-

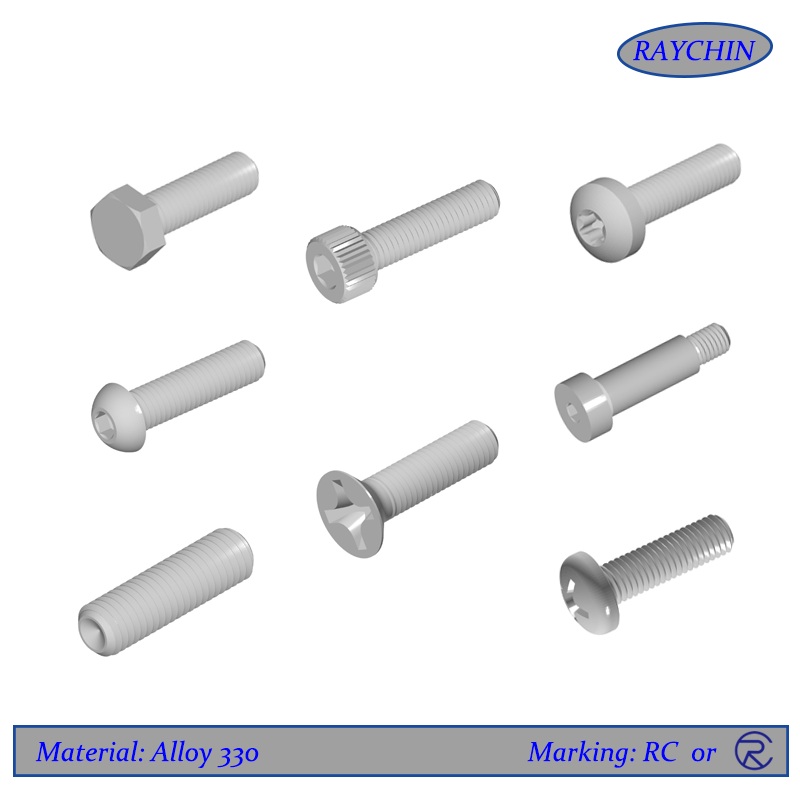

Alloy 330 Fasteners

Alloy 330 (1.4864) fasteners are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic, nickel-chromium-iron-silicon alloy, 330 fasteners also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Send Email Details -

Alloy 330 12 Point Screws

Alloy 330 12 point screws are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic, nickel-chromium-iron-silicon alloy, 330 12 point screws also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Send Email Details -

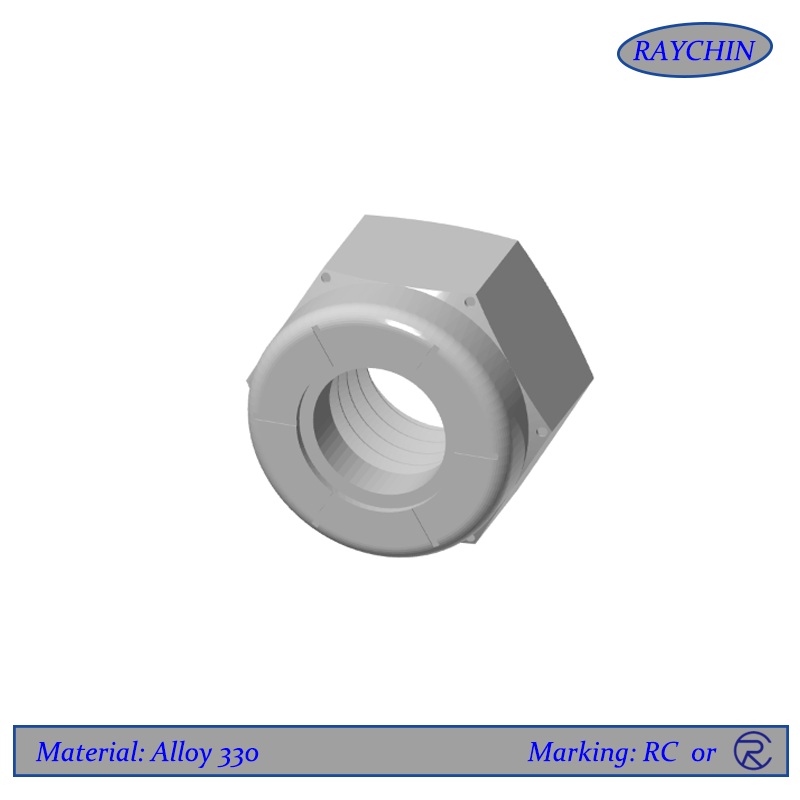

Alloy 330 Lock Nuts

Alloy 330 lock nuts are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic, nickel-chromium-iron-silicon alloy, 330 lock nuts also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Send Email Details -

