-

Titanium Hex Bolts

Titanium fasteners are best known for being strong, lightweight, and corrosion resistant. They are critical to many industries including chlor alkali, marine, off-shore oil & gas, desalination, medical, and pulp and paper. Grade 2 and 5 are the most commonly used grades of titanium screws:

Send Email Details

• Grade 2 (UNS R50400 / 3.7035) :Commercially pure titanium and the most common grade for screws.

• Grade 5 (UNS R56400 / 3.7165): Superior strength-to-weight ratio for a unique combination of corrosion and high strength. -

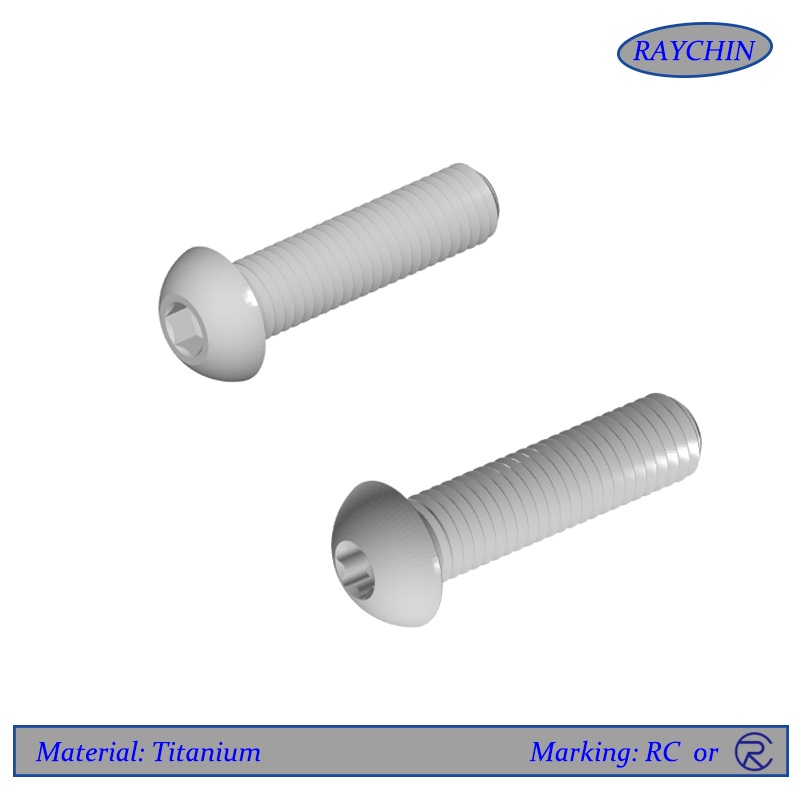

Titanium Button Head Cap Screws

Titanium fasteners are best known for being strong, lightweight, and corrosion resistant. They are critical to many industries including chlor alkali, marine, off-shore oil & gas, desalination, medical, and pulp and paper. Grade 2 and 5 are the most commonly used grades of titanium screws:

Send Email Details

• Grade 2 (UNS R50400 / 3.7035) :Commercially pure titanium and the most common grade for screws.

• Grade 5 (UNS R56400 / 3.7165): Superior strength-to-weight ratio for a unique combination of corrosion and high strength. -

Tantalum Hex Bolts

Tantalum hex head bolts are best known for its unmatched corrosion resistance and chemical inertness. Tantalum bolts have a similar corrosion resistance to that of glass, but all of the typical mechanical and electrical properties of a metal.

Send Email Details

Tantalum bolts are also extremely stable at high temperatures, since tantalum has a melting point around 3000°C. High temperature applications require vaccum or inert gas since tantalum may embrittle when used in oxygen rich environments above 250°C. Tantalum hex head bolts are also one of the most bio-compatible metals available and is also radio-opaque due to its high density (16.68 g/cm3).

All tantalum bolts are available in commercially pure tantalum and tantalum 2.5% tungsten (Ta-2.5%W). -

Molybdenum Hex Bolts

Molybdenum hex head bolts possesses a very high melting point of 2620°C, a low coefficient of thermal expansion and a high level of thermal conductivity. Because molybdenum bolts have the ability to withstand extremely high temperatures without changing shape, expanding or softening significantly, they are ideal for high strength / high temperature applications that are shielded from oxygen. Exposing molybdenum hex head bolts to oxygen above 600°C will cause them to readily oxidize.

Send Email Details -

Inconel Hex Bolts

Inconel® hex head bolts, like Inconel 600, 601,625,686,718 & 725 bolts, are a family of nickel-chromium-molybdenum alloys used for their high strength at elevated temperatures and good corrosion resistance. Because of its high thermal stability, Inconel can be used in service temperatures ranging from cryogenic to 2200°F (982°C). The high alloy content of Inconel hex head bolts enable it to withstand a wide variety of severe corrosive environments. In mild environments, such as the atmosphere, sea water, neutral salts, and alkaline media, there is almost no attack to Inconel bolts. In more severe corrosive environments the combination of nickel and chromium provides resistance to oxidizing chemicals, whereas the high nickel and molybdenum contents supply resistance to nonoxidizing environments.

