-

Inconel 12 Point Screws

Inconel® 12 point screws, like Inconel 600, 601,625,686,718 & 725 screws, are a family of nickel-chromium-molybdenum alloys used for their high strength at elevated temperatures and good corrosion resistance. Because of its high thermal stability, Inconel can be used in service temperatures ranging from cryogenic to 2200°F (982°C). The high alloy content of Inconel screws enable it to withstand a wide variety of severe corrosive environments. In mild environments, such as the atmosphere, sea water, neutral salts, and alkaline media, there is almost no attack to Inconel 12 point screws. In more severe corrosive environments the combination of nickel and chromium provides resistance to oxidizing chemicals, whereas the high nickel and molybdenum contents supply resistance to nonoxidizing environments.

Send Email Details -

Alloy 330 12 Point Screws

Alloy 330 12 point screws are specifically designed for high temperature furnace applications such as vacuum furnaces, heat treating and brazing applications. The most prized trait of alloy 330 is its ability perform under cyclic conditions of temperature extremes from heating and cooling; as well as in alternate carburizing and oxidizing atmospheres. An austenitic, nickel-chromium-iron-silicon alloy, 330 12 point screws also offer industry a low coefficient of expansion, excellent ductility, and high strength.

Send Email Details -

AL6XN 12 Point Screws

Originally developed to combat sea water corrosion, AL6XN has expanded its role as being good mid-range corrosion resistant alloy. AL6XN 12 point screws are a low carbon, high purity, nitrogen-bearing "super-austenitic" stainless alloy. Also considered a 6Moly alloy, AL6XN screws are similar in chemistry and capabilities to Alloy 926 and SMO 254.With a higher nickel and molybdenum content than Duplex 2205 and Super Duplex 2507, it delivers better corrosion resistance while giving a more cost effective alternative to nickel super alloys like Inconel or Hastelloy in moderately corrosive conditions.

Send Email Details -

254 SMO 12 Point Screws

254 SMO 12 point screws are ideal when you need higher torque than socket head cap screws offer. These screws are available in 1/4" diameter or larger. The only drawback is 12 point screws are less economical and require a higher minimum quantity due to the complexity of production.

Send Email Details -

12 Point Bolts

12 Point Bolts RAYCHIN is a manufacturer and worldwide supplier of standard & custom fasteners(12 Point Bolts) including those manufactured from the following materials: Hastelloy® C-276, Hastelloy® C-22, Hastelloy® B-2, Hastelloy® G-30, Monel® 400, Monel® K-500, Inconel® 600, Inconel® 625, Inconel® 718, Incoloy® A-286, Titanium Grade 2, Titanium Grade 5, Titanium Grade 7, Nickel 200, Nickel 200, Aluminum, Molybdenum, Nimonic, Nitronic, Tantalum, Tungsten, Waspaloy, Zirconium, Duplex S31803, Duplex S32205 and Super Duplex S32750, etc.

Send Email Details -

Monel 12 Point Screws

Monel® 12 point screws, like Monel 400 and K500, are made from a nickel-copper alloy and exhibit high strength, toughness and good corrosion resistance over a wide temperature range. An outstanding characteristic of Monel screws is that they offer exceptional resistance to hydrofluoric acid, a particularly tough acid to deal with, in all concentrations up to the boiling point. For hydrofluoric acid applications Monel screws are perhaps the most resistant of all commonly used specialty alloys. Monel alloy 400 & K500 12 point screws also exhibit excellent corrosion resistance in marine applications and have reasonable corrosion resistance to sulfuric and hydrochloric acids under reducing conditions. Because of these characteristics, Monel nickel alloy 12-point screws are often found in marine and chemical processing applications.

Send Email Details -

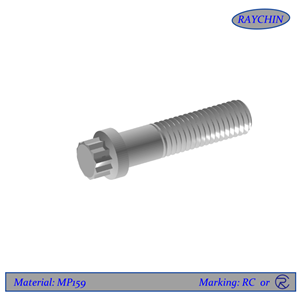

MP159 12 Point Screws

As aerospace engineering advances, so must the materials to meet the technological requirements of this industry. Screws made from MP159 have been developed to provide a solution to high temperature, high strength components. MP159 12 point screws offer strength capabilities similar to other Cobalt Alloys (MP35N) but can be used at much higher temperatures - up to 1100°F, compared to MP35N’s usable limit of 800F. In addition, MP159 screws can be used beyond 1100°F in short term situations.

Send Email Details -

MP35N 12 Point Screws

MP35N 12 point screws are known for their extraordinary strength and are the strongest screws we offer at Extreme Bolt. MP35N screws owe their extraordinary strength to a unique alloy combination of nickel, cobalt, chrome and molybdenum and have ultimate tensile strengths that range from 227 ksi to 294 ksi (with age hardening). Beyond the strength of MP35N 12 point screws, they are also exhibit good corrosion resistance and can resist most mineral acids, hydrogen sulfide, seawater and salt spray environments. MP35N screws are also resistant to high temperature oxidation and could operate in environments up to 800°F and still maintain much of its strength.

Send Email Details -

Incoloy 12 Point Screws

Not to be confused with Inconel, Incoloy 12 point screws are made of a nickel alloy which contains iron and a lower content of nickel. Incoloy is essentially a more economical option to Inconel, yet with more restricted corrosion resistance and temperature limits. Typically, Incoloy is an ideal material for long-term exposure in high temperature environments due to its oxidation, carburization and creep resistance. Incoloy is widely used for its resistance to seawater, brine, sour gas and high chloride environments at elevated temperatures, which make it a popular choice in the oil and gas and power industries.

Send Email Details