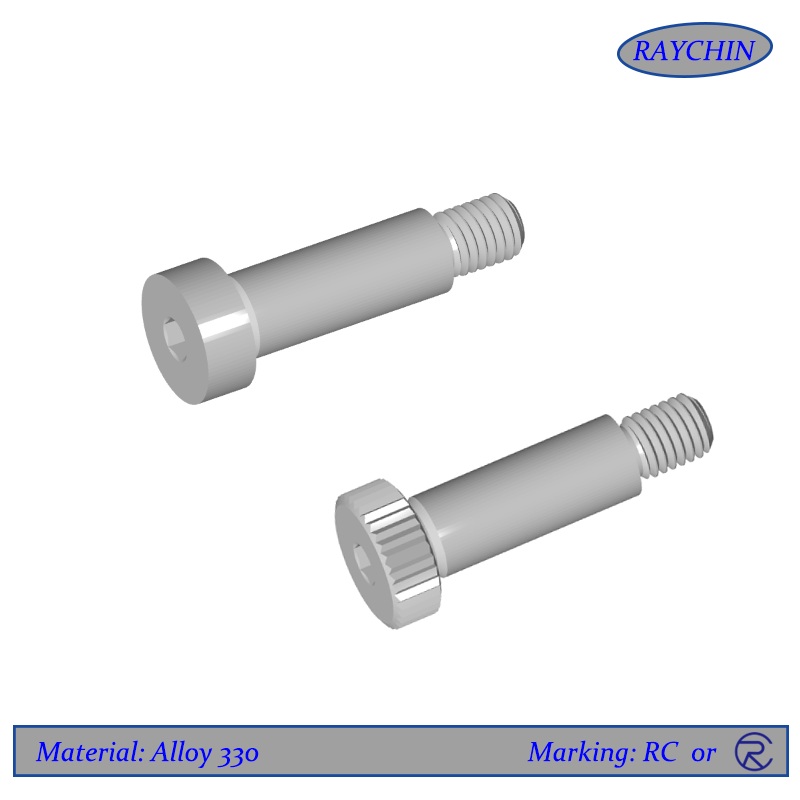

Alloy 330 Shoulder Bolts

Alloy 330 shoulder bolts are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic nickel-chromium-iron-silicon alloy, 330 shoulder bolts also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Send Email Details -

