-

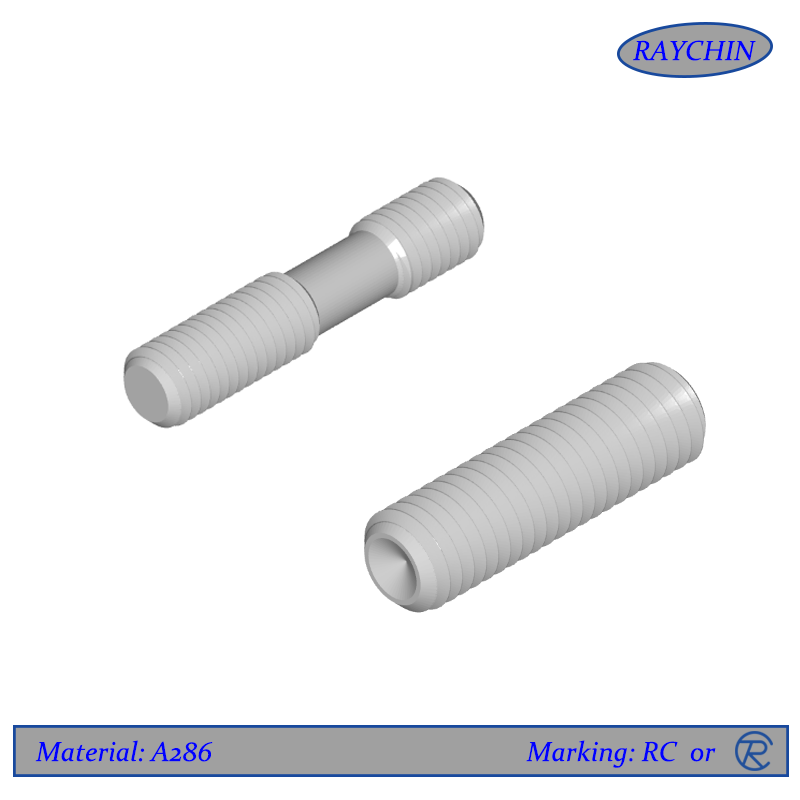

A286 Studs

A286 studs, also known as Alloy 660 studs are stainless steel alloy which contains iron, nickel and chromium. A286 studs are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 / Alloy 660 studs provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 studs are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. -