Send Email Details -

A286 Threaded Rods

A286 threaded rod, also known as Alloy 660 rods are stainless steel alloy which contains iron, nickel and chromium. A286 rods are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 / Alloy 660 fasteners provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 threaded rods are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. -

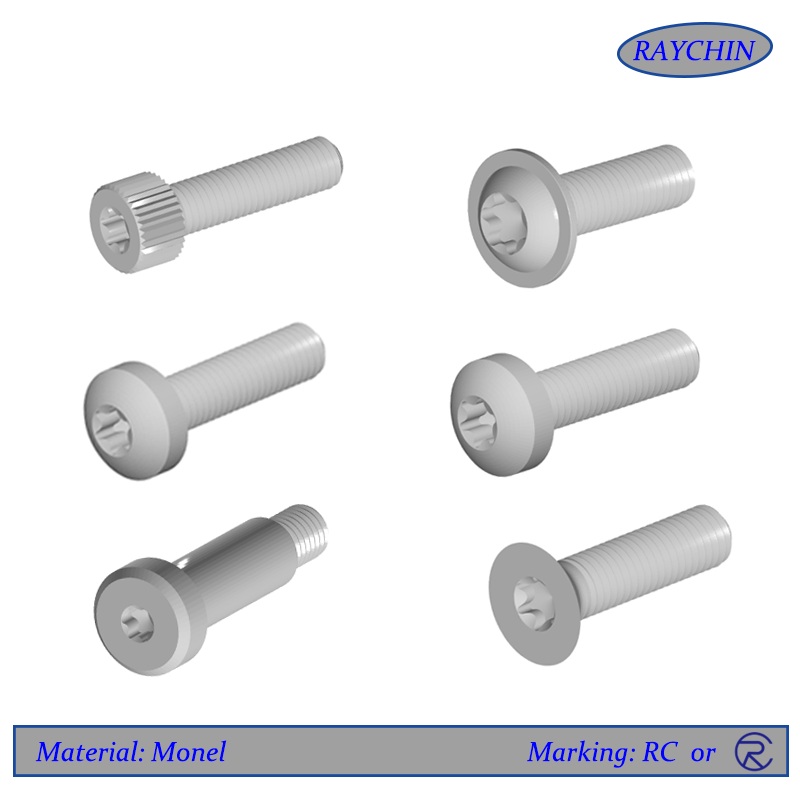

Monel Torx Screws

Monel® Torx screws, like Monel 400 and K500, are made from a nickel-copper alloy and exhibit high strength, toughness and good corrosion resistance over a wide temperature range. An outstanding characteristic of Monel Torx screws is that they offer exceptional resistance to hydrofluoric acid, a particularly tough acid to deal with, in all concentrations up to the boiling point. For hydrofluoric acid applications Monel screws are perhaps the most resistant of all commonly used specialty alloys.

Send Email Details -

Monel Socket Head Cap Screws

Monel® socket head cap screws, like Monel 400 and K500, are made from a nickel-copper alloy and exhibit high strength, toughness and good corrosion resistance over a wide temperature range. An outstanding characteristic of Monel socket head cap screws is that they offer exceptional resistance to hydrofluoric acid, a particularly tough acid to deal with, in all concentrations up to the boiling point. For hydrofluoric acid applications Monel socket head cap screws are perhaps the most resistant of all commonly used specialty alloys.

Send Email Details -

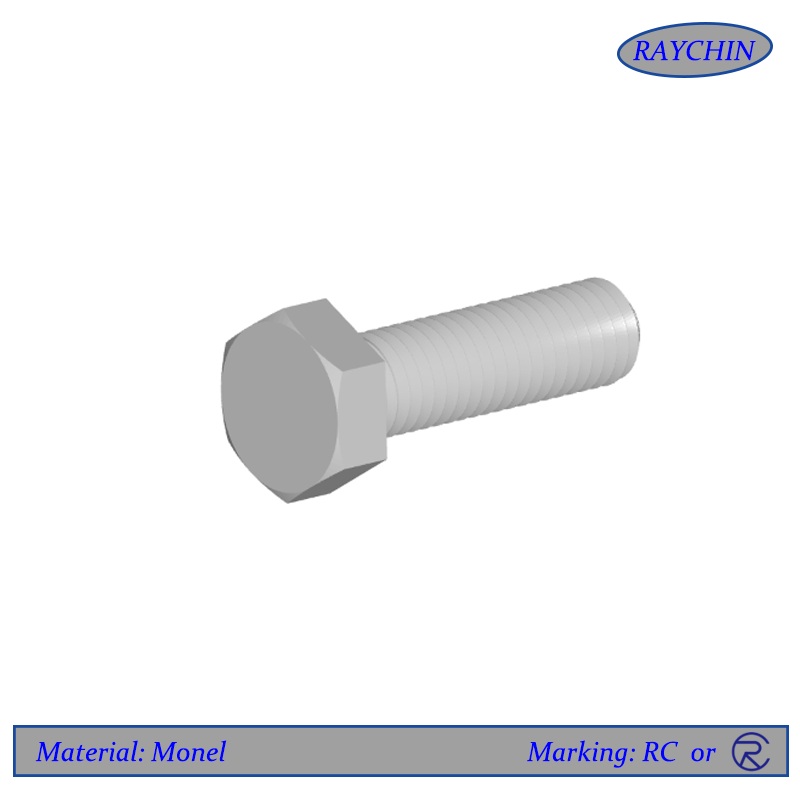

Monel Hex Cap Screws

Monel® hex head cap screws, like Monel 400 and K500, are made from a nickel-copper alloy and exhibit high strength, toughness and good corrosion resistance over a wide temperature range. An outstanding characteristic of Monel screws is that they offer exceptional resistance to hydrofluoric acid, a particularly tough acid to deal with, in all concentrations up to the boiling point. For hydrofluoric acid applications Monel hex head cap screws are perhaps the most resistant of all commonly used specialty alloys.

Send Email Details