-

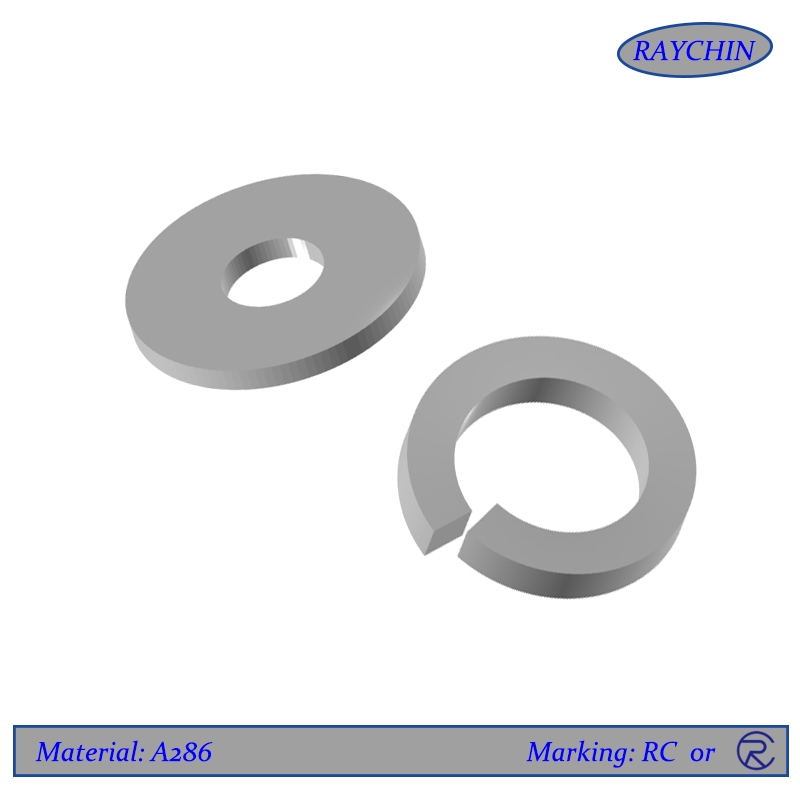

A286 Washers

A286 washers, also known as Alloy 660 washers are stainless steel alloy which contains iron, nickel and chromium. A286 washers are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 / Alloy 660 washers provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 washers are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. -

17-4 PH Studs

17-4 PH studs are made from a precipitation hardened stainless steel most known for its exceptional strength and its ability to maintain its mechanical properties to 600°F. Compared to 316 stainless steel, 17-4 PH studs yield strength is up over 4 times greater. When compared to Duplex 2205 studs, the yield strength of 17-4 PH can be up to 2-½ times greater.

Send Email Details

17-4 studs are available in 8 different aged (precipitation hardened) conditions offering a variety of mechanical properties (see below). In addition,Raychin offers 17-4PH studs per ASTM F593 Grade 660 to ensure specific yield and tensile strengths for sensitive applications. -

MP35N Studs

MP35N Studs

Send Email Details

MP35N studs are known for their extraordinary strength and are the strongest studs we offer at RAYCHIN. MP35N studs owe their extraordinary strength to a unique alloy combination of nickel, cobalt, chrome and molybdenum and have ultimate tensile strengths that range from 227 ksi to 294 ksi (with age hardening).

Beyond the strength of MP35N studs, they are also exhibit good corrosion resistance and can resist most mineral acids, hydrogen sulfide, seawater and salt spray environments.

MP35N studs are also resistant to high temperature oxidation and could operate in environments up to 800°F and still maintain much of its strength.

Applications where MP35N studs are often found are: aerospace, defense, marine, chemical processing, oil and gas and medical. -

Nitronic Studs

Nitronic is a high strength austenitic steel alloy that was designed for high temperature use. It offers good high temperature properties as well as good low-temperature impact resistance. In addition, Nitronic bolts also offer nearly double the yield strength of 300 series stainless steel. Nitronic fasteners are available in two alloy variations, Nitronic 50 and Nitronic 60, each offering different niche capabilities.