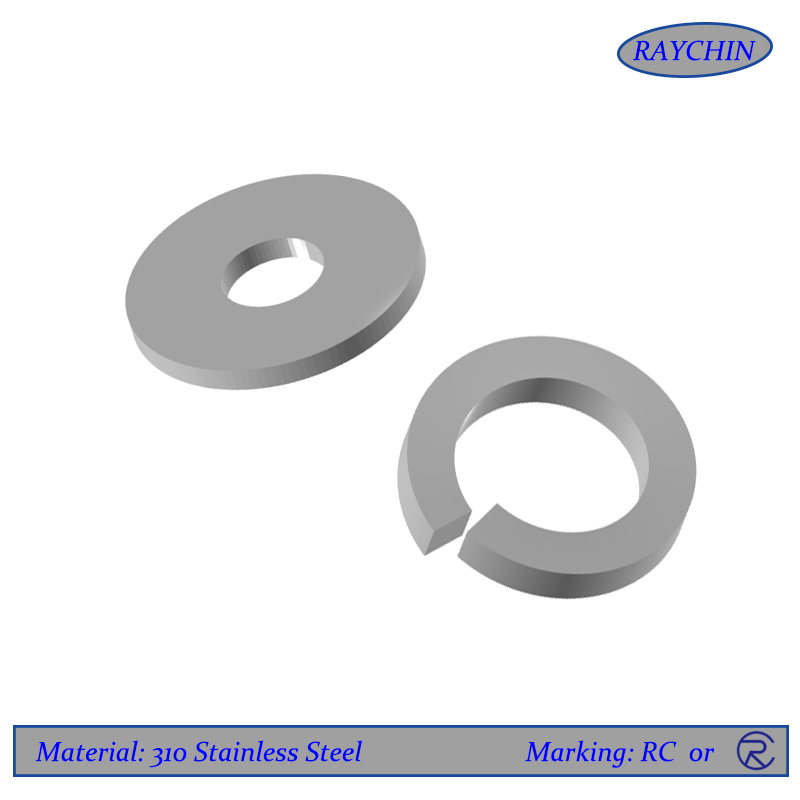

310 Stainless Steel Washers

Designed for high temperature applications, 310 stainless steel washers provide high temperature oxidation resistance to 2000°F under mild cyclic conditions. An economic alternative to nickel alloys like alloy 330 or Inconel, 310 washers provide slightly less strength and temperature resistance – but at a significantly lower price point. Alloy 310 can be used in moderately caburizing, moderately oxidizing, nitriding, cementing and thermal cycling applications when not used at the maximum service temperature. 310SS washers also have good resistance to sulfidation and other forms of hot corrosion. Although primarily known for its high temperature properties, 310 stainless steel also provides excellent performance at cryogenic temperatures, with toughness down to -450˚F. Though 310 is ideal for high temperature use, it should not be exposed to the severe thermal shock of repeated liquid quenching or where aqueous corrosive contaminants are present.

Send Email Details -

Titanium Security Screws

Titanium fasteners are best known for being strong, lightweight, and corrosion resistant. They are critical to many industries including chlor alkali, marine, off-shore oil & gas, desalination, medical, and pulp and paper. Grade 2 and 5 are the most commonly used grades of titanium screws:

Send Email Details

• Grade 2 (UNS R50400 / 3.7035) :Commercially pure titanium and the most common grade for screws.

• Grade 5 (UNS R56400 / 3.7165): Superior strength-to-weight ratio for a unique combination of corrosion and high strength. -

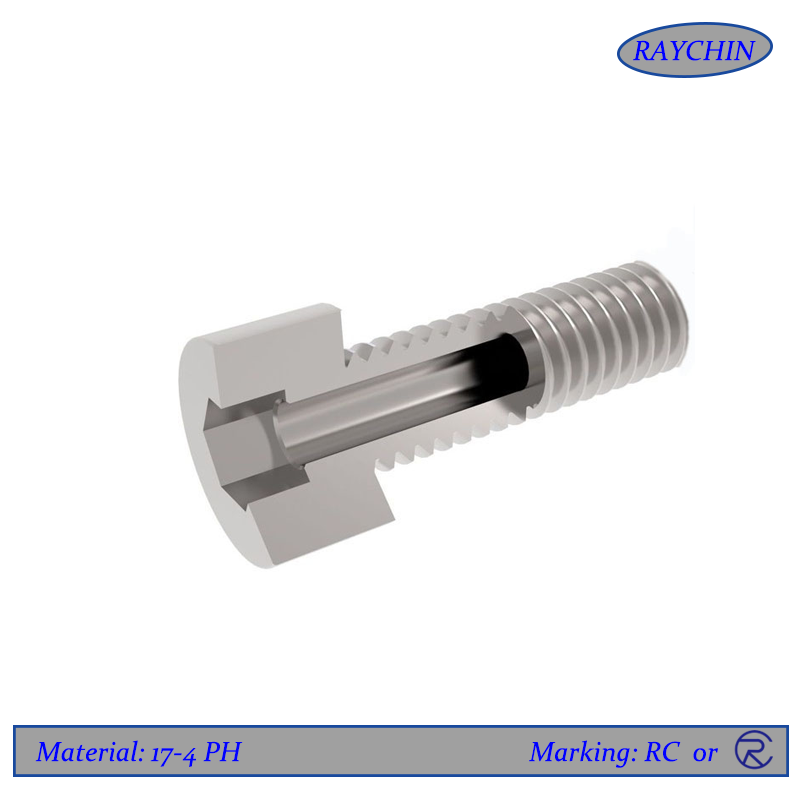

17-4 PH Vented Screws

17-4 PH vented screws are made from a precipitation hardened stainless steel most known for its exceptional strength and its ability to maintain its mechanical properties to 600°F. Compared to 316 stainless steel, 17-4 PH vented screws yield strength is up over 4 times greater. When compared to Duplex 2205 screws, the yield strength of 17-4 PH can be up to 2-½ times greater.

