolts | • DIN 931 • DIN 933 • ISO 4014 • ISO 4017 • ISO 7370 |

| Titanium Nuts | Hex Nuts, Lock Nuts | • DIN 439 / ISO 4035 • DIN 934 / ISO 4032 • DIN 985 / ISO 7040 • DIN 986 • DIN 980 / ISO 7042 / ISO 19513 • DIN 6923 / ISO 4161 |

| Titanium Studs/Rod | Studs, Threaded Rod, Weld Studs | • DIN 975 • DIN 976 |

| Titanium Washers | Flat Washers, Lock Washer | • DIN 125 / ISO 7089 / ISO 7090 • DIN 126 / ISO 7091 • DIN 127 / ISO 7090 • DIN 9021 / ISO 7093 |

| Titanium Hose Clamps | Medium Duty Hose Clamps, Worm Drive Hose Clamps |

Titanium Grades, Chemistry & Specifications

Titanium Grade 2 / UNS R50400 / 3.7035 (Commercially Pure)

Unalloyed titanium; Commercially pure titanium is the most common grade of titanium utilized throughout industry due to its ease of availability and good properties.

Titanium Grade 2 Specifications: UNS R50400, ASTM B 348, AMS 4921, ASTM F 67, ISO 5832-2, EN

3.7035, ASTM F467 (Nuts), ASTM F468 (Bolts, Screws, Studs)

Titanium Grade 2 | Ti | Fe | O | C | N | H |

Min% | - | - | - | - | - | - |

Max% | Bal | 0.30 | 0.25 | 0.08 | 0.03 | 0.015 |

Titanium Grade 5 (Ti 6Al-4V) / UNS R56400 / 3.7165

Known as the “workhorse” of the titanium alloys, Ti 6Al-4V, or Grade 5 titanium, is 2x stronger than titanium grade 2. This alloy offers high strength and light weight, useful formability and high corrosion resistance. Ti 6AI-4V finds many uses in the aerospace, medical, marine and chemical processing industries.

Titanium Grade 5 Specifications: UNS R56400, EN 3.7165, ASTM - B265, B348, B381, B861, F467 and F468, AMS - 4911, 4928, 4935, 4965 and 4967, MIL-T - 9046 and - 9047, EN 3.7165, ASTM F467 (Nuts), ASTM F468 (Bolts, Screws, Studs)

Titanium Grade 5 | Ti | Al | V | Fe | O | C | N | H |

Min% | - | 5.5 | 3.5 | - | - | - | - | - |

Max% | Bal | 6.75 | 4.50 | 0.30 | 0.20 | 0.08 | 0.05 | 0.0150 |

Titanium Grade 7 (Ti-0.15Pd) / UNS R52400 / 3.7235

Grade 7 is the most corrosion resistant of all titanium alloys and is typically used in chemical processes and production equipment components. Similar to Grade 2, but with the addition of 0.12 to 0.25% palladium, Grade 7 has enhanced corrosion resistance to reducing acids and localized attack in hot halides.

Titanium Grade 7 Specifications: ASTM - B265, B337, B338, B348, B363, B381, B861 and B862, EN 3.7235, ASTM F467 (Nuts), ASTM F468 (Bolts, Screws, Studs)

Titanium Grade 7 | Ti | Fe | Pd | O | C | N | H |

Min% | - | - | 0.12 | - | - | - | - |

Max% | Bal | 0.30 | 0.25 | 0.25 | 0.08 | 0.03 | 0.0150 |

Titanium Grade 23 (TI 6AL-4V ELI) / UNSR56401 / 3.7165

Titanium grade 23 or TI 6AL-4V ELI is an Extra Low Intersticial grade. This grade is similar to Grade 5, but because of the low intersticials, its mechanical properties are enhanced. This ELI grade is often found in more demanding medical device applications as well as industrial applications.

Titanium Grade 23 Specifications: UNS R52400, ASTM - B265, B348, B363, B381, B861, B862 andF136, AMS - 4907, 4930 and 4956, EN 3.7165, ASTM F467 (Nuts), ASTM F468 (Bolts, Screws, Studs)

Titanium Grade 23 | Ti | Al | V | Fe | O | C | N | H |

Min% | - | 5.5 | 3.5 | - | - | - | - | - |

Max% | Bal | 6.50 | 4.50 | 0.25 | 0.13 | 0.08 | 0.03 | 0.0125 |

Mechanical Properties

TITANIUM GRADE 2 - Tensile Data

Temperature (°F) | Ultimate Tensile (ksi) | Yield Strength at 0.2% Offset (ksi) | Elongation % |

Room Temp. | 70 | 50 | 28 |

212 | 56 | 37 | 31 |

392 | 41 | 28 | 37 |

572 | 33 | 18 | 43 |

752 | 27 | 13 | 38 |

842 | 26 | 11 | 34 |

TITANIUM GRADE 5 - Tensile Data

Temperature (°F) | Ultimate Tensile (Ksi) | Yield Strength at 0.2% Offset (ksi) | Elongation % |

Room Temp. | 13S | 128 | 14 |

300 | 121 | 105 | 16 |

500 | 110 | 93 | 17 |

700 | 100 | 82 | 18 |

TITANIUM GRADE 7 - Tensile Data

Temperature (°F) | Ultimate Tensile (Ksi) | Yield Strength at 0.2% Offset (ksi) | Elongation % |

Room Temp. | 50 | 40 | 20 |

200 | 57 | 40 | 28 |

400 | 41 | 24 | 41 |

600 | 32 | 15 | 38 |

Titanium's Resistance to Chlorine

GRADE 2 | ||

Media | Temperature °F | Corrosion Rate mpy (mm/y) |

Wet Chlorine | 50-130 | Nil-0.02 (0.001) |

Water Saturated, Chlorine Cell Gas | 190 | 0.055 (0.002) |

Dry Chlorine | 36 | Rapid Attack, Ignition |

Corrosion Data