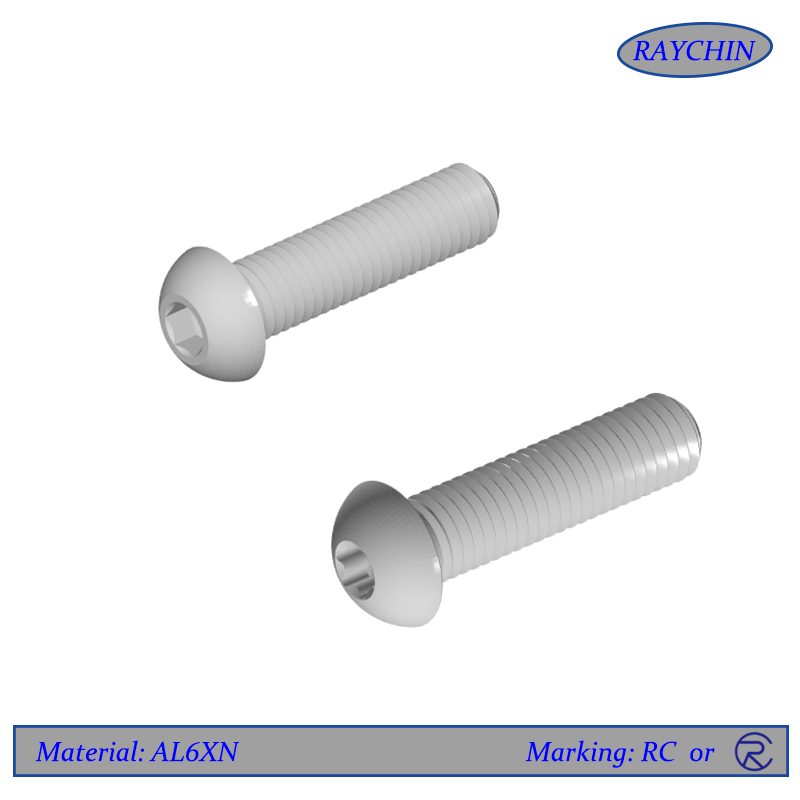

AL6XN Button Head Cap Screws

Originally developed to combat sea water corrosion, AL6XN has expanded its role as being good mid-range corrosion resistant alloy. AL6XN button head cap screws are a low carbon, high purity, nitrogen-bearing "super-austenitic" stainless alloy. Also considered a 6Moly alloy, AL6XN screws are similar in chemistry and capabilities to Alloy 926 and SMO 254. With a higher nickel and molybdenum content than Duplex 2205 and Super Duplex 2507, it delivers better corrosion resistance while giving a more cost effective alternative to nickel super alloys like Inconel or Hastelloy in moderately corrosive conditions.

Send Email Details -

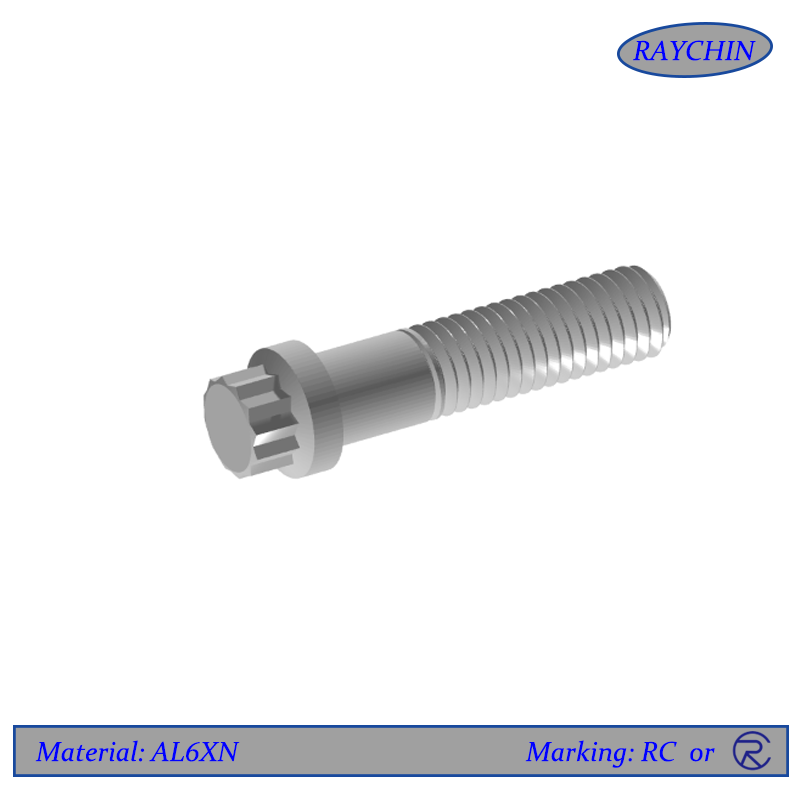

AL6XN 12 Point Screws

Originally developed to combat sea water corrosion, AL6XN has expanded its role as being good mid-range corrosion resistant alloy. AL6XN 12 point screws are a low carbon, high purity, nitrogen-bearing "super-austenitic" stainless alloy. Also considered a 6Moly alloy, AL6XN screws are similar in chemistry and capabilities to Alloy 926 and SMO 254.With a higher nickel and molybdenum content than Duplex 2205 and Super Duplex 2507, it delivers better corrosion resistance while giving a more cost effective alternative to nickel super alloys like Inconel or Hastelloy in moderately corrosive conditions.