Send Email Details

17-4 vented screws are available in 8 different aged (precipitation hardened) conditions offering a variety of mechanical properties. -

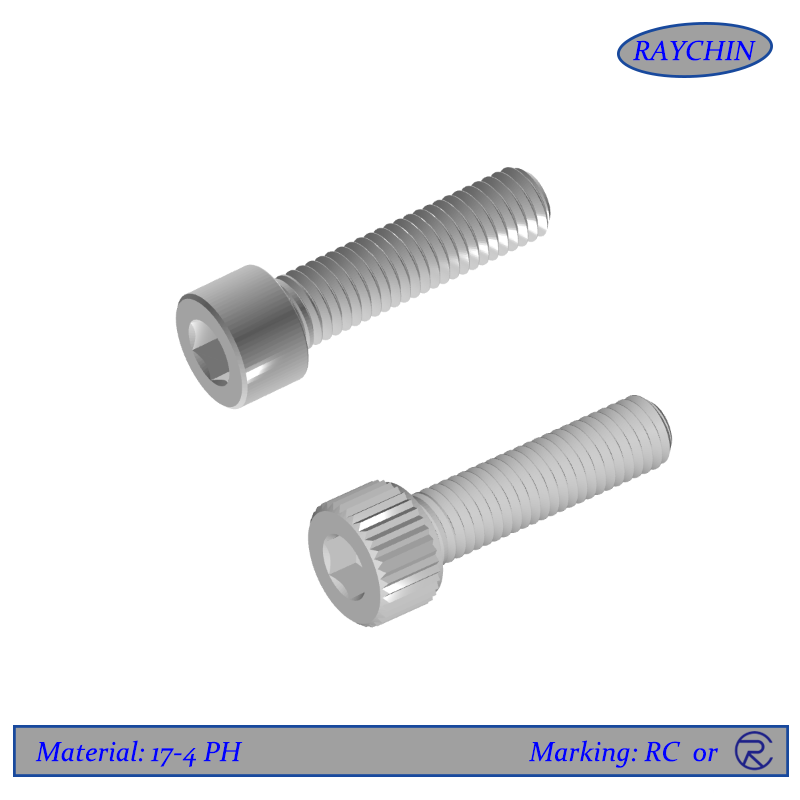

17-4 PH Socket Head Cap Screws

17-4 PH socket head cap screws are made from a precipitation hardened stainless steel most known for its exceptional strength and its ability to maintain its mechanical properties to 600°F. Compared to 316 stainless steel, 17-4 PH socket head cap screws yield strength is up over 4 times greater. When compared to Duplex 2205 socket head cap screws, the yield strength of 17-4 PH can be up to 2-½ times greater.

Send Email Details

17-4 socket head cap screws are available in 8 different aged (precipitation hardened) conditions offering a variety of mechanical properties. -

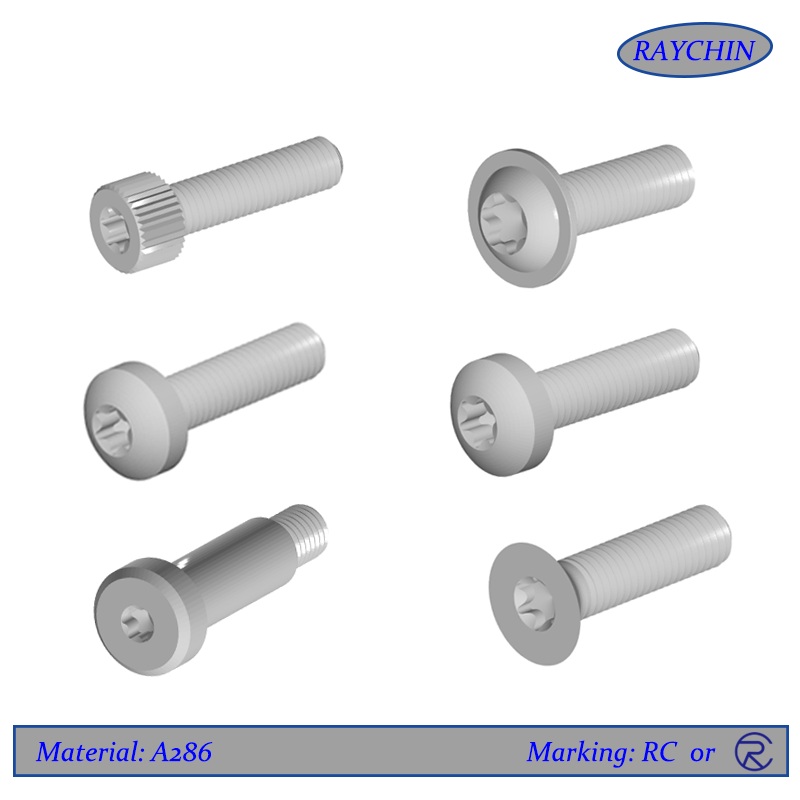

A286 Torx Screws

A286 screws, also known as Alloy 660 screws are stainless steel alloy which contains iron, nickel and chromium. A286 torx screws are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 screws provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 torx screws are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. For the most critical applications, we offer bolts screws per ASTM A453 Grade 660. This ensures tensile and rupture properties. -