Send Email Details -

Zirconium Studs

Commercially pure zirconium studs, also known as zirconium 702, are most well-known for their superior corrosion resistance in some of the harshest environments that include:

Send Email Details

• Hydrochloric Acid• Sulfuric Acid• Formic Acid• Nitric Acid • Acetic Acid

It is also a metal that offers industry unique properties. It does not absorb neutrons, making it ideal for use in nuclear power and at low temperatures it is superconductive, making it ideal for super magnets. -

Waspaloy Studs

Waspaloy studs are known for their superb high strength at elevated temperatures. Waspaloy is a high performance nickel alloy combined with cobalt, chrome and molybdenum to create it’s unique combination of strength and high temperature stability.

Send Email Details

Similar to that of Inconel 718 studs, Waspaloy studs exceed the strength and stability of Inconel 718 at elevated temperatures beyond 1400°F. In addition, the oxidation resistance of Waspaloy studs make it an ideal materials for high temperature applications like gas turbines engines, and a variety of other aerospace components. -

Titanium Studs

Titanium fasteners are best known for being strong, lightweight, and corrosion resistant. They are critical to many industries including chlor alkali, marine, off-shore oil & gas, desalination, medical, and pulp and paper. Grade 2 and 5 are the most commonly used grades of titanium screws:

Send Email Details

• Grade 2 (UNS R50400 / 3.7035) :Commercially pure titanium and the most common grade for screws.

• Grade 5 (UNS R56400 / 3.7165): Superior strength-to-weight ratio for a unique combination of corrosion and high strength. -

Nickel 200 Studs

Nickel 200 (2.4060) fasteners are made from commercially pure nickel and are best known for their excellent performance in caustic alkali solutions such as caustic soda (NaOH). Nickel 200 also exhibits good performance in acids, especially HF (Hydrofluoric Acid - anhydrous) and hydroxides – but can be attacked by common solutions of hydrochloric or sulfuric acids.

Send Email Details -

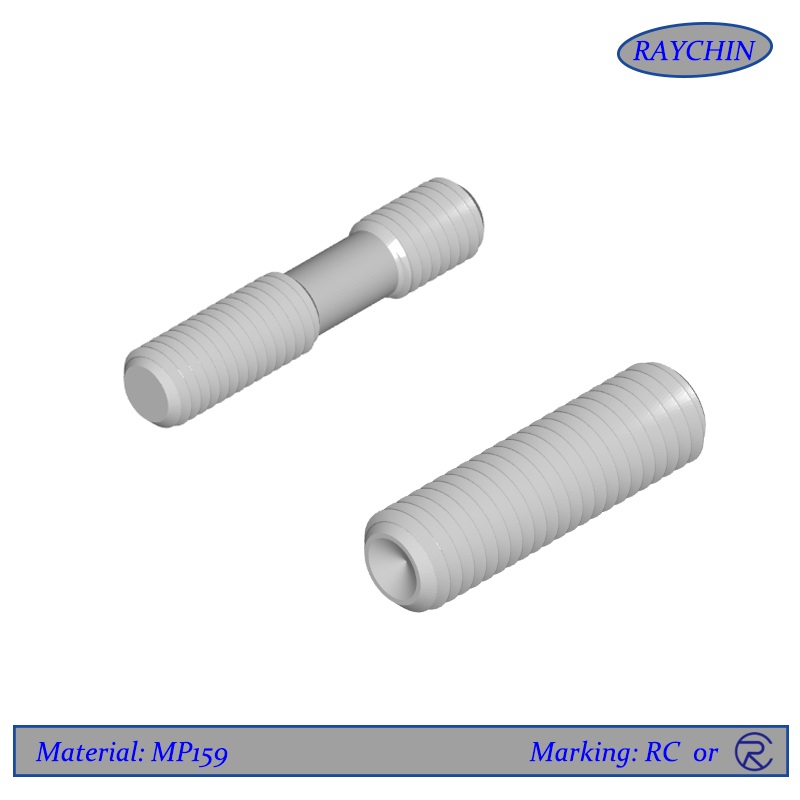

MP159 Studs

As aerospace engineering advances, so must the materials to meet the technological requirements of this industry. Studs made from MP159 have been developed to provide a solution to high temperature, high strength components. MP159 studs offer strength capabilities similar to other Cobalt Alloys (MP35N) but can be used at much higher temperatures - up to 1100°F, compared to MP35N’s usable limit of 800F. In addition, MP159 studs can be used beyond 1100°F in short term situations.

Send Email Details