Send Email Details -

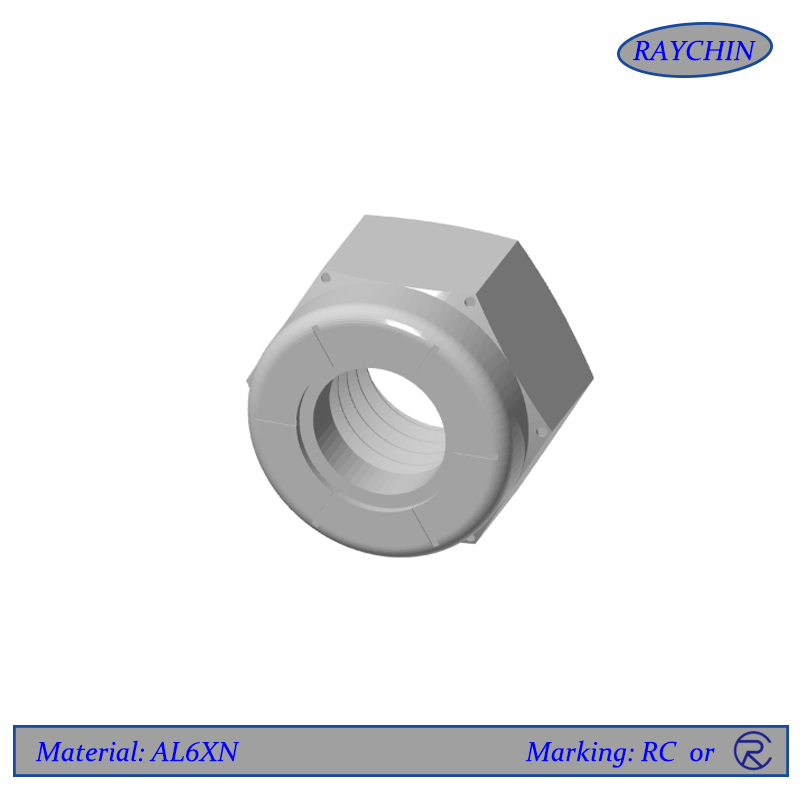

AL6XN Lock Nuts

Originally developed to combat sea water corrosion, AL6XN has expanded its role as being good mid-range corrosion resistant alloy. AL6XN lock nuts are a low carbon, high purity, nitrogen-bearing "super-austenitic" stainless alloy. Also considered a 6Moly alloy, AL6XN nuts are similar in chemistry and capabilities to Alloy 926 and SMO 254.With a higher nickel and molybdenum content than Duplex 2205 and Super Duplex 2507, it delivers better corrosion resistance while giving a more cost effective alternative to nickel super alloys like Inconel or Hastelloy in moderately corrosive conditions.