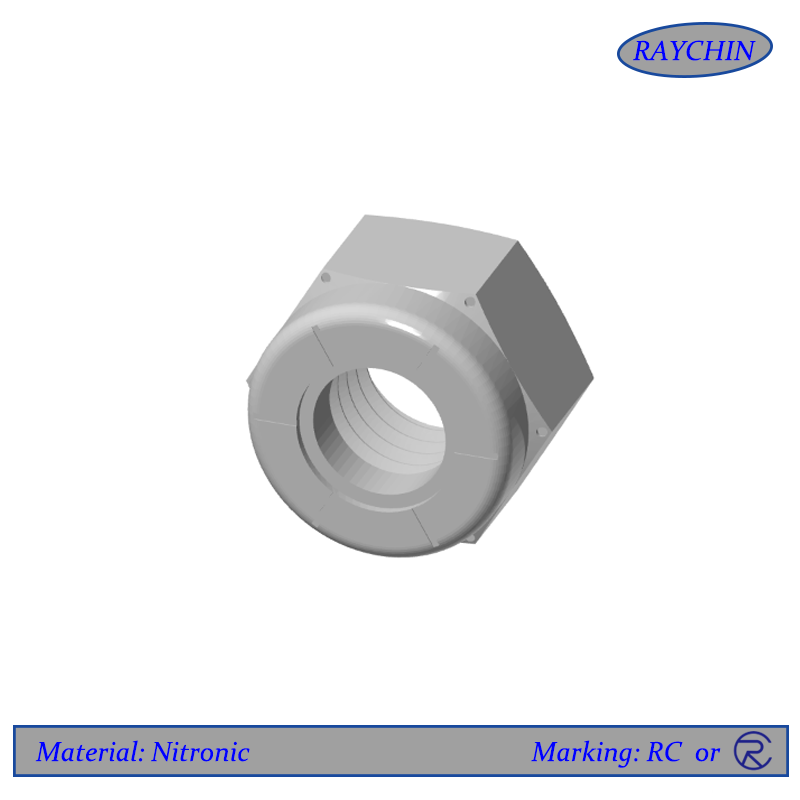

Nitronic Lock Nuts

Nitronic is a high strength austenitic steel alloy that was designed for high temperature use. It offers good high temperature properties as well as good low-temperature impact resistance. In addition, Nitronic bolts also offer nearly double the yield strength of 300 series stainless steel. Nitronic fasteners are available in two alloy variations, Nitronic 50 and Nitronic 60, each offering different niche capabilities.

Send Email Details -

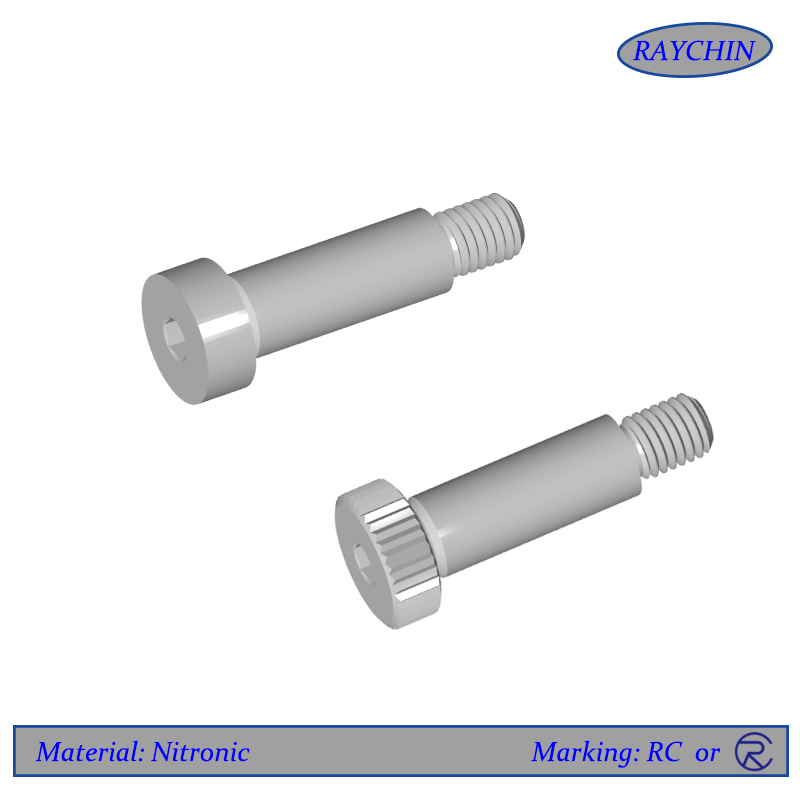

Nitronic Shoulder Bolts

Nitronic is a high strength austenitic steel alloy that was designed for high temperature use. It offers good high temperature properties as well as good low-temperature impact resistance. In addition, Nitronic bolts also offer nearly double the yield strength of 300 series stainless steel. Nitronic fasteners are available in two alloy variations, Nitronic 50 and Nitronic 60, each offering different niche capabilities.

Send Email Details -

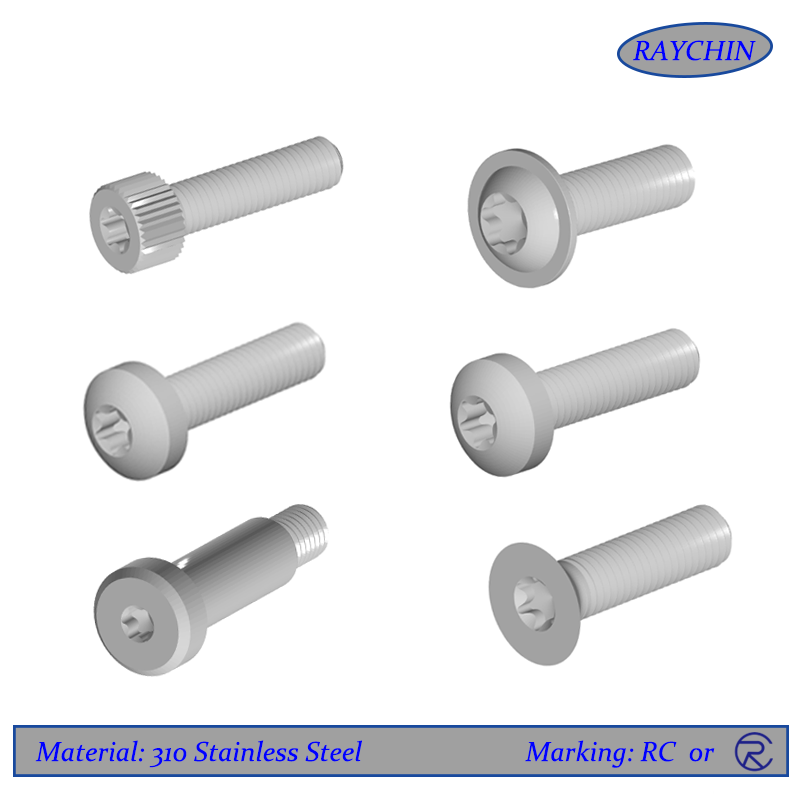

310 Stainless Steel Torx Screws

Designed for high temperature applications, 310 stainless steel torx screws provide high temperature oxidation resistance to 2000°F under mild cyclic conditions. An economic alternative to nickel alloys like alloy 330 or Inconel, 310 torx screws provide slightly less strength and temperature resistance – but at a significantly lower price point. Alloy 310 screws can be used in moderately caburizing, moderately oxidizing, nitriding, cementing and thermal cycling applications when not used at the maximum service temperature. 310SS torx screws also have good resistance to sulfidation and other forms of hot corrosion. Although primarily known for its high temperature properties, 310 screws also provide excellent performance at cryogenic temperatures, with toughness down to -450˚F. Though 310 is ideal for high temperature use, it should not be exposed to the severe thermal shock of repeated liquid quenching or where aqueous corrosive contaminants are present.

Send Email Details