Send Email Details -

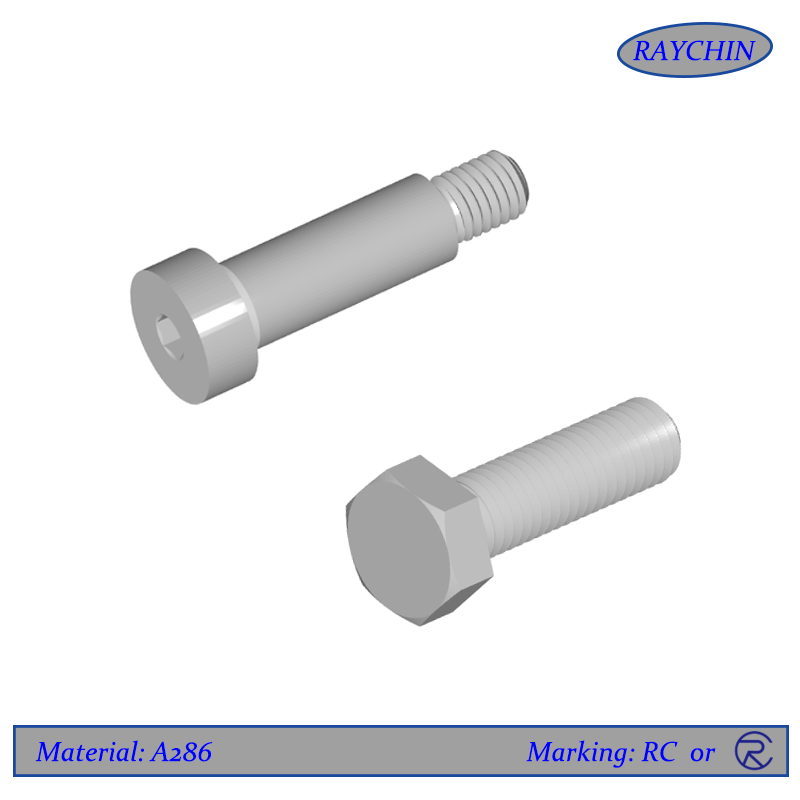

A286 Bolts

A286 (1.4980) bolts, also known as Alloy 660 bolts are stainless steel alloy which contains iron, nickel and chromium. A286 bolts are known for their high strength, creep resistance and oxidation resistance at elevated temperatures once age hardened. As a result, A286 bolts provide high levels of strength from room temperature up to about 1300°F (700°C).

Send Email Details

A286 bolts are also mildly corrosion resistant. While they should not be used for strong acid environments, they provide excellent oxidation resistance up to 1500°F (815°C) in conditions that would typically be found in high temperature exhaust streams. -

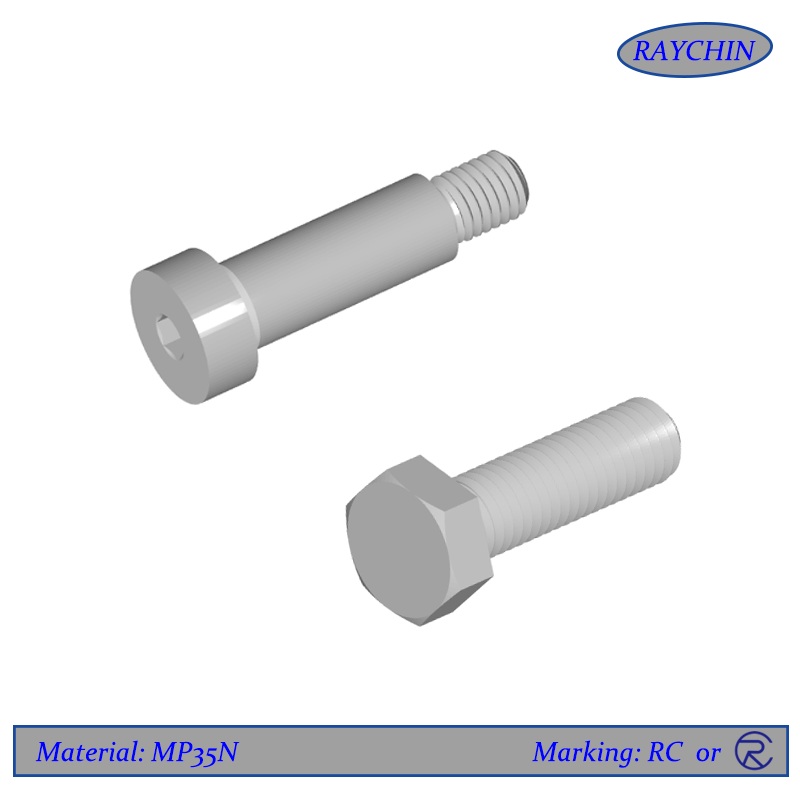

MP35N Bolts

MP35N (2.4999) bolts are known for their extraordinary strength and are the strongest bolts we offer at RAYCHIN. MP35N bolts owe their extraordinary strength to a unique alloy combination of nickel, cobalt, chrome and molybdenum and have ultimate tensile strengths that range from 227 ksi to 294 ksi (with age hardening).

Send Email Details

Beyond the strength of MP35N bolts, they are also exhibit good corrosion resistance and can resist most mineral acids, hydrogen sulfide, seawater and salt spray environments.

MP35N bolts are also resistant to high temperature oxidation and could operate in environments up to 800°F and still maintain much of its strength.